Determination method for content of trace boron in iron oxide powder

A technology of iron oxide powder and determination method, which is applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., and can solve the problems of cumbersome processing, high blank, large colorimetric interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

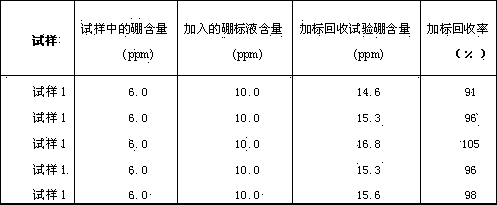

Examples

Embodiment Construction

[0012] The assay method of trace boron content in iron oxide powder of the present invention comprises the steps:

[0013] Step 1. Weigh 1.000g of iron oxide powder and put it into a 150ml quartz beaker, add 10ml of hydrochloric acid and stir evenly. After heating and dissolving at a low temperature of 80-100°C, continue heating until the medium in the quartz beaker is nearly dry, and the quartz beaker is cooled. Then add 15ml of hydrochloric acid and heat the dissolution medium;

[0014] Step 2, transfer the solution in the quartz beaker to a 150ml separating funnel, rinse the quartz beaker with 5ml hydrochloric acid, and merge the washing liquid into the 150ml separating funnel, add 4-methyl-2-pentanone in the separating funnel 50ml, shake vigorously for 1 minute, after static layering, put the water phase in the separatory funnel into a quartz beaker, heat and concentrate on an electric furnace to 13-17ml, remove and cool, then transfer to a 50ml volumetric flask, dilute to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com