An injection type snow blowing cart

A technology of snow blower and air jet, which is applied in the direction of snow surface cleaning, cleaning methods, construction, etc. It can solve the problems of hardening, inability to achieve better snow removal effect, and inability to achieve snow removal work well, so as to achieve effective cleaning and realize snow blowing The effect of no dead angle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

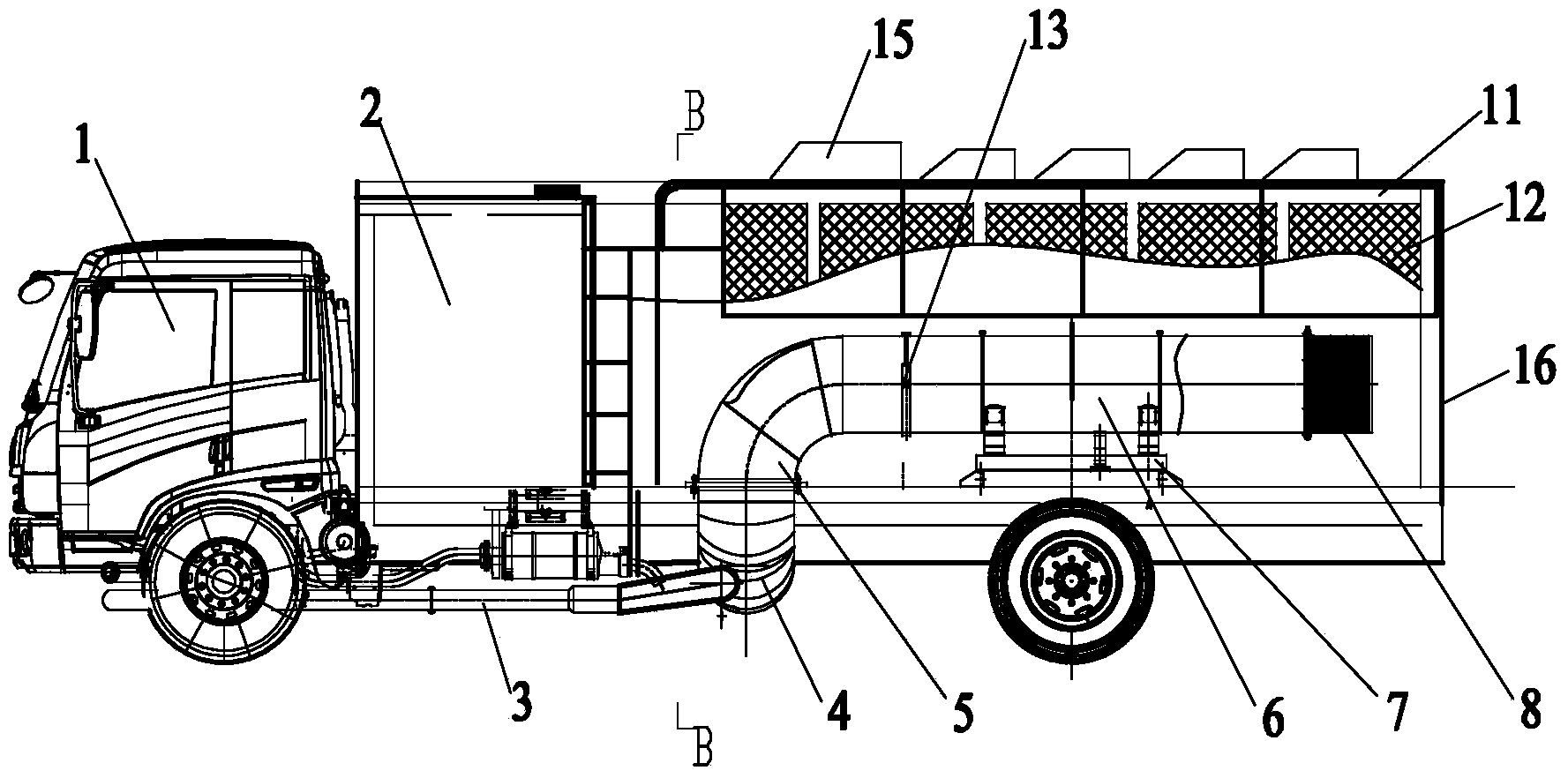

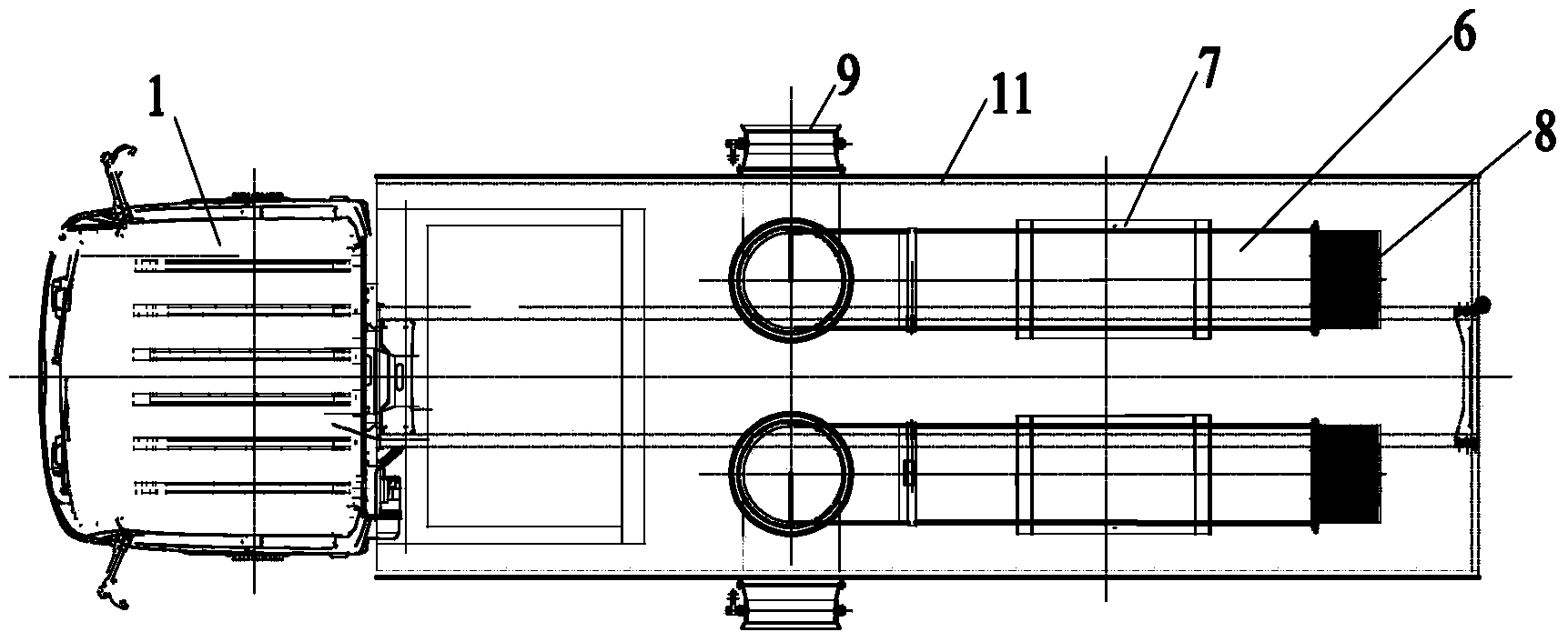

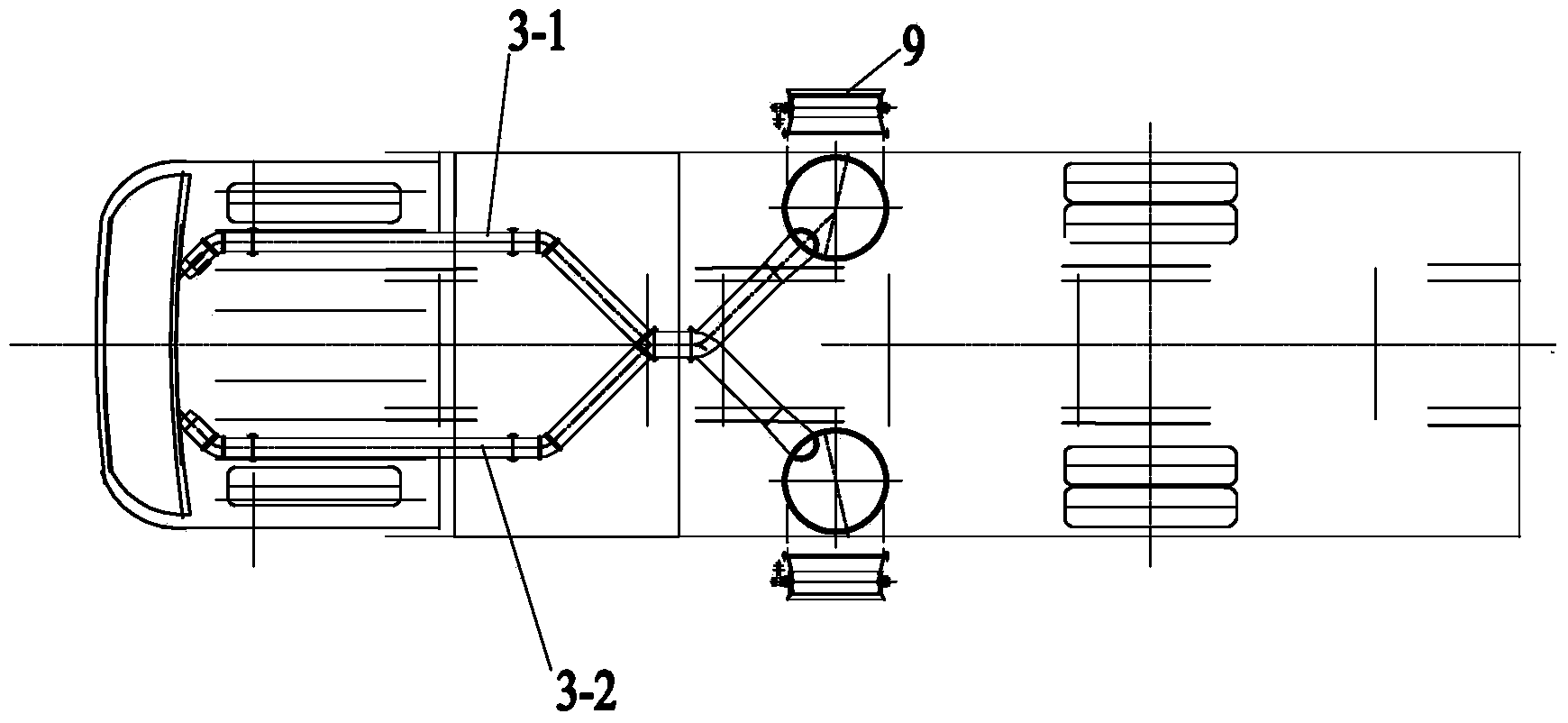

[0023] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0024] Figures 1~8 Among them, including the second-class chassis 1, fuel tank 2, front hot gas nozzle 3, first front hot gas nozzle 3-1, second front hot gas nozzle 3-2, snow blowing tail pipe 4, hot gas tail pipe 5, turbo jet Engine 6, shock-absorbing platform 7, bottom frame 7-1, seat plate 7-2, first rubber shock absorber 7-3, connecting seat 7-4, connecting plate 7-5, axle seat 7-6, first rubber shock absorber 7-3 Two rubber shock absorbers 7-7, cross shaft seat 7-8, limit sleeve 7-9, intake filter 8, nozzle 9, nozzle seat 9-1, nozzle mask 9-2, adjusting arm 9-3, Adjusting slide 9-4, driving oil cylinder 10, air intake compartment 11, air intake filter 12, connection buckle 13, deflector 14, air deflector 15, rear box panel 16, etc.

[0025] like Figures 1~8 As shown, the present invention is a jet-type snow blower, including a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com