Handheld firework mounting machine

A technology of mounting machine and mounting mechanism, which is applied in the direction of weapon types, pyrotechnics, offensive equipment, etc., can solve the problems of difficult product quality assurance, labor and time consumption, low production efficiency, etc., and achieve the goal of reducing production process and production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

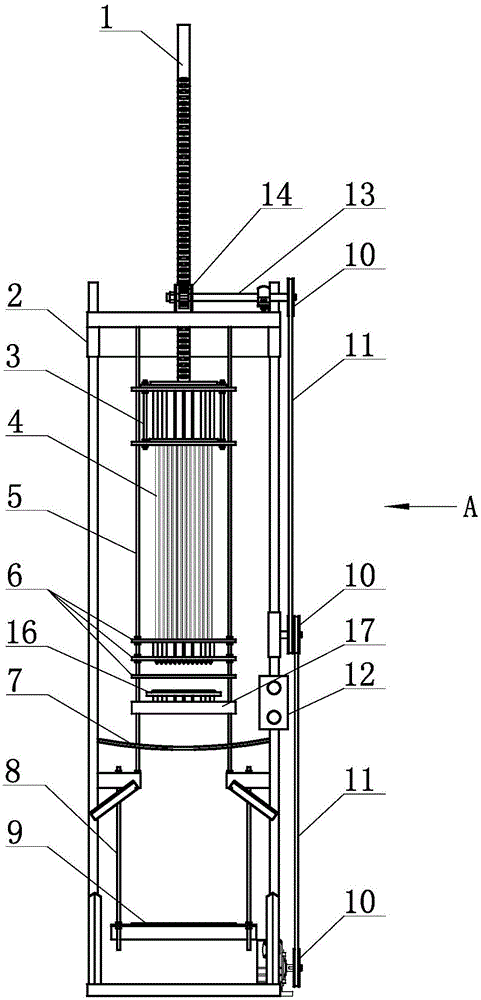

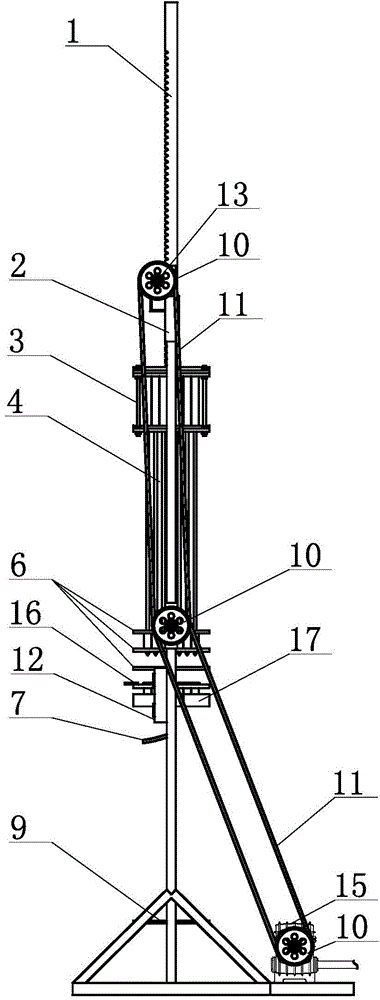

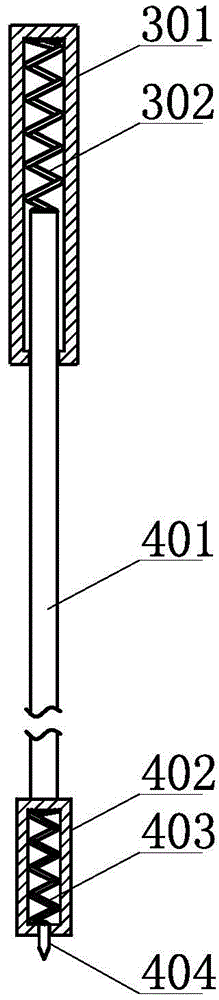

[0039] Below, the present invention will be described in more detail with reference to the drawings and specific embodiments.

[0040] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 A preferred embodiment of the invention is shown. Its composition consists of lifting shaft 1, frame 2, drill rod control assembly 3, drill rod assembly 4, support connecting rod 5, drill rod guide plate assembly 6, combined cylinder fixing belt 7, load plate connecting rod 8, load bearing Plate 9, pulley 10, belt 11, control box 12, transmission shaft 13, drive gear 14, reducer 15, shaped brazing plate 16, shaped plate 17, combined cylinder 18, mud filling mold 19, propellant filling mold 20 , Effect body installation mold 21, paper bar combination plate 22, paper bar 23, drill rod length control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com