Paint for pattern-printed tableware and implementation method thereof

A technology for tableware and coatings, applied in the field of tableware coatings, can solve the problems of poor scratch resistance of silicone coatings, poor functionality of hard oxide layers, insufficient protection of substrates, etc. colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

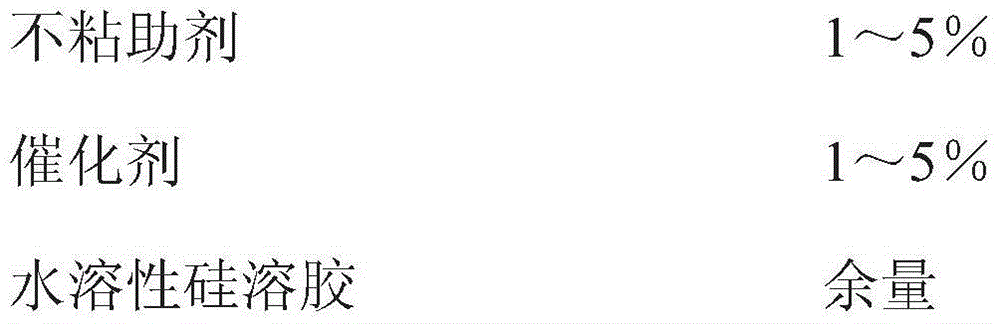

[0035] A kind of coating that is used for the tableware that is printed with pattern, the mass percent of its coating is:

[0036]

[0037] The filler is one or more of silicon dioxide whiskers, aluminum oxide whiskers, nanoscale precipitated barium sulfate, and kaolin.

[0038] The pigment is one or more of titanium dioxide, iron chrome brown, cobalt blue, titanium nickel yellow and titanium green.

[0039] The particle size of the water-soluble silica sol is 30-100 nanometers.

[0040] The catalyst is one or more of zinc naphthenate, zirconium naphthenate and potassium acetate.

[0041] Described non-stick auxiliary agent is commercially available product;

[0042] The siloxane is a mixture of basic components and functional components, the basic component is a mixture of methyltrimethoxysilane, methyltriethoxysilane and tetraethyl orthosilicate, the three The molar ratio is 1:1:2.5.

[0043] The functional component is a mixture of β-heptamethyltrisiloxane-ethyltrime...

Embodiment 2

[0052] A kind of coating that is used for the tableware that is printed with pattern, the mass percent of its coating is:

[0053]

[0054] A kind of implementation method of the coating that is used for printing the tableware of pattern, is the same as embodiment 1.

Embodiment 3

[0056] A kind of coating that is used for the tableware that is printed with pattern, the mass percent of its coating is:

[0057]

[0058] A kind of implementation method of the coating that is used for printing the tableware of pattern, is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com