Antirust film of door and preparation method of antirust film

A gas-phase rust inhibitor and styrofoam technology, applied in the field of packaging materials, can solve the problems of poor flexibility of the rust-proof film, inability to meet the door rust prevention, poor rust-proof effect, etc. Rust ability and time, the effect of enhancing rust prevention ability and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

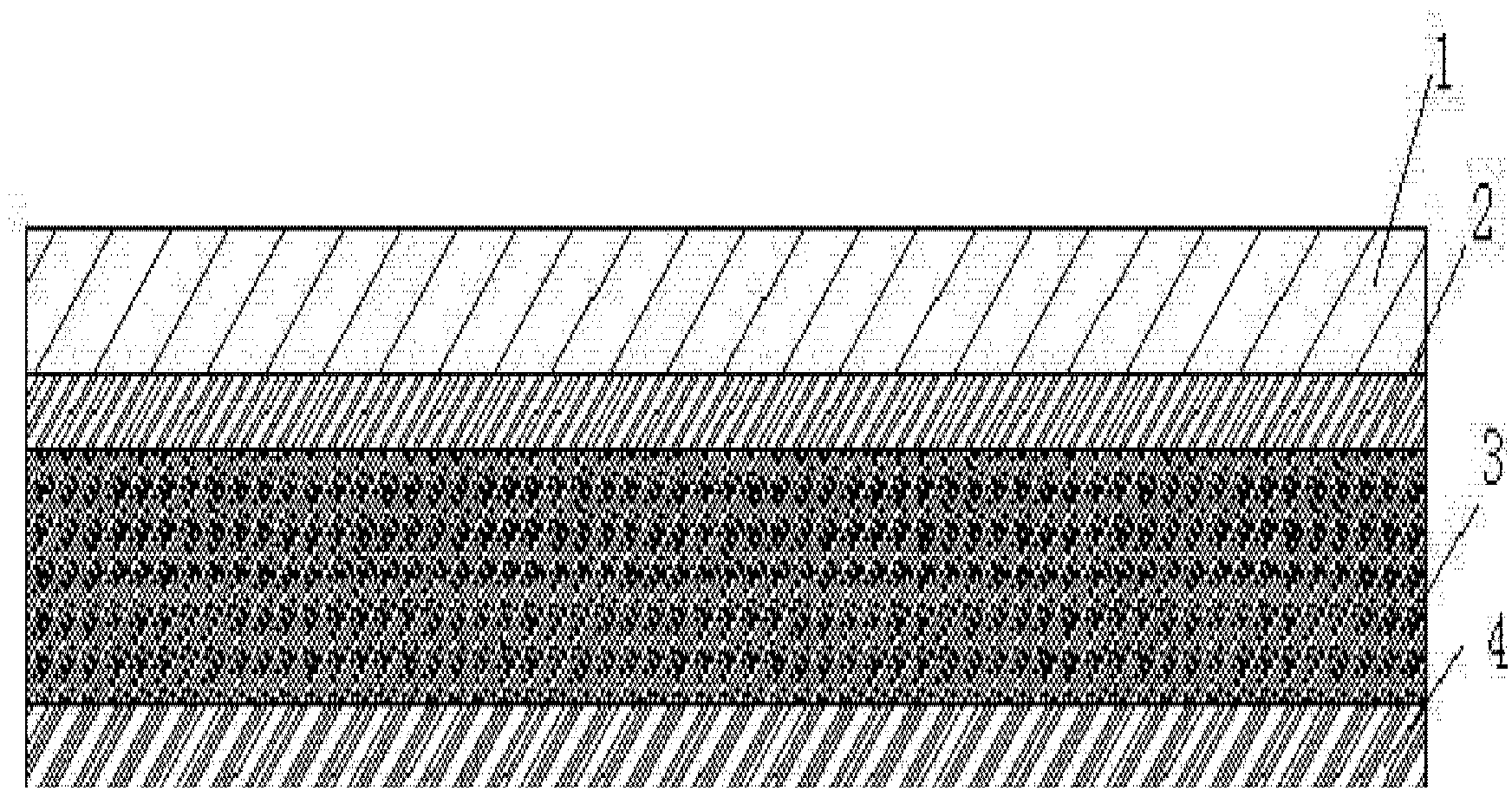

[0028] refer to figure 1 , a kind of anti-rust film suitable for doors, take polypropylene resin pressure-sensitive adhesive, add gas-phase anti-rust agent according to 20% of the weight of the pressure-sensitive adhesive, mix evenly, and set aside, take a nylon film with a thickness of 20 μm, and mix polyurethane Grease foaming glue is evenly coated on one surface with a thickness of about 30 μm. After a little drying, apply a pressure-sensitive adhesive mixed with a gas-phase antirust agent on the surface of the foaming rubber layer with a thickness of about 20 μm. A 50 μm PVC film containing the anti-rust agent is pasted on the surface of the pressure-sensitive adhesive layer and dried at 50-60° C. to obtain the anti-rust film of the present invention.

Embodiment 2-5

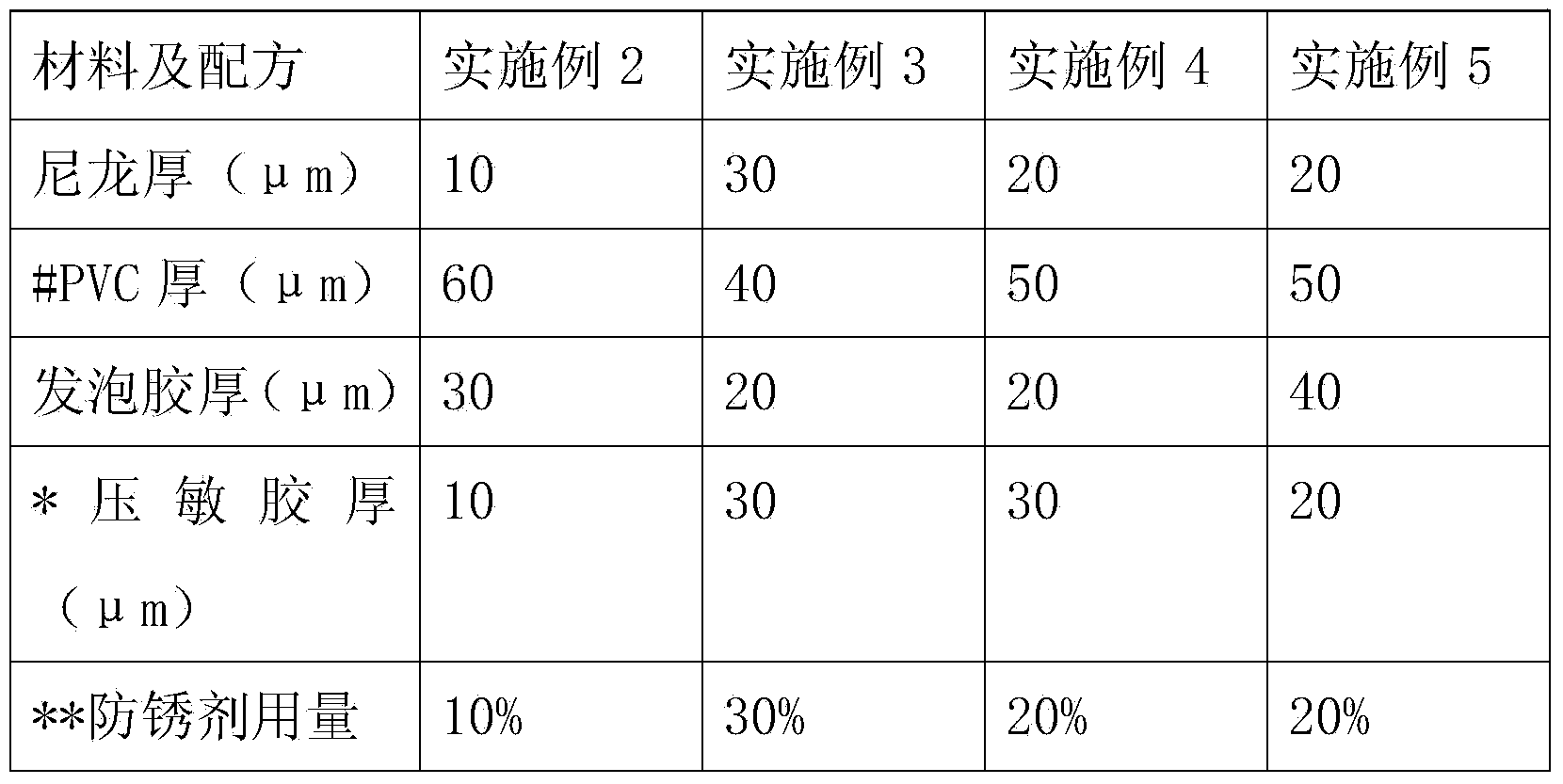

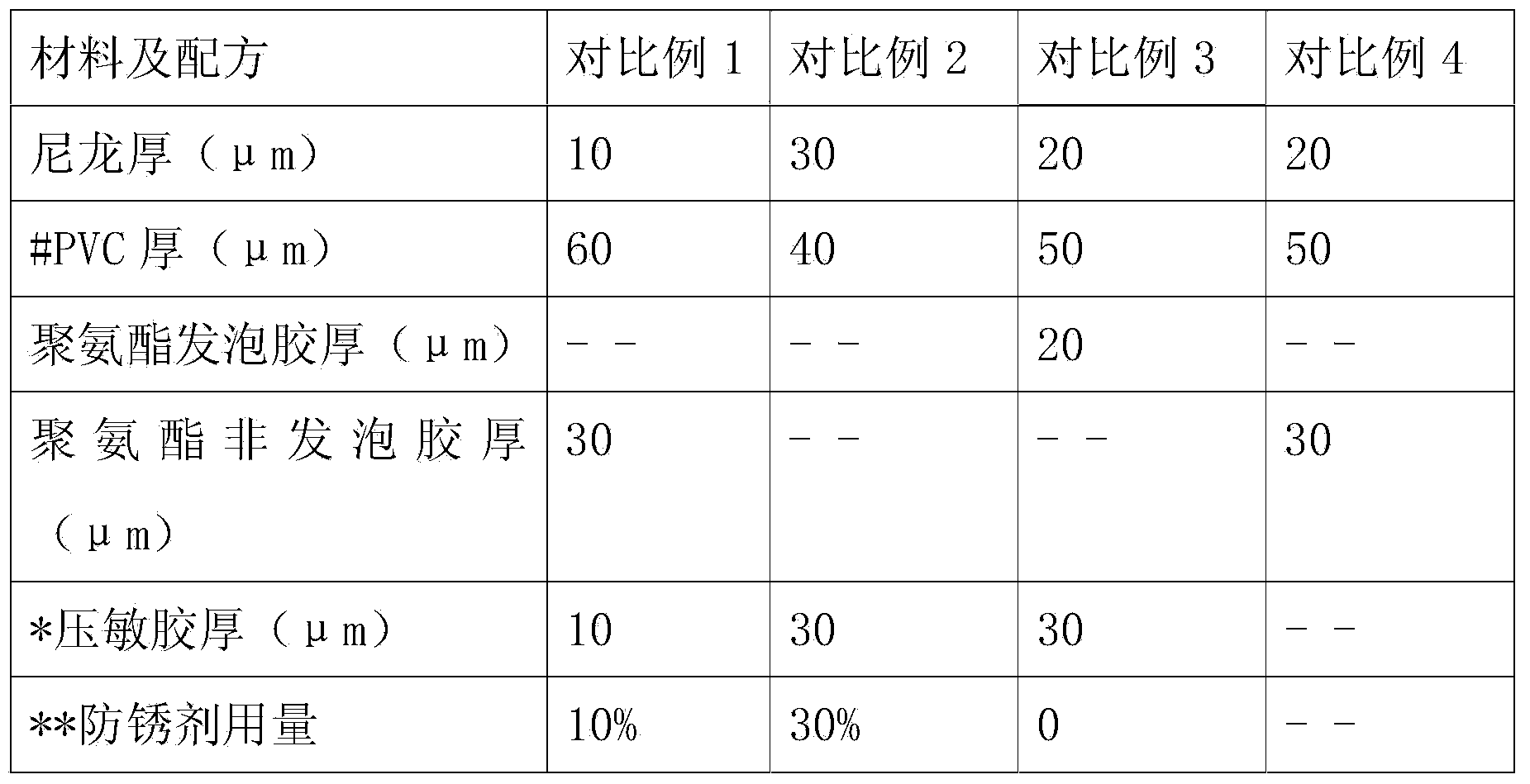

[0030] The antirust film of embodiment 2-5 has identical structure with embodiment 1, and material and formula are shown in table 1 below

[0031] The material and the prescription of the antirust film of table 1 embodiment 2-5

[0032]

[0033] In the table, #PVC film containing vapor phase antirust agent is purchased through commercial channels, * is polypropylene resin pressure-sensitive adhesive, and ** dosage is the percentage of pressure-sensitive adhesive weight.

[0034] Preparation process: prepared according to the method of Example 1.

Embodiment 6

[0041] Embodiment 6 effect test

[0042] Paste the rust preventives of Examples 1-5 and Comparative Examples 1-4 on the steel plate surface of the fire door, and carry out the salt spray test according to the GB / T10125-1997 standard.

[0043] Test Conditions:

[0044] Settling salt solution concentration: 50±5g / L NaCl

[0045] Chamber temperature: 35±2°C

[0046] Salt mist deposition rate: (1.0-2.0)ml / 80cm 2 .h

[0047] Precipitation salt solution pH: (35±2°C)6.5-7.2

[0048] Exposure time: 500 hours

[0049] The test results are shown in Table 3

[0050] Table 3 embodiment 1-5 and comparative example 1-4 performance test result

[0051]

[0052] The results in the table show that the anti-rust film with pressure-sensitive adhesive layer is in close contact with the steel plate, without peeling and blistering, and the anti-rust film without pressure-sensitive adhesive layer is easy to fall off and foam, and no polyurethane foam is used. And the anti-rust film without ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com