Method for the production of an all-solid battery

一种制作方法、固态电解质的技术,应用在二次电池制造、电池电极、二次电池等方向,能够解决难以制作全固态电池或微电池等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

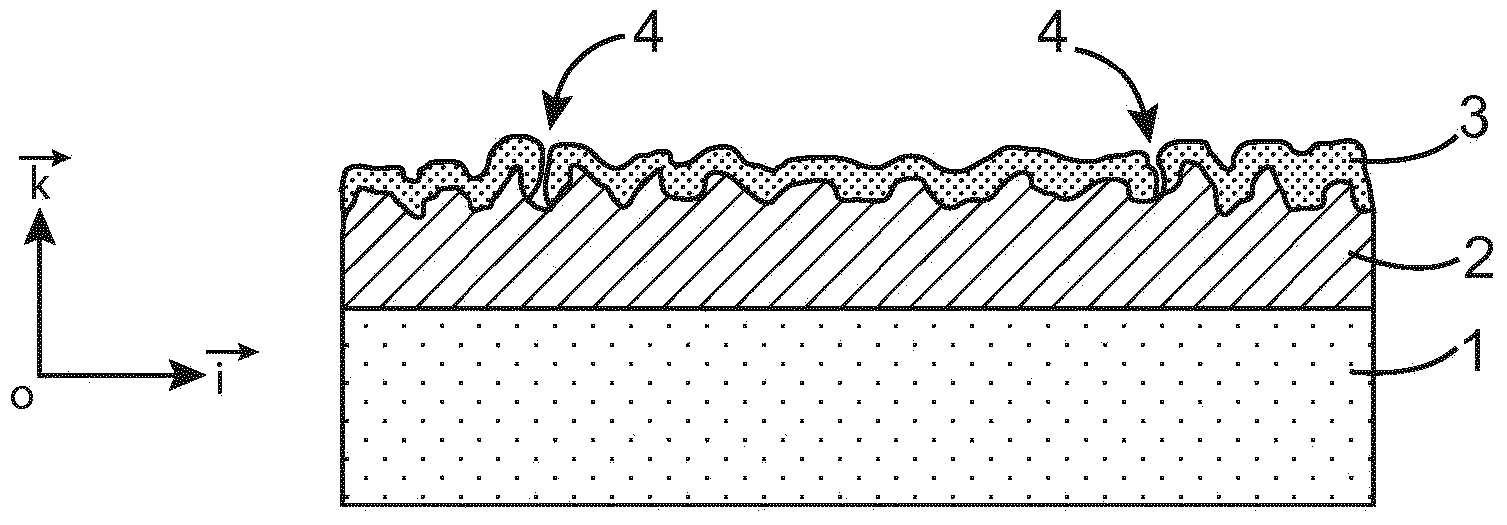

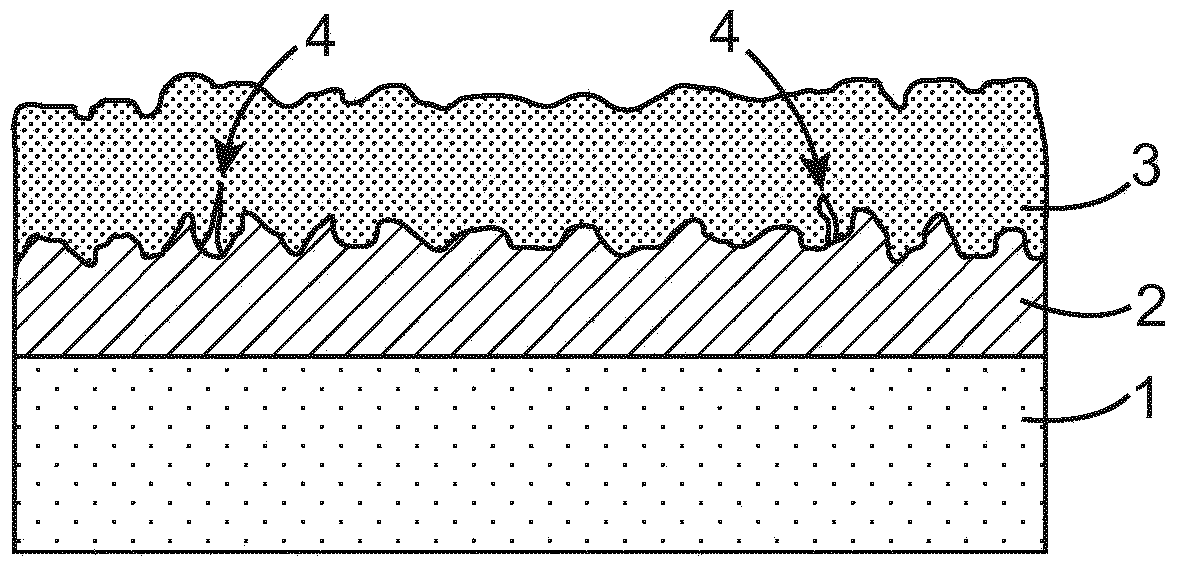

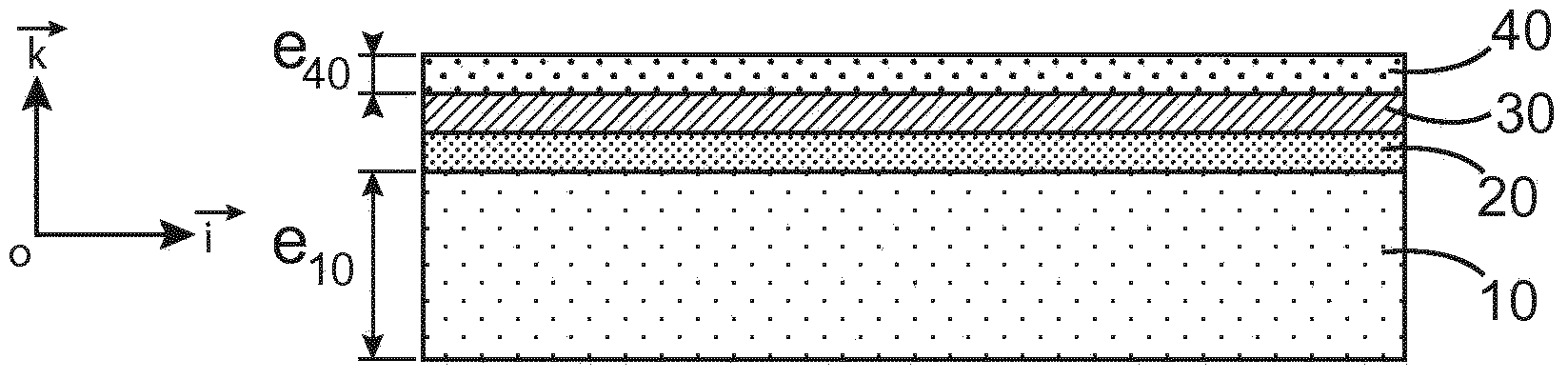

[0051] Several methods of making all-solid-state batteries or micro-batteries are shown below.

[0052] The first fabrication method may consist of a first step comprising the preparation of a substrate made of active material or capable of forming electrodes, which substrate is to be used as a support for an electrochemical cell for the fabrication of an all-solid-state battery. An electrochemical cell includes at least one anode and at least one cathode separated by an electrolyte. Part of the substrate will be used as an electrode of the electrochemical cell.

[0053] The substrate or support 10 is produced from an active material, ie so that at least one atom or ion can be inserted into the substrate 10 comprising said material and so that a part of the substrate can be used as an electrode. The structure of the substrate may be deformed to facilitate the insertion of ions or atoms. Atoms or ions can be of the following types: H, Li, Be, Mg, Na, K.

[0054] The substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com