Coal slurry oil fuel engine oil composition

A technology of engine oil and coal slurry oil, which is applied in the direction of lubricating composition, etc., can solve the problems of aggravated parts wear, high cost, deterioration of injection and combustion quality, etc., and achieve the effects of preventing sticking, good low-temperature starting performance, and suppressing black sludge generated effect

Active Publication Date: 2014-10-08

GUANGXI UNIV

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The finer the particle size, the better the combustion, but the higher the cost; the larger the particle size, the lower the cost, but the quality of injection and combustion deteriorates, and at the same time, the wear of parts is increased

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

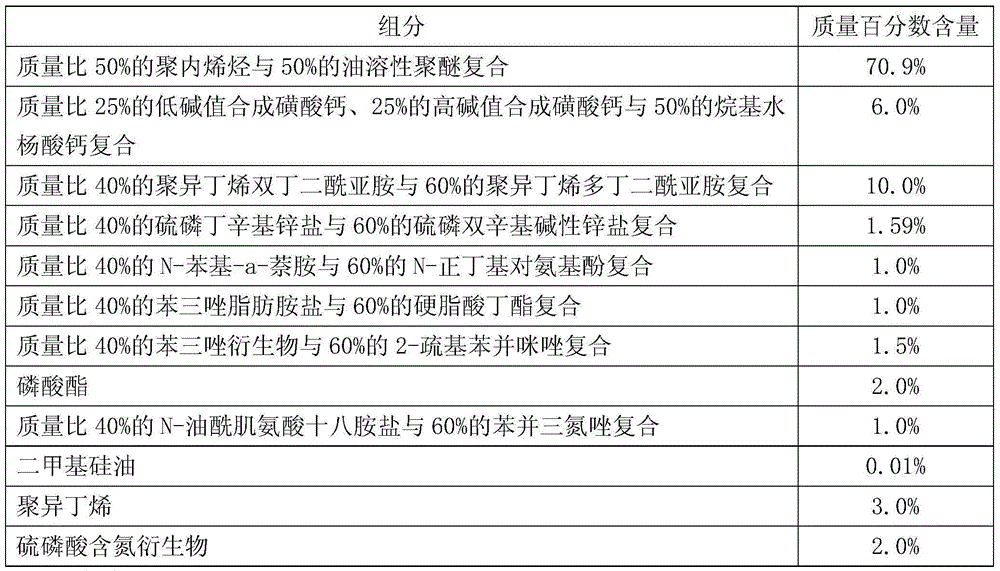

[0028] It is formed by blending the following components in mass percentage:

[0029]

[0030] The main physical and chemical index of embodiment 1 product:

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a coal slurry oil fuel engine oil composition. According to the invention, the composition adopts polyinternalolefins and oil-soluble polyether as base oil combined with multiple complex additives including a wear-resistant agent, an antioxidant preservative, an anti-foaming agent, a viscosity index improver, a metal deactivating agent, a friction improver, an antirust agent, a clearing agent, a dispersing agent, an oiliness additive, an antioxidant, and an antiwear agent. The engine oil composition has excellent clearing and dispersion effects, and is capable of preventing adhesion of a piston ring and keeping an engine clean; good viscosity-temperature characteristics, excellent base value retentivity and oil viscosity ascending ability can inhibit the generation of black oil sludge so that the engine is relatively clean; the coal slurry oil fuel engine oil composition has excellent high-temperature oxidization resistance stability, high-shear stability and rubber compatibility, good low-temperature starting property and excellent fuel economy and no corrosion and rustiness to moving components, and is capable of ensuring that the oil products keep enough oil film strength and reducing wear and evaporation loss.

Description

technical field [0001] The invention belongs to the field of internal combustion engine lubricants, in particular to a coal slurry oil fuel engine oil composition. Background technique [0002] Coal slurry oil is oil (COM) in which dry coal powder is mixed with diesel oil or heavy oil into a slurry. Usually, the particle size of pulverized coal is generally 1-6um, and the largest one is generally controlled below 15um, with an average of about 2um. The finer the particle size, the better the combustion, but the higher the cost; the larger the particle size, the lower the cost, but the quality of injection and combustion deteriorates, and at the same time, the wear of parts is increased. After diesel oil contains coal powder, the viscosity increases; the higher the coal content, the greater the viscosity, and the higher the temperature, the greater the noise and vibration, and the greater the difference in viscosity between diesel and diesel. The chemical composition of COM...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04

Inventor 黄福川黄孝平黄伊琳邓富康李康春马骁飞陈彪刘宇恒黄旖瑶

Owner GUANGXI UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com