Method for manufacturing construction sand by virtue of copper ore dump leaching slag

A technology for heap leaching slag and slag from copper mines, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as high cost, destruction of land, mountains and forests, and achieve the effect of avoiding waste water discharge and overcoming adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

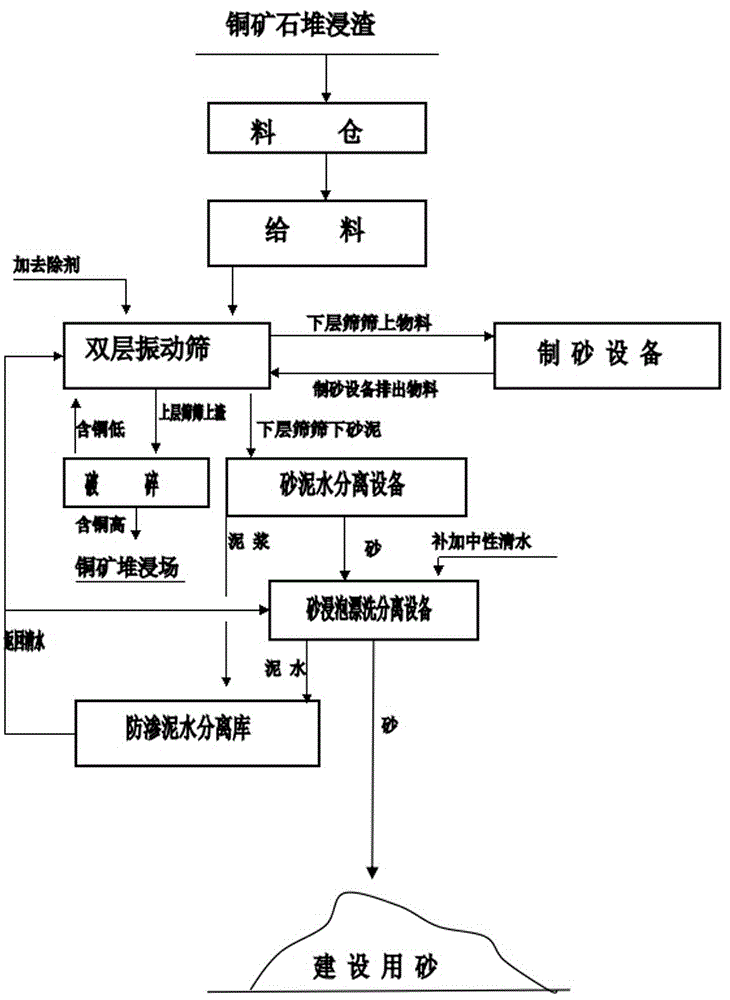

[0020] like figure 1 Shown, a kind of method that utilizes copper ore heap leaching slag to manufacture construction sand, the present invention utilizes copper ore heap leaching slag as sand-making raw material, utilizes screening to control the slag particle size that enters sand-making process, adds and removes in sand-making process The residual trace sulfuric acid and copper sulfate in the copper ore heap leaching slag are removed by the agent, and the deslimed sand in the sand making process is soaked and rinsed in neutral water to produce construction sand after desliming.

[0021] In the present invention, the copper ore heap leaching slag is screened, the slag under the screen enters the sand making process, the slag on the sieve with high copper grade is broken and returned to the heap leaching, and the slag on the screen with low copper grade is broken and returned to the sand making process, wherein The high grade of the copper content is 0.1%-0.5%; the low grade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com