White light sensitivity resin composition and purpose thereof

A resin composition and optical rotation technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of white photoresist yellowing, poor consumer perception, etc., and achieve high adhesion, excellent resolution, good The effect of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

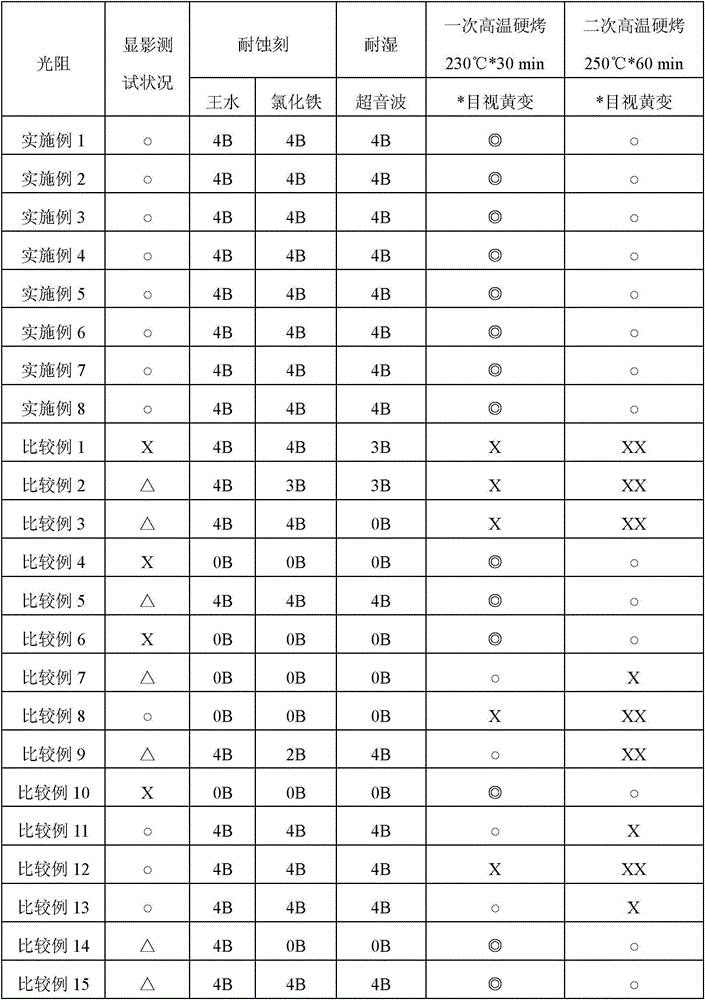

Examples

Embodiment 1

[0029]Uniformly mix 4.86 parts by weight of EL-200 (alkali-soluble resin, manufactured by Yongguang Co.); 3.42 parts by weight of R551 (polymerizable compound having ethylenically unsaturated bonds, manufactured by Nippon Kayaku Co., Ltd.); photoinitiator In the agent, 1-hydroxyl-cyclohexyl-phenyl-ketone (I-184) accounts for 0.72 parts by weight, 2,4,6-trimethylbenzoyl diphenylphosphine oxide (TPO) accounts for 2.88 parts by weight; 1.94 Parts by weight of DPMP (manufactured by Sakai chemical Industry Co., Ltd); 32.56 parts by weight of propylene glycol methyl ether acetate (PGMEA, solvent); 32.50 parts by weight of ethyl lactate (solvent); 21 parts by weight of titanium dioxide (white pigment ); 0.08 parts by weight of I1010 (manufactured by Ciba-BASF); 0.03 parts by weight of S-386 (manufactured by Asahi Whistle Co., Ltd.); and 0.01 parts by weight of HQ (manufactured by Merck, Taiwan). Prepare 100 parts by weight of a white photosensitive resin composition, and then filter ...

Embodiment 2

[0031] The preparation method of the white photosensitive resin composition of Example 2 is substantially the same as that of Example 1, the only difference is that the content of I-184 and TPO constituting the photoinitiator is different. In Example 2, I-184 accounts for 0.97 parts by weight, and TPO accounts for 2.63 parts by weight.

Embodiment 3

[0033] The preparation method of the white photosensitive resin composition of Example 3 is substantially the same as that of Example 1, the only difference is that the content of I-184 and TPO constituting the photoinitiator are different. In Example 3, I-184 accounts for 1.46 parts by weight, and TPO accounts for 2.14 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com