Solar cell slice and fabrication method thereof

A technology of solar cells and back electric field, applied in the field of solar cells, can solve the problems that the fine density of the grid lines of the silver seed layer is not easy to meet the design requirements, the photoelectric conversion efficiency of the cells is decreased, the short-circuit current of the cells is decreased, etc., and the short-circuit current and the filling factor can be achieved. Increase, photoelectric conversion efficiency improvement, series resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

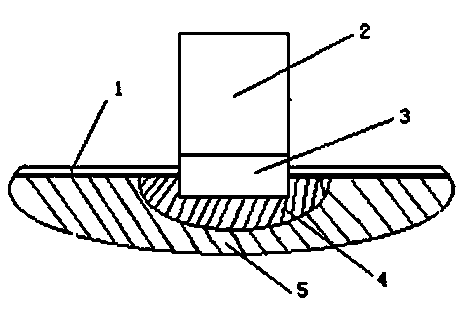

[0029] (1) The specifications of the polysilicon wafer used are: 156×156mm. The thickness is 200 μm (before etching), and the thickness before printing is 180 μm. Texturize the silicon wafer, make PN junction, and coat silicon nitride anti-reflection film by PECVD method. First use screen printing back silver paste (PV505 silver paste from Dupont Company), dry it, and print the back field aluminum paste (Taiwan Shuohe Technology 108C aluminum paste) on the remaining part of the back light surface after printing the back silver paste. After drying, After sintering in a tunnel furnace, a silicon substrate sheet with a silver back electrode and an aluminum back field is obtained.

[0030] as attached figure 1 shown.

[0031] (2) Preparation of heavily doped selective emitter region 4

[0032] The front electrode is designed to include three main grids, and a layer of phosphoric acid solution with a concentration of 2.0wt% is spin-coated on the silicon base sheet 5 (the front ...

Embodiment 2

[0040] Solar cell sample S2 was prepared in the same manner as in Example 1, except that the evaporation time in step (3) was 8 minutes, and the obtained sub-grid metal titanium layer had a height of 0.20-0.40 μm and a width of 8.0- 10 μm. The total height of the sub-grid lines of the front electrodes obtained from the test is 9.0-12 μm, and the total width is 18-23 μm.

Embodiment 3

[0042] Solar cell sample S3 was prepared by the same method and steps as in Example 1, except that the evaporation time in step (3) was 30 minutes, and the height of the titanium layer of the auxiliary grid line was 1.4-1.6 μm, and the width was 15-15 μm. 18 μm. The total height of the sub-grid lines of the front electrodes obtained from the test is 12-15 μm, and the total width is 25-30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com