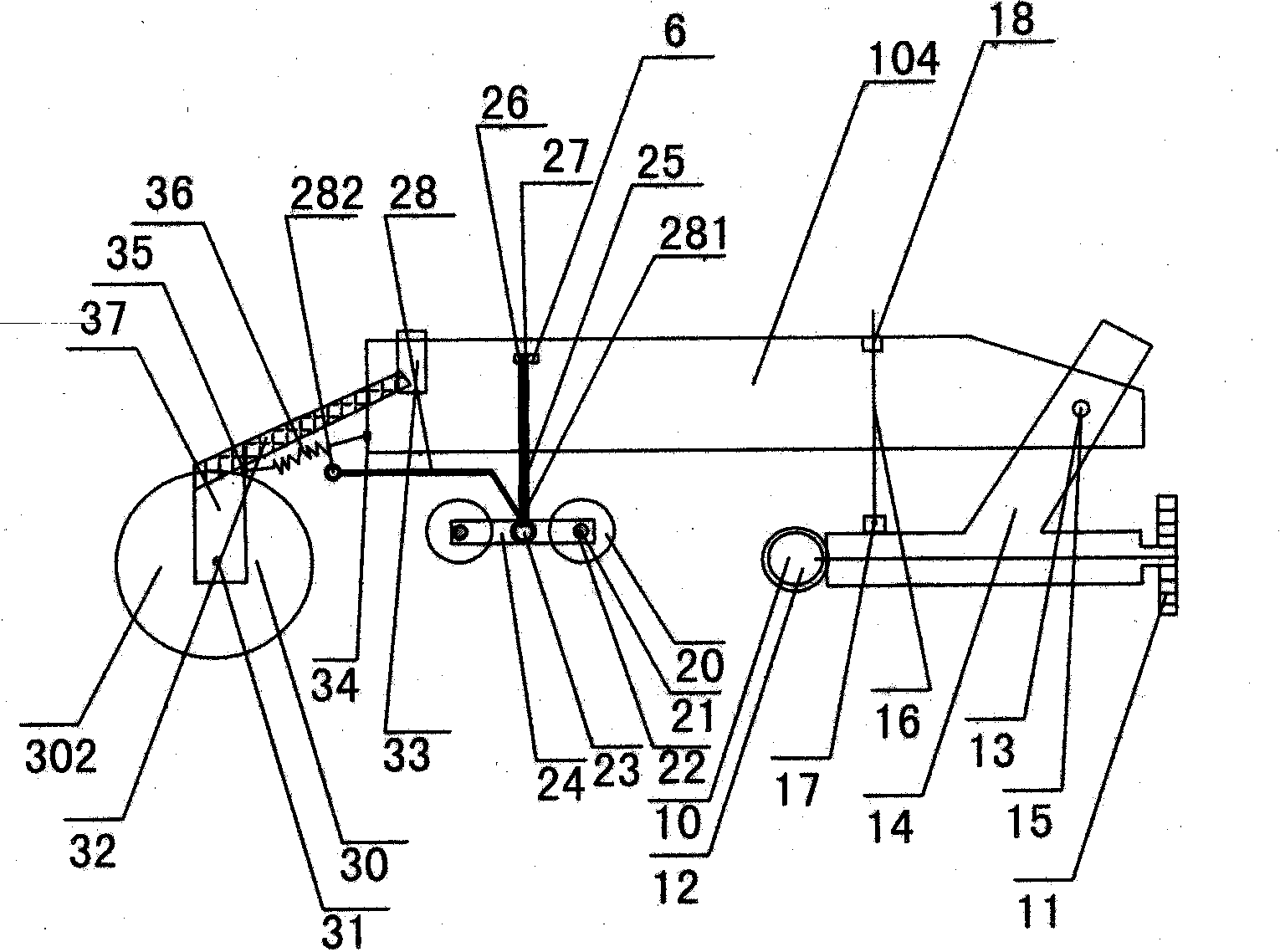

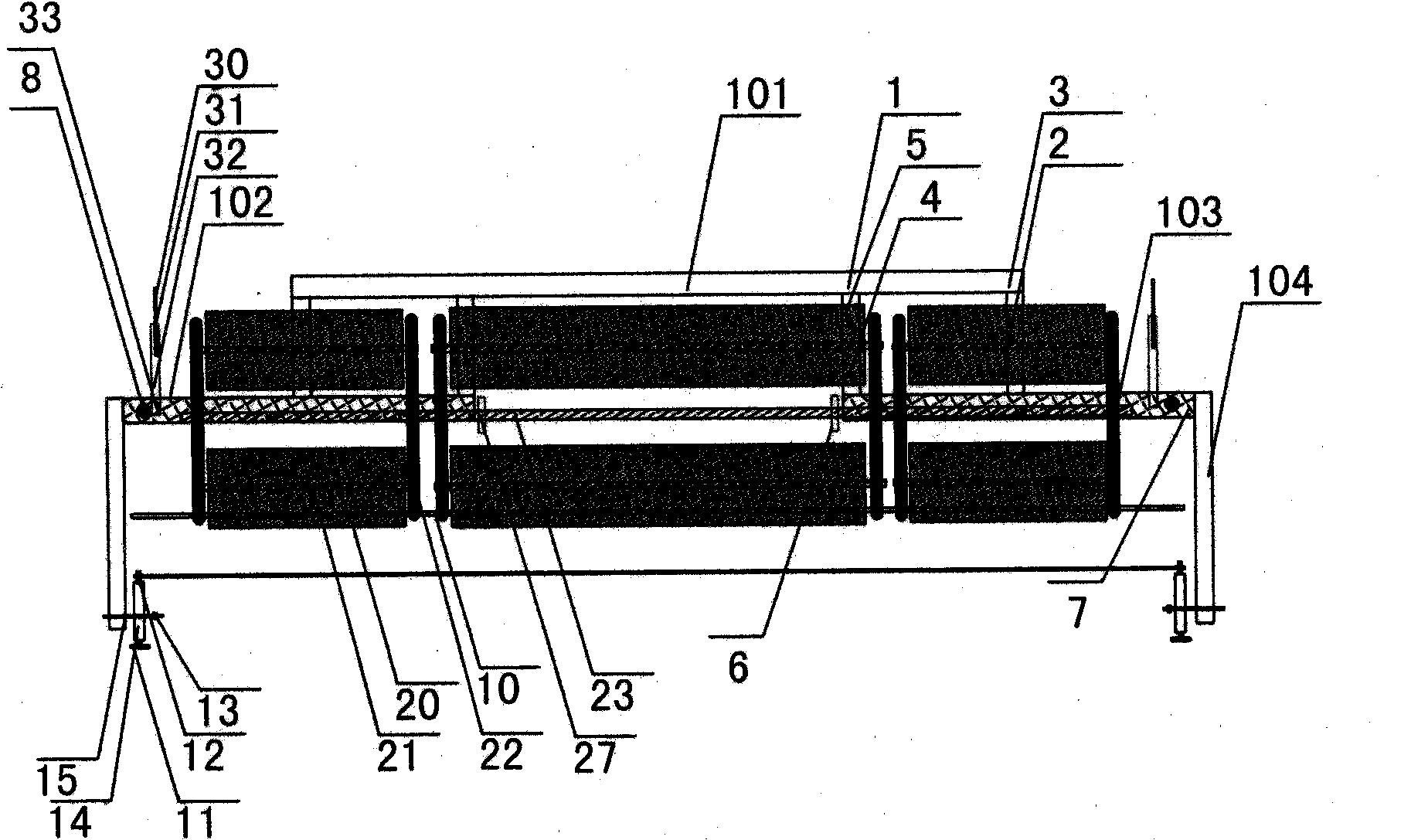

All-in-one film mulching and rice transplanting machine with film cutting knife assembly

A technology of film cutting knife and all-in-one machine, which is applied in planting methods, transplanting machinery, plant protection covers, etc., and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

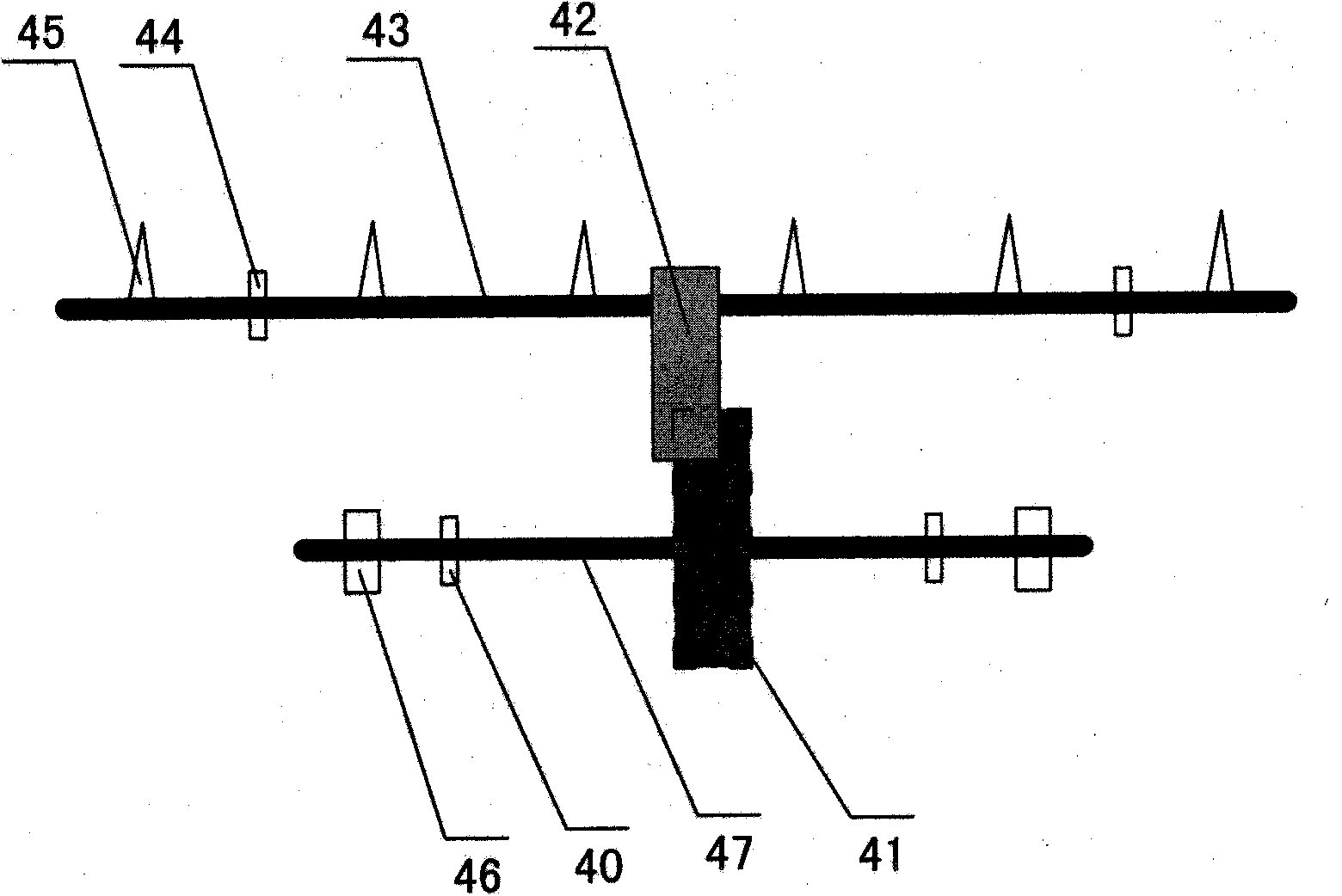

[0057] In this film cutter combination case 1, the power shaft 47 of the rice transplanter is installed in the power bearing group 46 of the rice transplanter.

[0058] The rice transplanter power shaft 47 drives the rice transplanter power output retainer 41 to rotate clockwise. Every time the rice transplanter power shaft 39 rotates 180 degrees, the rice transplanter power output retainer 41 contacts the rice transplanter power receiving retainer 42 once, that is, the rice transplanter power shaft 47 rotates half a circle, the combined carrying beam 43 of the film cutting knife is lowered once, and the film cutting knife 45 is driven to cut the plastic film once. The integrated action of transplanting rice seedlings.

[0059] Rice transplanter power output retainer 41 is set as bilateral symmetry on rice transplanter power shaft 47, to ensure that every half turn of rice transplanter power shaft 47, allow film cutting knife combined carrying beam 43 to explore once, that is,...

Embodiment 2

[0065] Example 2 of film cutter combination: a case of a model that transmits power through gear engagement

[0066] The rice transplanter power shaft 47 drives the rice transplanter power output retaining piece 41 to rotate clockwise. Every time the rice transplanter power shaft 47 rotates 180 degrees, the rice transplanter power output retainer 41 contacts the rice transplanter power receiving retainer 42 once, that is, the rice transplanter power shaft 47 rotates half a circle, the combined carrying beam 43 of the film cutting knife is lowered once, and the film cutting knife 45 is driven to cut the plastic film once. After cutting the film, the seedling claws of the rice transplanter can be transplanted at the incision left by the film cutting knife 45, and the film-covered rice transplanting is completed. integrated action.

[0067] Rice transplanter power output retainer 41 is set as bilateral symmetry on rice transplanter power shaft 47, to ensure that every half turn o...

Embodiment 3

[0074] The rice transplanter power shaft fixed bearing 53 is fixed on the film laminating machine with the mulch shaft by the rice transplanter power receiving shaft 52 and the attached rice transplanter power output catch 41 and the rice transplanter power receiving shaft 52 etc.

[0075] At the same time as the rice transplanter is transplanting, the internal gear of the rice transplanter power gearbox 50 transmits the power to the rice transplanter power output gear 48, and the rice transplanter power output gear 48 transmits the power to the rice transplanter through the rice transplanter power transmission chain 49. On the power receiving gear 51, because the rice transplanter rice transplanting power receiving gear 51 and the rice transplanter power receiving shaft 52 are fixed together, the rice transplanter rice transplanting power gear box 50 internal gear just transmits power to the rice transplanter power receiving shaft 52 like this.

[0076] When the power receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com