Preparation method of organic water flushed fertilizer

An organic fertilization technology, applied in the field of fertilizer production, can solve the problems that do not belong to, restrict the production of organic fertilization products, and cannot be produced with organic agricultural products, and achieve the effect of comprehensive nutrition, reasonable quantity and improved effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

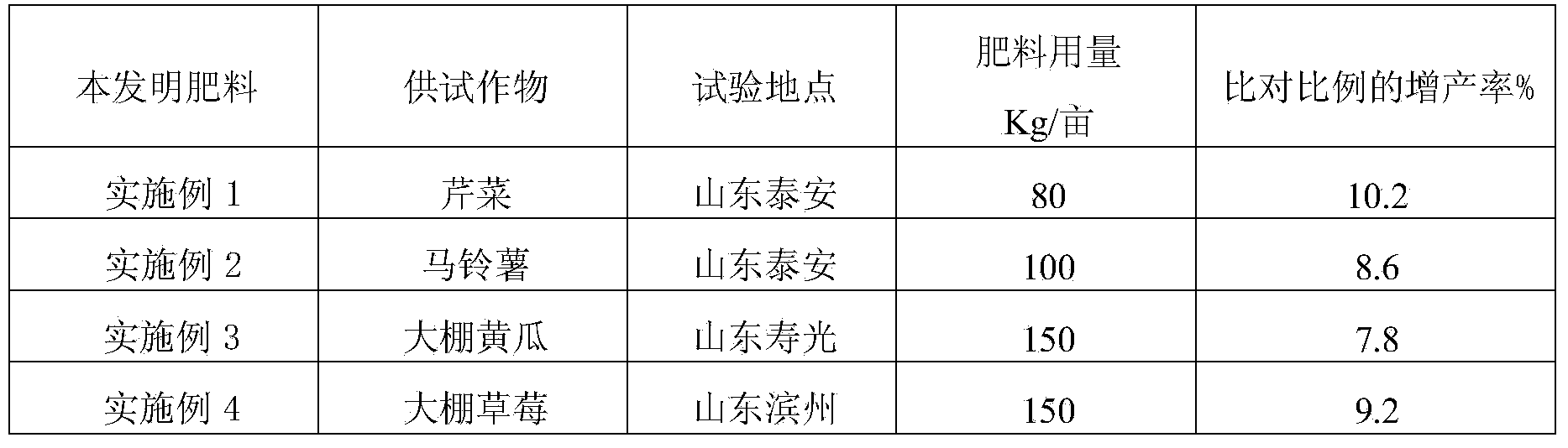

Examples

Embodiment 1

[0049] Embodiment 1: Organic flushing fertilization, the components are as follows:

[0050] 60 kg of protein hydrolyzate, 20 kg of phytic acid hydrolyzate, and 20 kg of plant ash extract.

[0051] The preparation method is as follows:

[0052] (1) Take 300 kg of fresh corn germ oil residue and add it to the container, add 1500 kg of water, adjust the pH value to 8.0, add 0.5 kg of lipase preparation (SUKALip PW12.5), stir for 5 minutes, and place it at 38°C for 48 hours , stirring once every 2 hours during this period, each time for 3 minutes, to obtain lipolysis oil residue; set aside;

[0053] (2) Take 200 kg of lipolytic oil residue prepared in step (1), boil for 15 minutes, adjust the pH value to 7.0 after cooling, add 0.01 kg of neutral protease preparation SUKAPro NEPW50, stir for 4 minutes, and place it at 58°C 2 hours, stirring once every 0.5 hours during the period, 2 minutes each time, spray drying after the end, to obtain protein hydrolyzate; set aside;

[0054]...

Embodiment 2

[0058] Embodiment 2: organic flush fertilization, composition is as follows:

[0059] 25 kg of protein hydrolyzate, 50 kg of phytic acid hydrolyzate, and 25 kg of plant ash extract.

[0060] The preparation method is the same as in Example 1, except that the oil residue is a 1:1 composition of peanut oil residue and rapeseed oil residue.

[0061] The fertilizer in this embodiment is suitable for crops that require more phosphorus nutrition, such as root and tuber crops, sugar crops, and leguminous crops.

Embodiment 3

[0062] Embodiment 3: organic flush fertilization, composition is as follows:

[0063] 30 kg of protein hydrolyzate, 35 kg of phytic acid hydrolyzate, and 35 kg of plant ash extract.

[0064] The preparation method is as follows:

[0065] (1) Take 300 kg of fresh soybean oil residue and put it into a container, add 1000 kg of water, adjust the pH value to 7.6, add 1.0 kg of lipase preparation (SUKALip PW10), stir for 5 minutes, and place it at 44°C for 43 hours. Stir once every 2 hours, 3 minutes each time, to obtain lipolysis oil residue; set aside;

[0066] (2) Take 300 kg of lipolysis oil residue prepared in step (1), boil for 10 minutes, adjust the pH value to 7.5 after cooling, add 0.05 kg of neutral protease preparation SUKAPro NE PW50 and NE PW30 in a mass ratio of 1:1 The composition was stirred for 4 minutes, and placed at 53°C for 3 hours, during which it was stirred every 0.5 hours for 2 minutes each time, and spray-dried after the end to obtain a protein hydrolyza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com