Tool sharpener

A knife sharpening machine and knife sharpening stand technology, which is applied in the direction of grinding workpiece brackets, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of consistency and manufacturing efficiency, and achieve small assembly errors and consistent molding Good performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

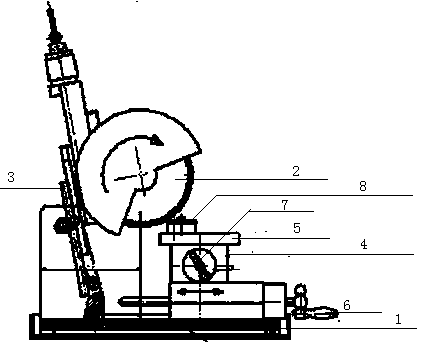

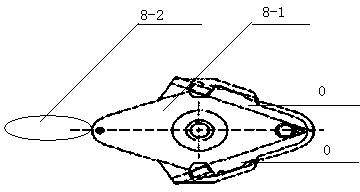

[0019] Such as figure 1 As shown, a knife sharpening machine includes a chassis 1, a sharpening wheel 2, a grinding wheel frame 3, and a knife sharpening frame assembly. The grinding wheel frame 3 is fixed to the chassis 1 through a hinge, and the grinding wheel frame 3 is provided with a slot , the sharpening wheel 2 is fixed on the grinding wheel frame 3 along the slot, and the sharpening frame assembly includes a bracket 4, a rotating shaft frame 5, and an in-out knife adjustment handle 6 and a positioning adjustment handle 7 for adjusting the position of the bracket 4. The sharpening frame assembly also includes a rotary sharpening frame mold 8, and the rotary sharpening frame mold 8 includes a diamond-shaped clamp body 8-1. Rhombus clamp body 8-1 tail end is also fixed with handle 8-2, as figure 2 shown in . Fix the two blades 0 respectively on the adjacent sides of the rhombic fixture body 8-1, and fix and tighten them through bolts and screw holes.

[0020] Adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com