Processing technology of power battery post body

A processing technology and power battery technology, which is applied in the direction of batteries, battery pack parts, battery boxes/coatings, etc., can solve the problems of large material loss, increased internal resistance of connections, and oxide films on riveting parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

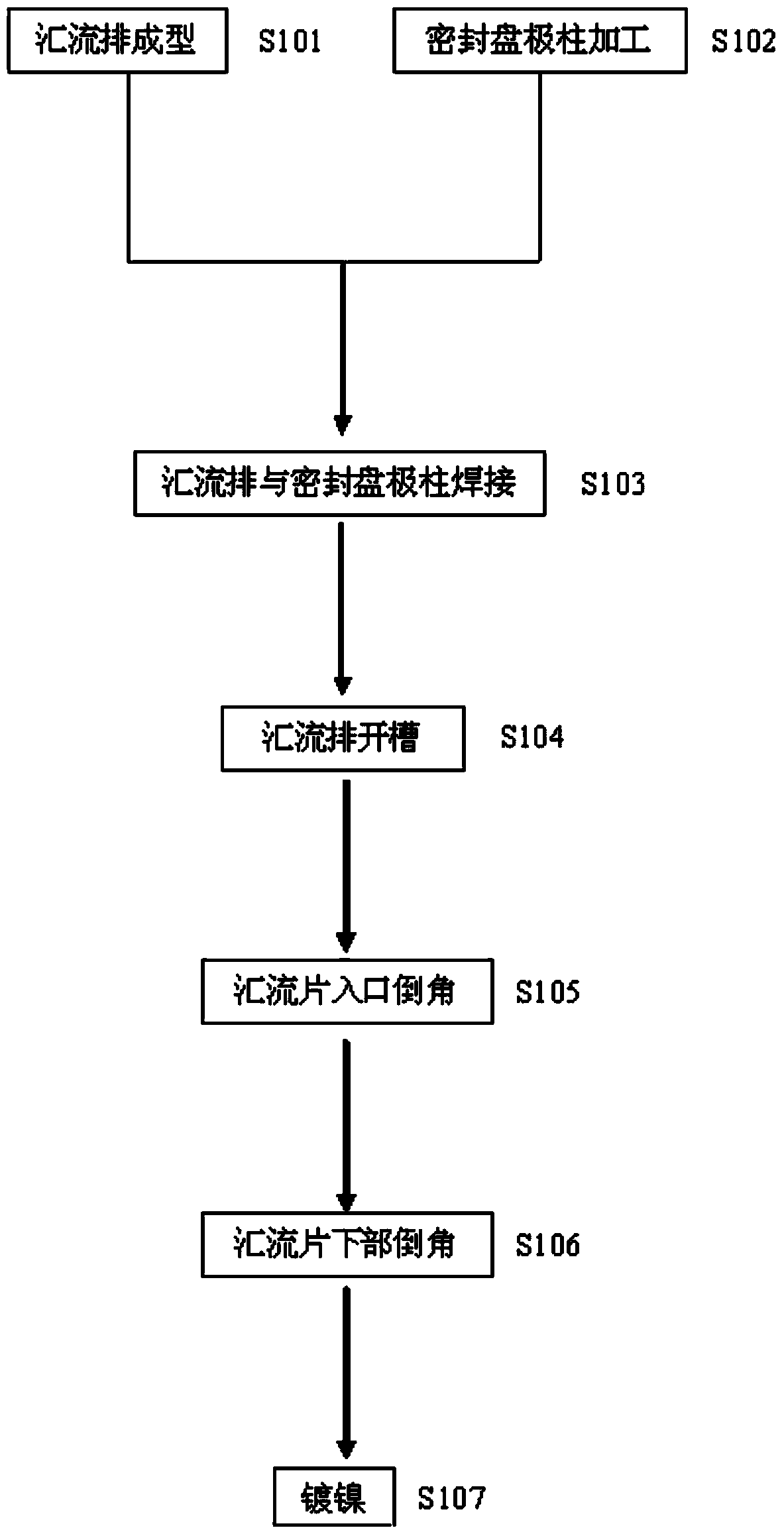

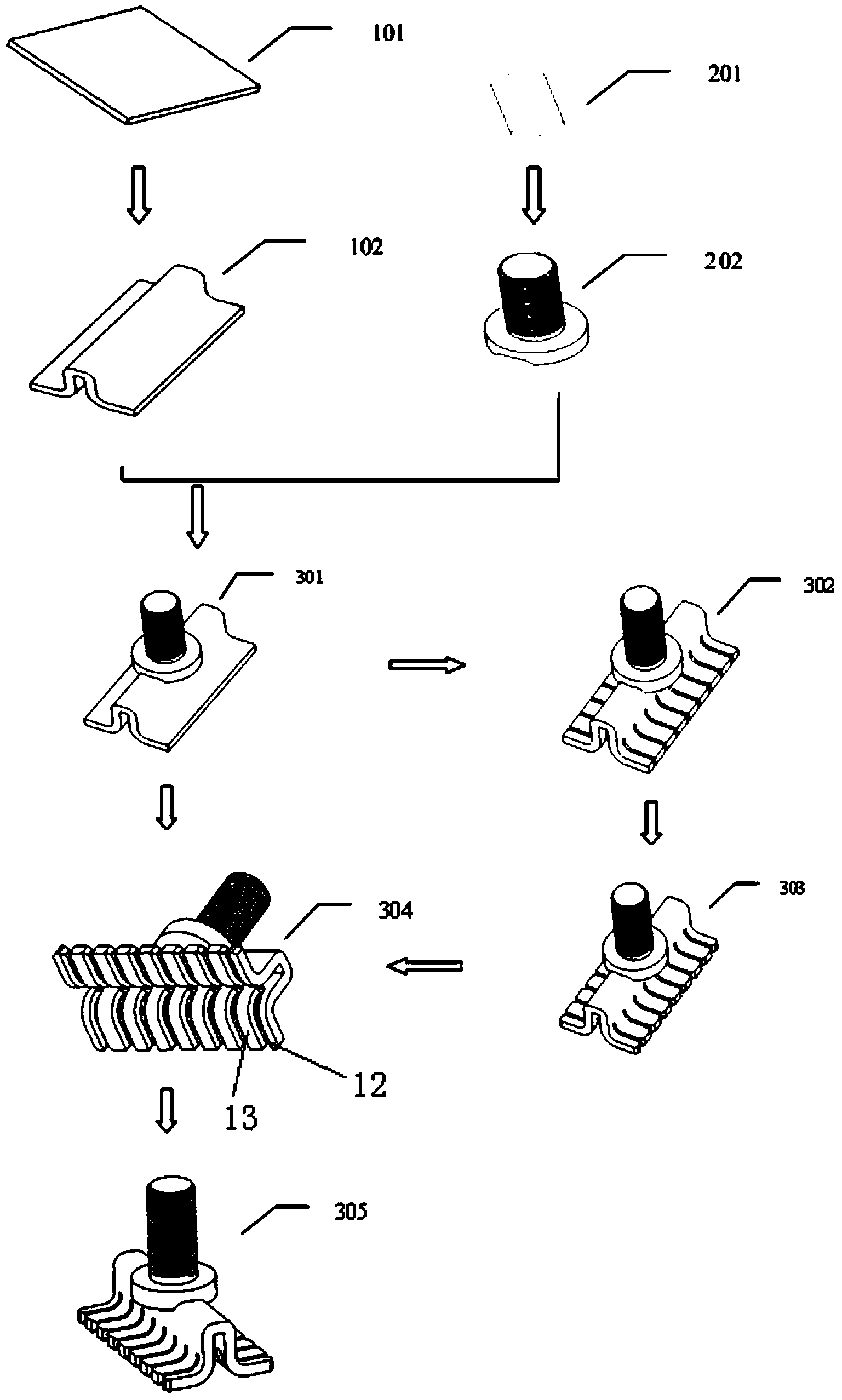

[0024] Such as figure 1 , 2 As shown, the manufacturing method of the power battery pole body in this embodiment includes the following steps:

[0025] Step S101, forming the busbar:

[0026] Utilize mold to make material 101 as figure 2 The shape of the bus bar semi-finished product 102 shown in , the bus bar is formed by stamping or casting.

[0027] Step S102, processing the sealing disc pole:

[0028] Using machining methods to process raw materials 201 such as figure 2 The sealed disc pole semi-finished product 202 shown in .

[0029] Step S103, welding the sealing plate between the bus bar and the sealing plate pole:

[0030] The semi-finished busbar 102 and the semi-finished sealing disc pole 202 are welded together by high-frequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com