Assembling type movable cable holder for laying medium/high-voltage cable line in long-distance channel

A high-voltage cable, long-distance technology, used in pipeline supports, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of poor corrosion resistance, poor flexibility, complicated installation, etc., and achieve convenient processing and transportation, convenient installation, and reduced The effect of complicated welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

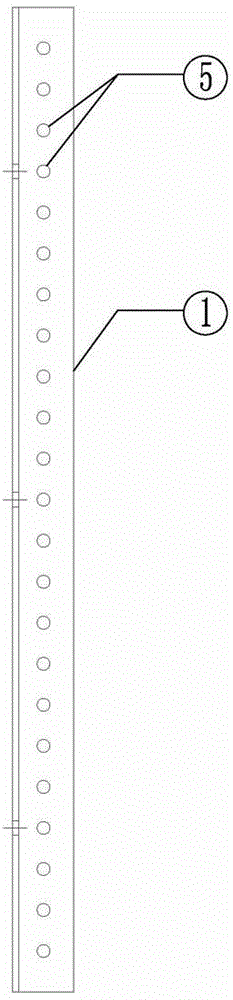

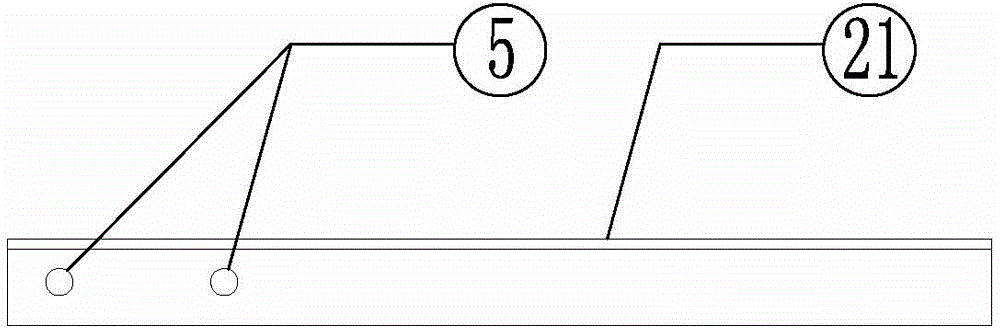

[0029] Embodiment 1: This embodiment is for the installation and use of cable brackets under the conditions of comprehensive pipe trenches, cable tunnels, and cable trenches. The column 1 and the cross arm 2 adopt angle steel, the back wall of the column 1 is 400mm apart and the waist-shaped connection hole 4 is punched, and the side wall is 50mm apart and the bolt connection hole 5 is drilled; the connection ends of the cross arm 2 are two 100mm apart. Bolt connection holes 5, and make the angle α between the connection line of the two bolt connection holes 5 and the horizontal line be 2 degrees; the reinforcement plate 3 is a steel plate, and three bolt connection holes are drilled on the reinforcement plate 3 5. Make the positions of the three bolt connection holes correspond to the bolt connection holes of the column and the cross arm, that is, the first bolt connection holes 351 and the second bolt connection holes 352 are arranged vertically and vertically at an interval ...

Embodiment 2

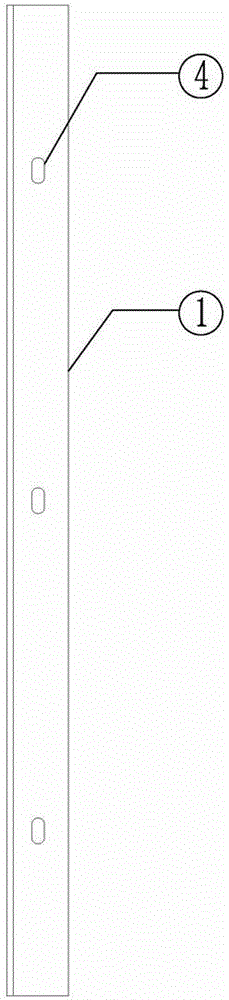

[0030] Embodiment 2: The column 1 described in this embodiment adopts channel steel, and the cross arm 2 adopts angle steel. The back wall of the column 1 is 400mm away from the waist type connection hole 4, and the side wall is 50mm apart and the bolt connection hole 5 is punched; Two bolt connection holes 5 with a distance of 100 mm are drilled at the connection end of the load 2. The reinforcing plate 3 is made of a steel plate. The first bolt connection holes 351 and the second bolt connection holes 352 are vertically arranged at an interval of 50 mm. The distance from the third bolt connection hole 353 is 100mm, and the column 1 is connected and fixed with the wall through the waist-shaped connection hole 4 with the expansion bolt 7; On the outer side of the steel column 1, the reinforcing plate 3 is placed between the column and the cross arm, and is closely attached to the back of the angle steel cross arm 2. There is no gap between the cross arm 2 and the reinforcing pl...

Embodiment 3

[0031] Embodiment 3: This embodiment is for the installation and use of the cable gantry in the case of the cable pipe well and the cable shaft. The gantry columns of the plumbing well and the vertical shaft are respectively fixed to the side and bottom of the wall to support the cables and adjust the layer spacing of the cable support, and adjust the height difference between the two ends of the plumbing well and the vertical shaft. Since the cables are often arranged in a square or horizontal manner, the cables 10 need to be fixed with hoops at a certain distance. The column 1 in this embodiment is the same as that in the second embodiment. and the hoop cross-arm 23, the two ends of the gantry cross-arm 22 and the hoop cross-arm 23 are punched with two bolt connection holes 5 at a distance of 100 mm, and the gantry cross-arm 22 and the hoop cross-arm 23 are connected in an external manner. Connect and fix with the column 1 respectively, install and connect the hoop 9 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com