Sewage treatment method and sewage treatment system

A sewage treatment method and sewage treatment system technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as long construction period, waste of resources, and difficult management , to achieve the effect of short construction period, good control and management, and simple civil construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

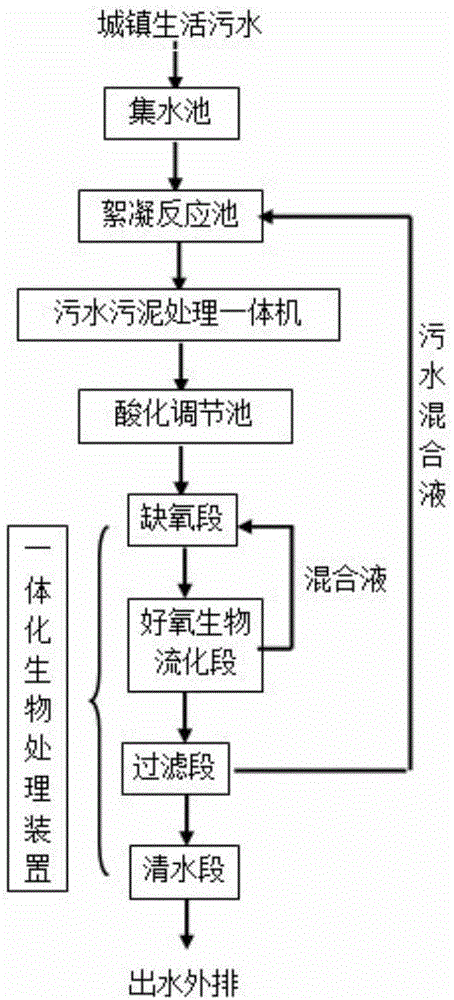

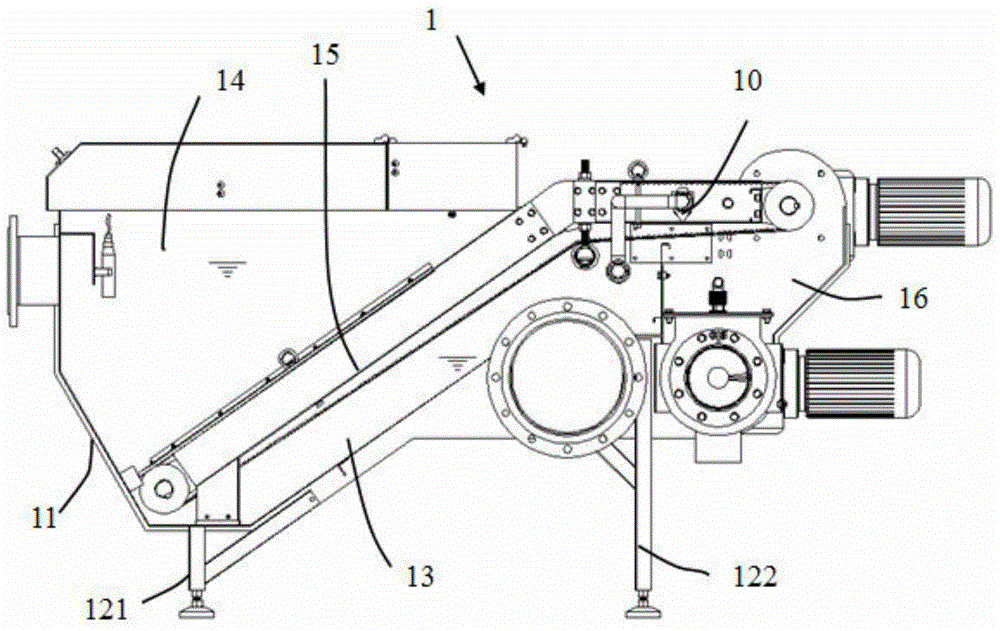

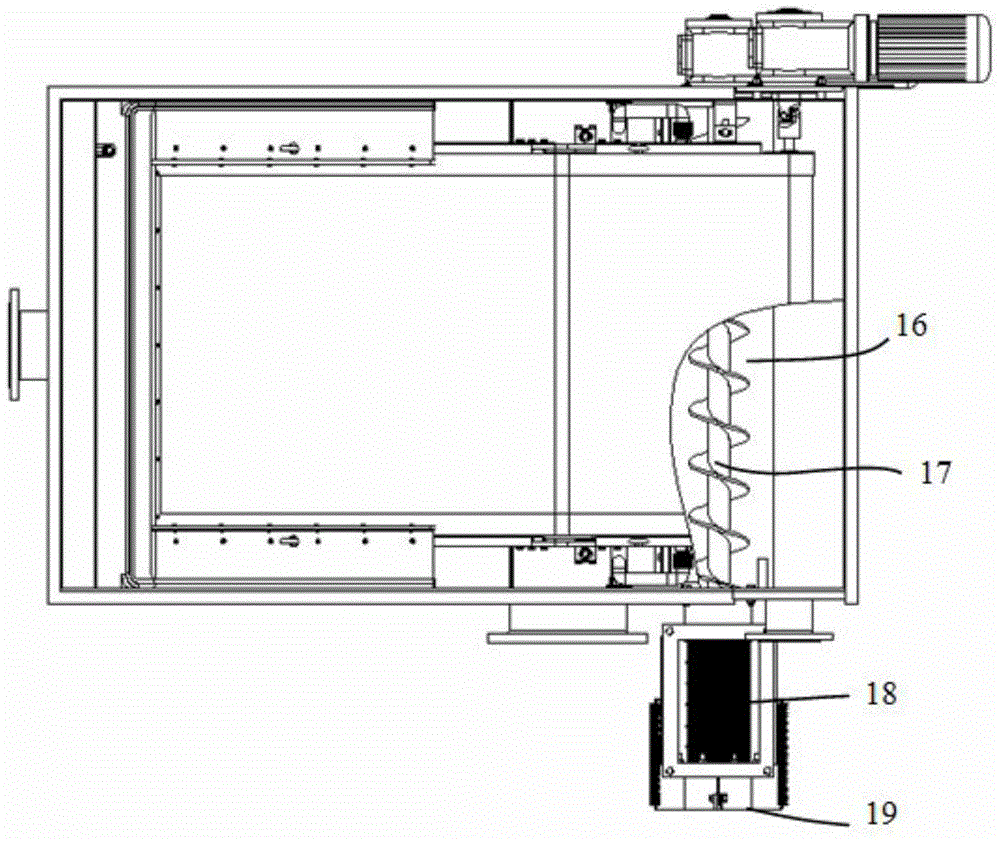

[0027] Participate in combination Figure 2 to Figure 4 , The sewage treatment system in a preferred embodiment of the present invention includes a coarse grid, a water collection tank, a flocculation reaction tank, an integrated sewage sludge treatment machine 1, an acidification adjustment tank and an integrated biological treatment device 2 in sequence. The coarse grid is used to intercept and remove large suspended particles with a diameter larger than 10 mm.

[0028] The integrated sewage sludge treatment machine 1 includes a housing 11 and a front leg 121 and a rear leg 122 for supporting the housing 11 . The casing 11, the front leg 121 and the rear leg 122 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com