Cold press for woodware splicing

A cold press and wood product technology, which is applied in the field of solid wood processing, can solve problems such as difficulty in controlling the surface flatness and warpage of wood boards, uneven product surfaces, and large anisotropy of blocks, so as to reduce the labor intensity of workers, Good ventilation performance and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

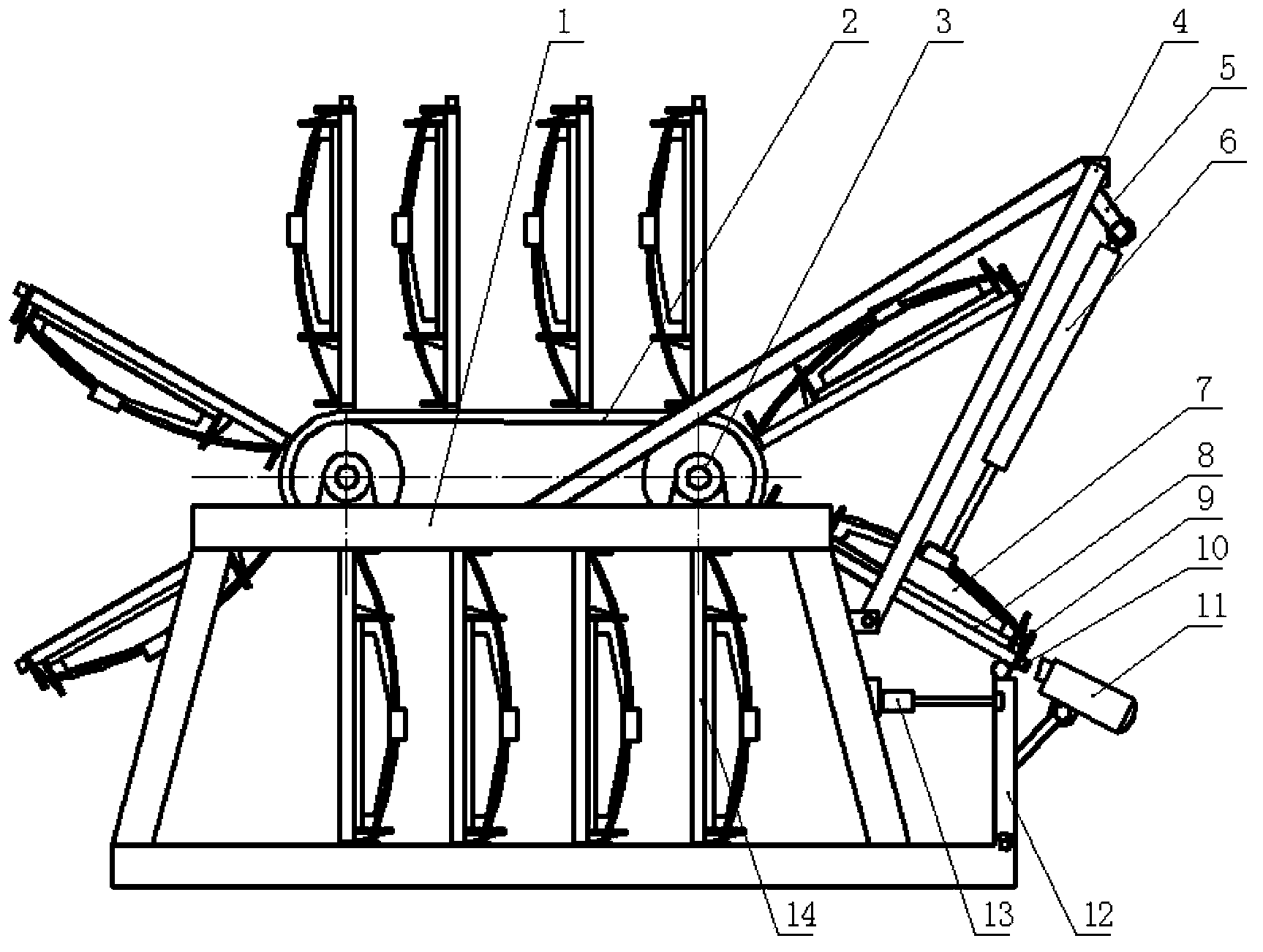

[0028] A cold press machine for splicing wood products, including a frame 1, a support roller shaft 3, a transmission hinge 2, and a cold press plate 14. There are two support rollers installed at the same axial horizontal interval on the frame, and a metal transmission hinge is fitted on the two support rollers, and one of the support rollers is driven by a motor to drive the other through the transmission hinge. The supporting rollers rotate synchronously, and the transmission hinge shown in the accompanying drawings of this embodiment rotates counterclockwise; the outer periphery of the transmission hinge is evenly spaced and fixed with a plurality of cold pressing plates, as shown in the accompany...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com