Method for measuring trace elements such as arsenic and antimony in industrial lead bullion according to atomic fluorescence spectrometry

A technique of atomic fluorescence spectroscopy and trace elements, which is applied in the field of analysis of trace elements in high-purity metals, can solve the problems that have not been reported in the application, and achieve the effect of less damage to the detection personnel, high degree of automation, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

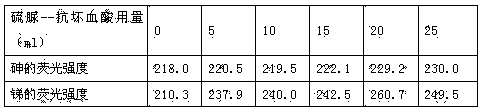

[0027] The implementation process of the present invention is illustrated below with a specific test process.

[0028] 1. Drug preparation:

[0029] 1.1. Hydrochloric acid: ρ1.19g / mL, superior grade.

[0030] 1.2. Nitric acid: ρ1.42g / mL, superior grade.

[0031] 1.3, 5% hydrochloric acid: The preparation method is to pipette 5mL of the above-mentioned high-grade pure hydrochloric acid into a 100mL beaker with a small amount of water, dilute to the mark and mix well.

[0032] 1.4. Carrier solution: In a 500mL beaker, add 300mL of water, then add 50mL of the above-mentioned high-grade pure hydrochloric acid, dilute to the mark, mix well, and cool to room temperature.

[0033] 1.5. Thiourea-ascorbic acid solution (50g / L-50g / L): The preparation method is to weigh 5g of superior pure thiourea and 5g of superior pure ascorbic acid respectively, dissolve them in a 100mL beaker, mix well after dissolving completely, and now Ready to use.

[0034] 1.6. Potassium borohydride solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com