Lubricant additive

A lubricating oil additive and adhesive technology, which is applied in the field of lubricating oil, can solve problems such as severe operating conditions, large equipment, and high energy consumption, and achieve the effects of protecting the environment, reducing exhaust emissions, and strong compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

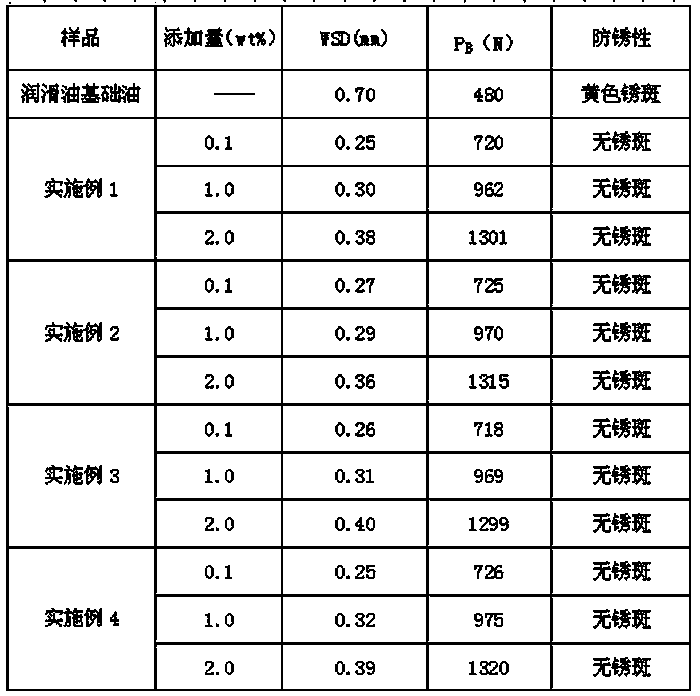

Examples

Embodiment 1

[0013] This lubricating oil additive is made by mixing the following raw materials: 3kg of N,N'-di-sec-butyl-p-phenylenediamine, 6kg of di-tert-butyl-p-cresol, 2kg of polyvinyl alcohol, 1kg of polybutene, dodecylbenzene 3kg of sodium sulfonate, 2kg of magnesium silicate, 3kg of fluorosurfactant, 4kg of dibenzyl disulfide, 3kg of dibutyl phosphite and 1kg of barium phosphide polyisobutylene.

Embodiment 2

[0015] This lubricating oil additive is made by mixing the following raw materials: 4kg of N,N'-di-sec-butyl-p-phenylenediamine, 5kg of di-tert-butyl-p-cresol, 3kg of polyvinyl alcohol, 1.5kg of polybutylene, dodecylbenzene 4kg of sodium sulfonate, 1.5kg of magnesium silicate, 4kg of fluorosurfactant, 5kg of dibenzyl disulfide, 2kg of dibutyl phosphite and 2kg of barium phosphide polyisobutylene.

Embodiment 3

[0017] This lubricating oil additive is made by mixing the following raw materials: N,N'-di-sec-butyl-p-phenylenediamine 5kg, di-tert-butyl-p-cresol 4kg, polyvinyl alcohol 4kg, polyisobutylene 2kg, dodecylbenzenesulfon 5kg of sodium phosphate, 2kg of magnesium silicate, 5kg of fluorosurfactant, 6kg of dibenzyl disulfide, 3kg of dibutyl phosphite, and 3kg of sulfur-phosphorylated polyisobutylene barium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com