Novel dry coal powder entrained-flow bed deslagging system

A technology of dry coal powder and entrained bed, which is applied in the field of entrained bed gasification, can solve the problems of poor temperature control of the gasifier, too fast change, unstable coal properties, agglomeration and fine slag slag blocking, etc. Long-term stable operation, easy operation, and the effect of removing slag from the locking bucket system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

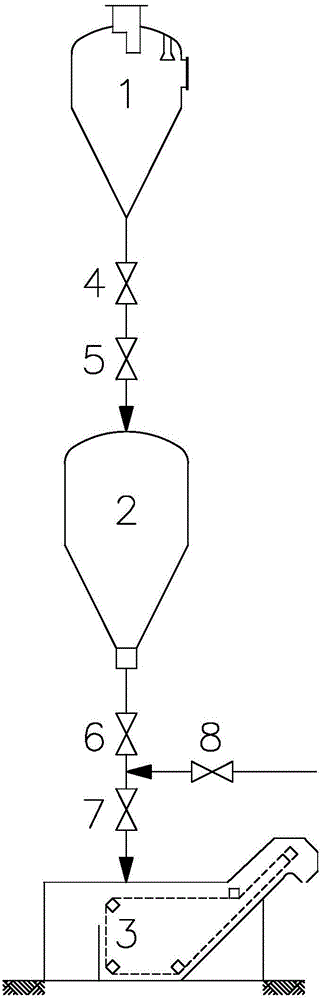

[0020] like figure 1 As shown, a new dry coal powder entrained bed slag discharge system is responsible for cooling, granulating and discharging the liquid slag flowing out of the slag outlet. It includes a slag collector 1, a slag lock hopper 2 connected with a pressure circulation pump at the outlet of the slag collector 1, and a slag dewatering tank 3 with a chain slag extractor at the outlet of the slag lock hopper 2. The slag collector 1 receives the slag particles generated in the slag pool and the slag breaker, and the connecting pipeline between the slag collector 1 and the slag lock hopper 2 is provided with a first double valve group consisting of a first valve 4 and a second valve 5; The connecting pipeline between the lock hopper 2 and the slag dewatering tank 3 is provided with a second double valve group consisting of the third va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com