Preparation method of methyl stearate

A technology of methyl stearate and stearic acid, applied in the field of preparation of methyl stearate, can solve the problems of long reaction time, high reaction temperature, large energy consumption, etc., achieves simple preparation method and improves reaction conversion rate , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention discloses a method for preparing methyl stearate, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

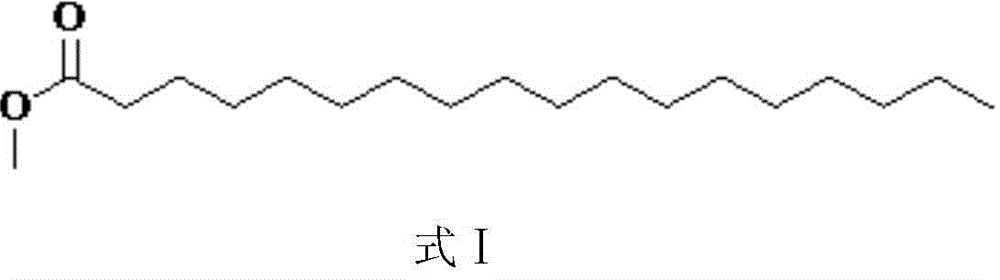

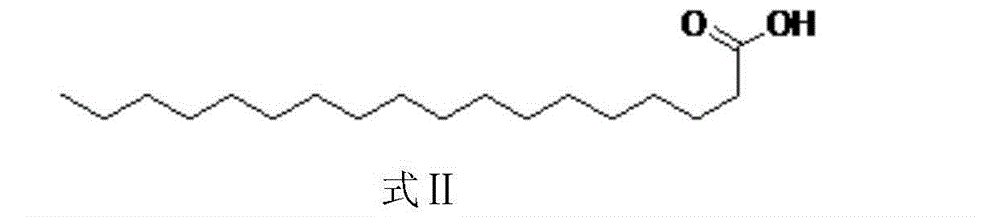

[0014] The invention provides a method for preparing methyl stearate, a compound whose structure is shown in formula I. Concentrated sulfuric acid is used as a catalyst, carbon black is used as a wav...

Embodiment 1

[0022] The addition of embodiment 1 carbon black is to the influence of synthetic reaction

[0023] Concentrated sulfuric acid is used as a catalyst, carbon black is used as a wave absorbing agent, stearic acid and anhydrous methanol are used as raw materials, and conventional water bath heating and microwave heating as a wave absorbing agent are respectively used as reaction conditions to carry out esterification reaction. Time and conversion rate were analyzed, and the results are shown in Table 1:

[0024] Table 1 The influence of microwave heating and the addition of carbon black on the reaction

[0025]

[0026] Among them, the conversion rate calculation formula is as follows:

[0027]

[0028] Table 1 data shows: take carbon black as the synthetic reaction of wave absorbing agent under microwave condition, the productive rate of methyl stearate can be brought up to 98.5% by 83.5%, shortened the time of synthetic reaction simultaneously, and the reaction time is s...

Embodiment 2

[0029] The preparation of embodiment 2 methyl stearate

[0030] In a 125mL microwave reactor with stirrer, condenser and oil-water separator, add stearic acid 0.05mol (14.3g), methanol 0.70mol (22.4g), concentrated sulfuric acid 0.22g (0.002mol), carbon black 0.18g (0.015mol), reacted under microwave power 130w for 3min, after the reaction, washed the product with hot water in a separatory funnel until pH = 7, separated, distilled under reduced pressure, and collected fractions at 195-199°C to obtain Ethyl stearate was 14.68g, and the conversion rate was 98.52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com