Method for improving properties of starch-base edible packaging film by adding hydrophilic colloid

A hydrophilic colloid and starch-based technology, which is applied in the field of starch application and food packaging materials, can solve the problems of ordinary starch-based coating development limitations, high humidity sensitivity, poor mechanical properties, etc., to improve mechanical properties and softness Sexuality, rich sources, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

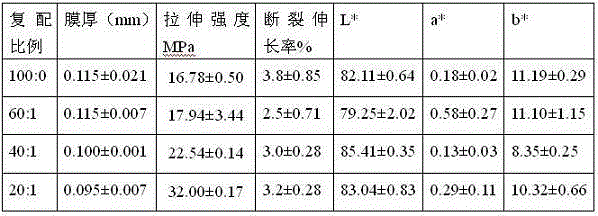

[0023] 25g of water, waxy sweet potato starch with an amylose content of 1% and guar gum were mixed in proportions of 100:0, 60:1, 40:1, 20:1 (mass ratio, g / g) Make a suspension with a mass fraction of 6% (on a dry basis), and then gelatinize in a boiling water bath for 30 minutes. The gelatinized sample is degassed and poured into a 10×10cm flat plate. The sample is spread evenly, and then placed in 4h in an oven at 50°C.

[0024] The prepared starch film was placed in a constant temperature and humidity chamber with a temperature of 23 °C and a relative humidity of 50% for 1 day, and then used for the determination of mechanical properties and color difference. As shown in Table 1, the thickness of all starch films is about 0.1mm, and after adding guar gum, the tensile strength of the starch film increases, the elongation at break decreases, and the color of the composite film is dark yellow. However, the elongation at break and the color difference parameter values did n...

Embodiment 2

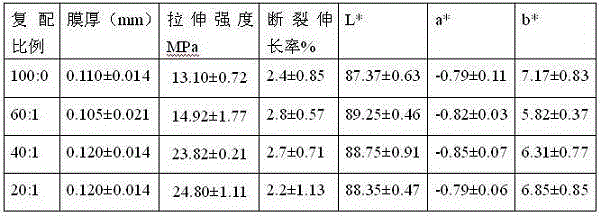

[0029] Mix 25g of water with 18% amylose content of ordinary cornstarch and xanthan gum at a compounding ratio of 100:0, 60:1, 40:1, 20:1 (mass ratio, g / g) and the compounding mass The suspension with a fraction of 4% (calculated on a dry basis) is then gelatinized in a boiling water bath for 30 minutes. The gelatinized sample is degassed and poured into a 10×10cm flat plate. The sample is spread evenly and placed at 50°C 4h in the oven.

[0030] The prepared starch film was placed in a constant temperature and humidity chamber with a temperature of 23 °C and a relative humidity of 50% for 1 day, and then used for the determination of mechanical properties and color difference. As shown in Table 2, the thickness of all starch films is about 0.1mm, and after adding xanthan gum, the tensile strength of the starch film increases, the brightness value of the composite film increases, and the color becomes brighter. However, the elongation at break and the color difference paramet...

Embodiment 3

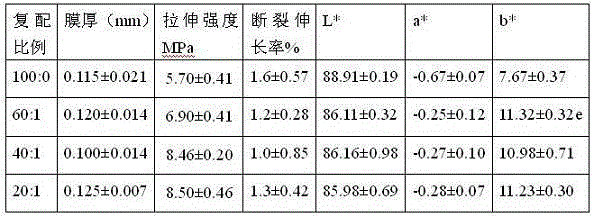

[0034] Mix 25g of water, amylose content of 45% high amylose sweet potato starch and guar gum in a compounding ratio of 100:0, 60:1, 40:1, 20:1 (mass ratio, g / g) and the compounding mass The fraction is 5% (on a dry basis), the suspension is placed in a pressure bottle and swells in a boiling water bath for 15 minutes, and then placed in an oven at 130°C for 30 minutes. The gelatinized sample was degassed and poured into a flat plate of 10×10 cm. The sample was evenly spread, and then placed in an oven at 50°C for 4 hours.

[0035] The prepared starch film was placed in a constant temperature and humidity chamber with a temperature of 23 °C and a relative humidity of 50% for 1 day, and then used for the determination of mechanical properties and color difference. As shown in Table 3, the thickness of all starch films was around 0.1 mm, and after adding guar gum, the tensile strength of starch films increased and the elongation at break decreased. However, the elongation at br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com