Hospital sewage fully enclosed treatment technology and integrated equipment

A treatment process, fully enclosed technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Disinfectant waste and other problems, to achieve the effect of simple civil construction and installation and debugging, saving implementation time, and lasting sterilization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

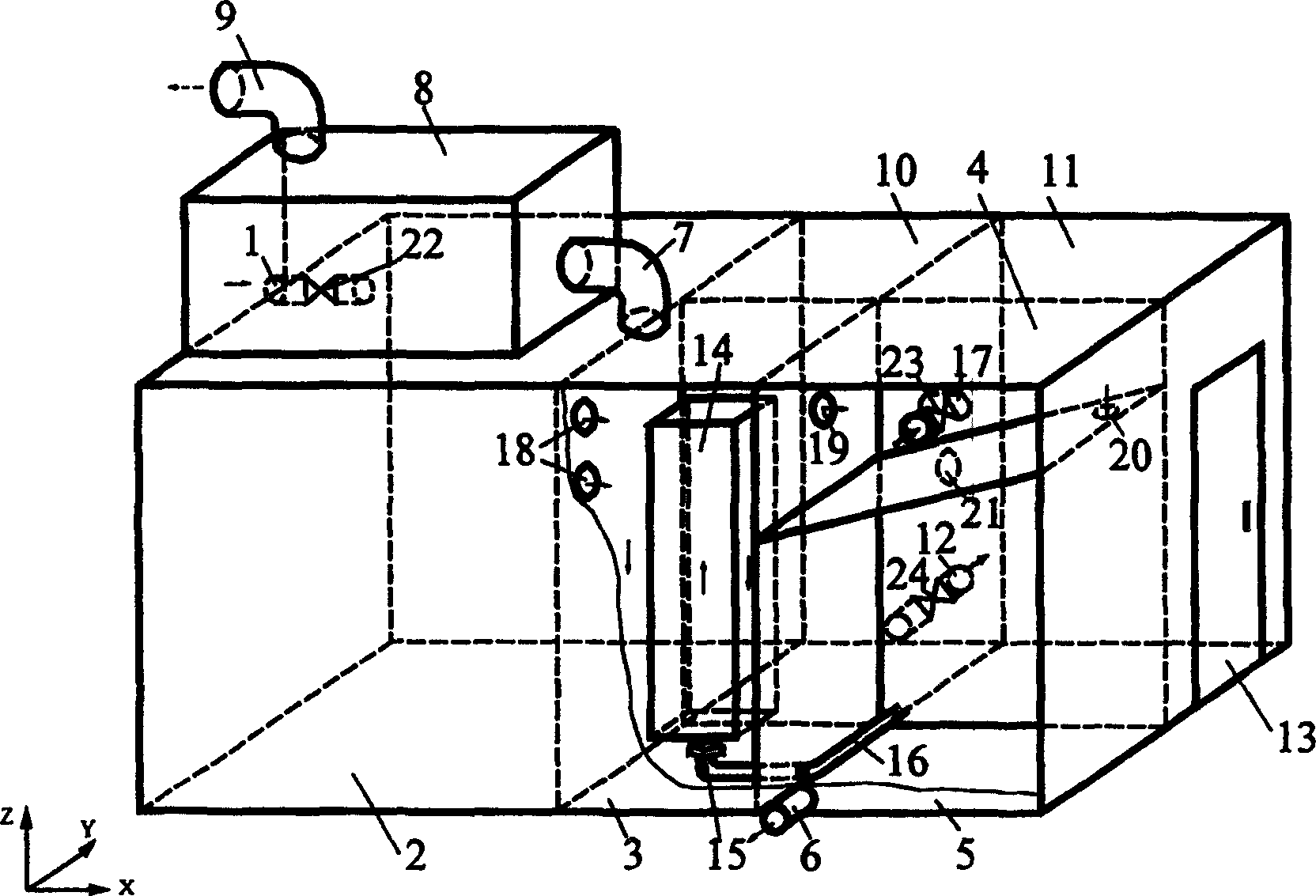

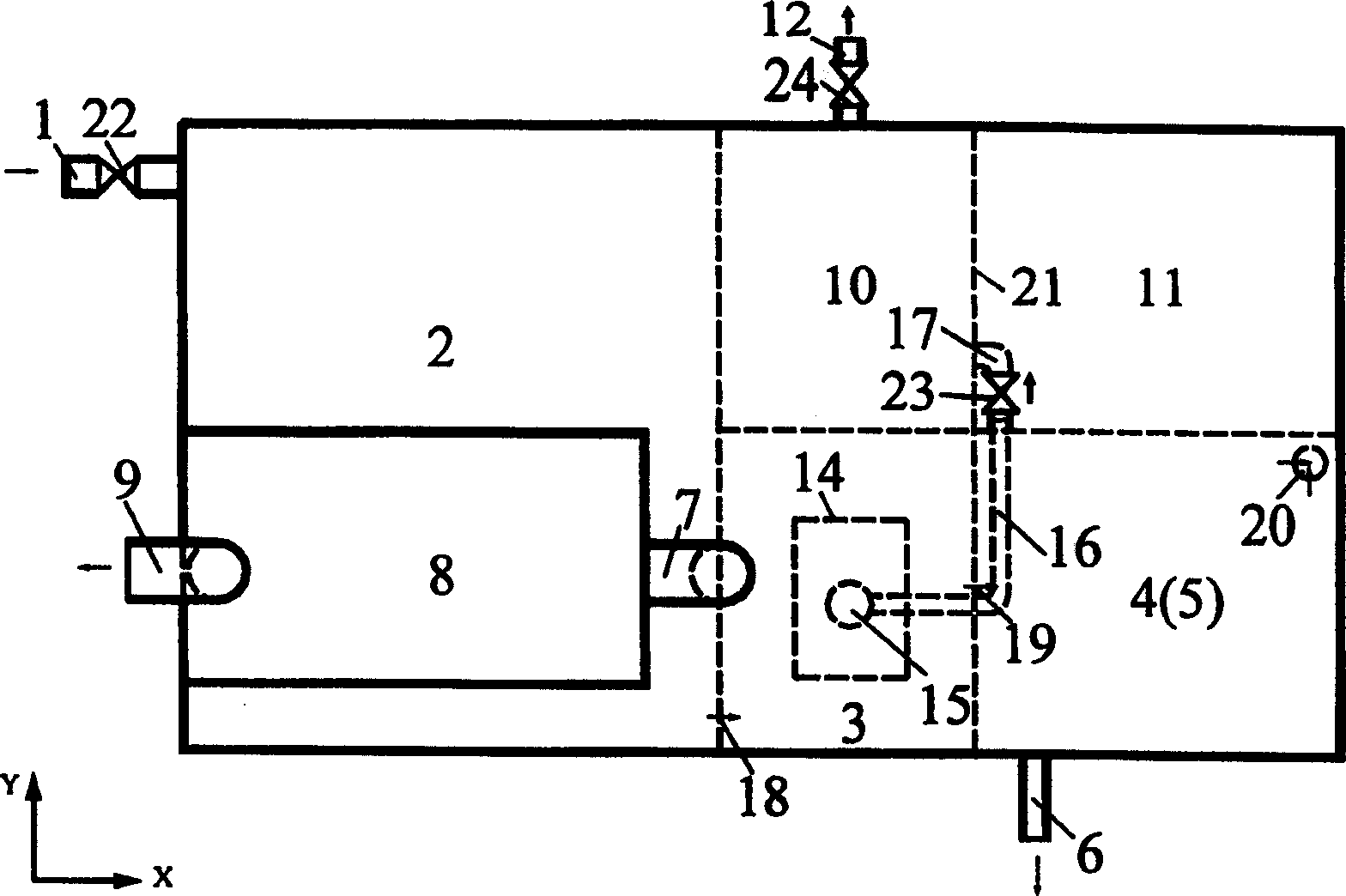

[0024] The specific structure, working process and best embodiments of the present invention will be further described below in conjunction with the drawings.

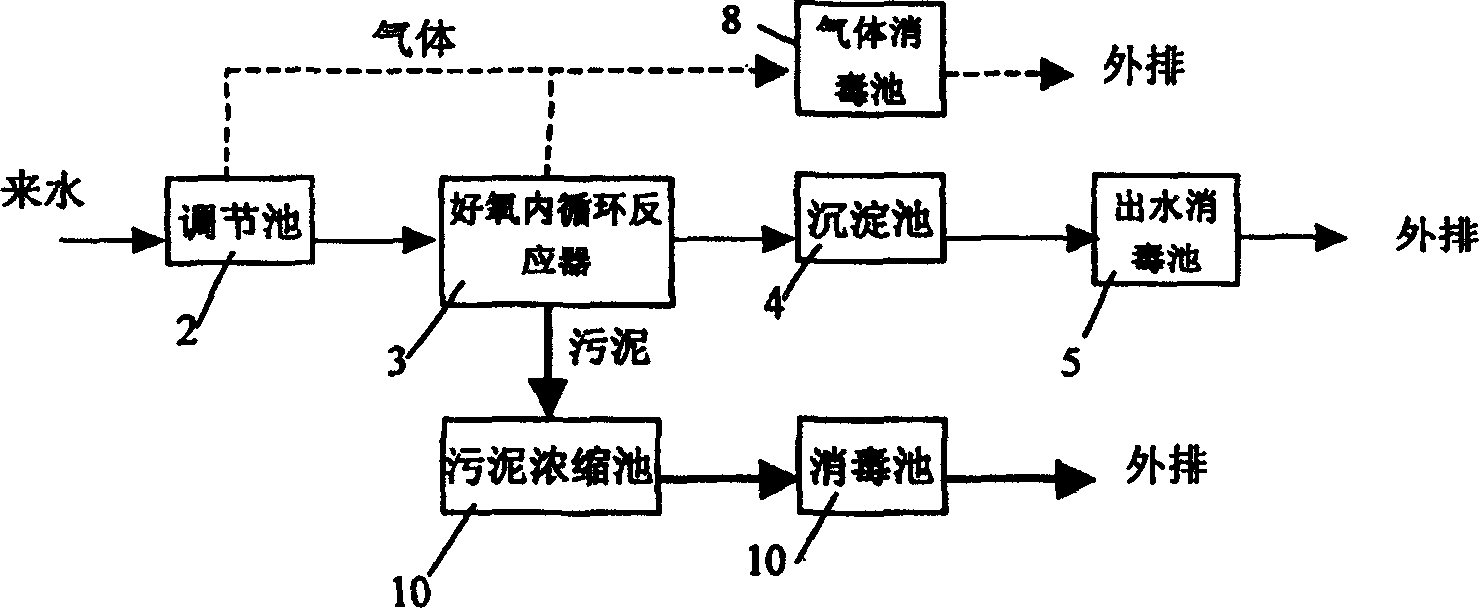

[0025] figure 1 It is a process flow chart of hospital sewage treatment provided by the present invention. The hospital sewage enters the regulating tank 2 set in the fully enclosed box through the water inlet pipe 1. Its water level is controlled by the liquid level gauge, and enters the aerobic internal circulation reaction tank 3 adjacent to the regulating tank through the water hole 18 for treatment. Most of the organic matter is After degradation, the sewage passes through the water hole 19 and enters the sedimentation tank 4 beside the reaction tank for solid-liquid separation. The clean water flows through the water hole 20 into the effluent disinfection tank 5 arranged at the lower part of the sedimentation tank for chlorine dioxide disinfection and discharge; The sludge produced by the oxygen reaction enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com