Analyzer for gas dissolved in mobile type insulating oil and detection method of gas dissolved in mobile type insulating oil

A dissolved gas analysis and detection method technology, applied in the direction of analysis materials, instruments, measuring devices, etc., can solve the problems of low automation, complex hardware structure, and multiple gas sources, so as to improve the automation level, simplify the system structure, and ensure reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

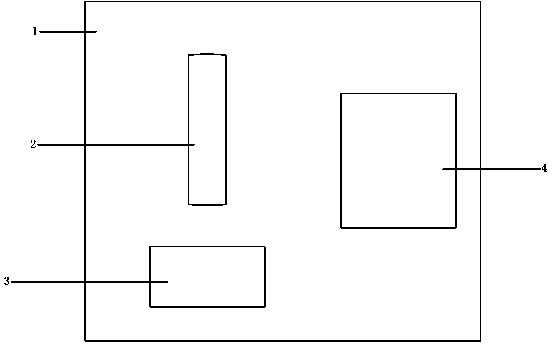

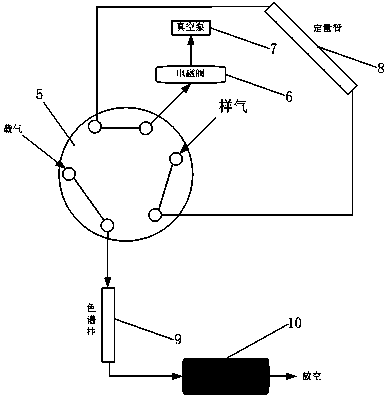

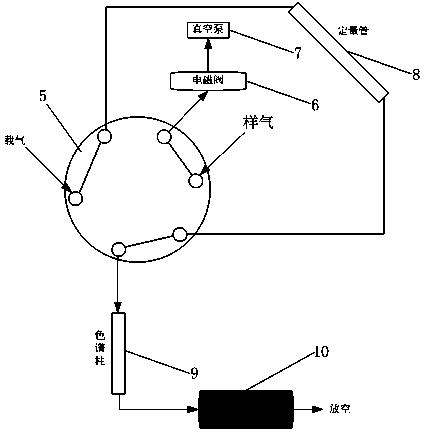

[0020] like figure 1 As shown, the mobile dissolved gas analyzer in insulating oil and the detection method of the present invention include a box body 1, an automatic sampling mechanism 3, a sample gas separation mechanism 4 and a semiconductor detection mechanism 2 are arranged in the box body 1, and the automatic sampling mechanism Sample mechanism 3 includes six-way valve 5, electromagnetic valve 6, vacuum pump 7, quantitative tube 8, mixed gas separation mechanism mainly includes chromatographic column 9 and auxiliary pipeline and insulation cotton, mixed gas detection mechanism mainly includes semiconductor detector 10 and auxiliary pipeline.

[0021] like figure 2 As shown, in the baseline state, the carrier gas directly enters the chromatographic column 9 through the six-way valve 5, and the other end of the chromatographic column 9 is connected to the input end of the semiconductor detector 10 through an auxiliary pipeline, and the output end of the semiconductor de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com