Straddle type monorail vehicle body supporting structure and vehicle lifting method thereof

A straddle-type monorail and support structure technology, applied in the field of rail transit, can solve the problems of increasing construction difficulty and construction cost, and achieve the effect of improving the space utilization rate in the warehouse, high work efficiency, and reducing the risk of casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

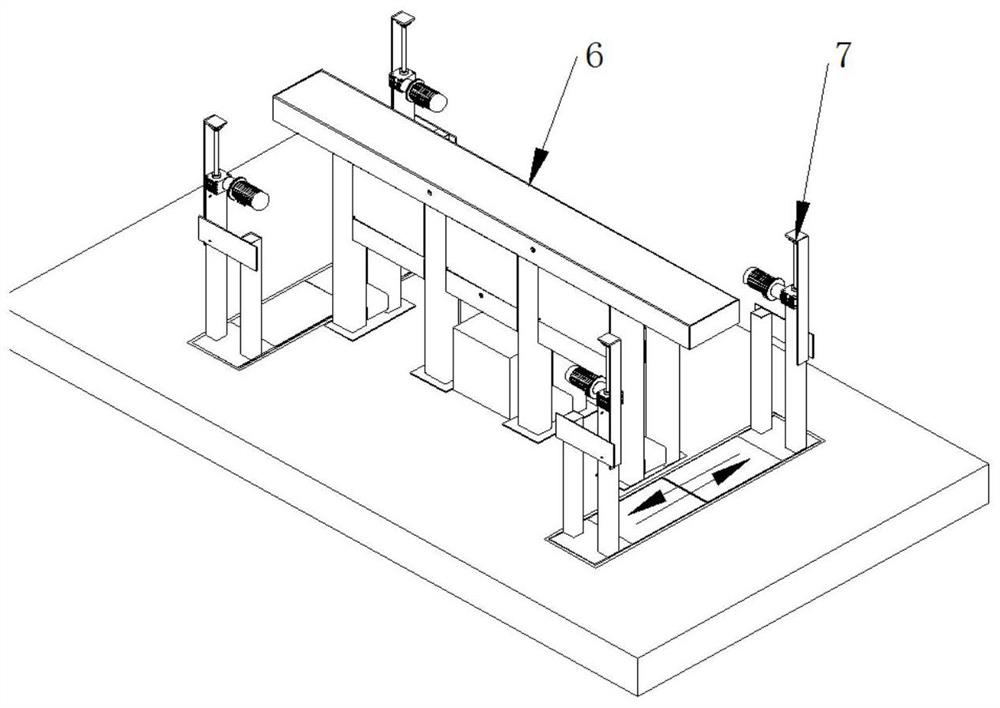

[0038] like Figure 1-4 As shown, the present embodiment provides a straddle type monorail vehicle body support structure, including: a rail beam 6, at least one upright column is arranged below the rail beam 6, and the upright column is arranged on the operating table;

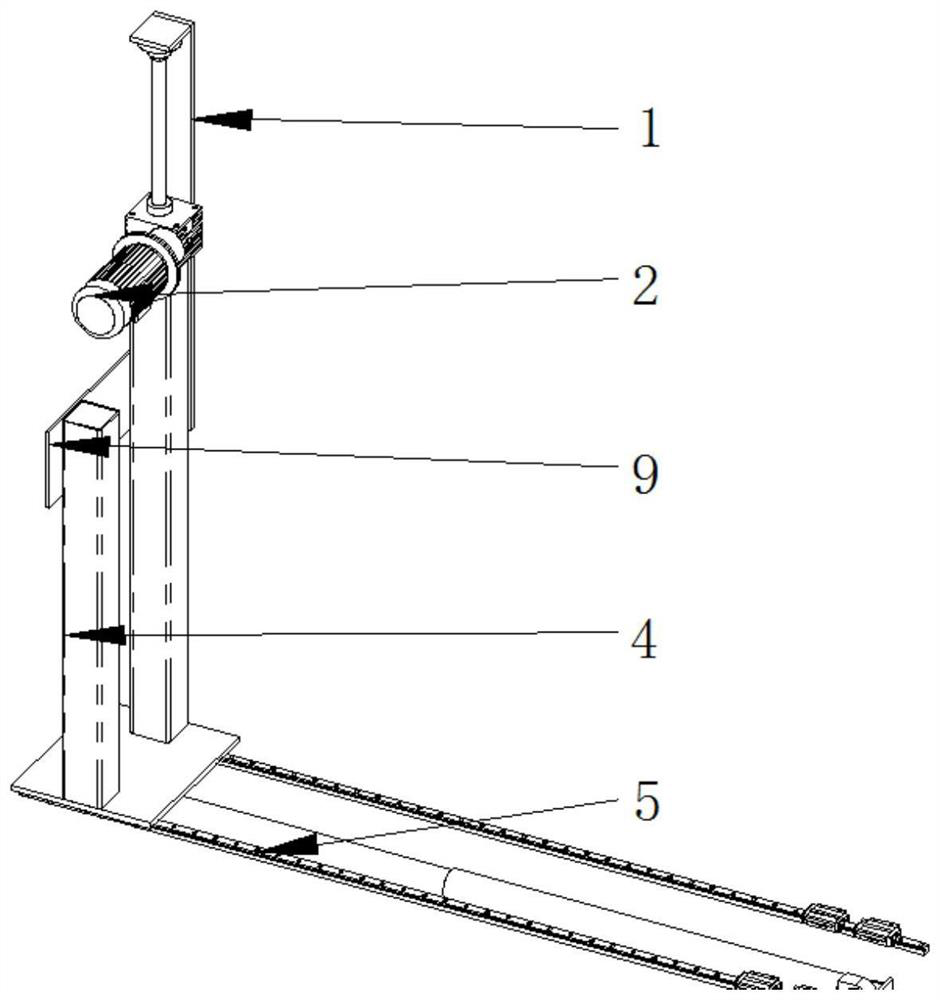

[0039] Vehicle body support structure, the vehicle body support structure is divided into two groups, the two groups of vehicle body support structures are respectively arranged on both sides of the track beam 6, and each group of vehicle body support structures has two cranes 7, and the crane 7 includes a frame 4. Lifting mechanism 2 and translation mechanism 5, the lifting mechanism 2 is connected above the frame 4, the translation mechanism 5 is connected under the frame 4, and the translation mechanism 5 is set on the operating table; The carriage 7 is located below the rail beam 6; when the carriage 7 is in the working state, the carriage 7 is located below the stand-by point.

[0040] In some alternati...

Embodiment 2

[0051] like Figure 5 and Image 6 As shown, the present embodiment provides a method for mounting a straddle-type monorail vehicle, comprising the following steps:

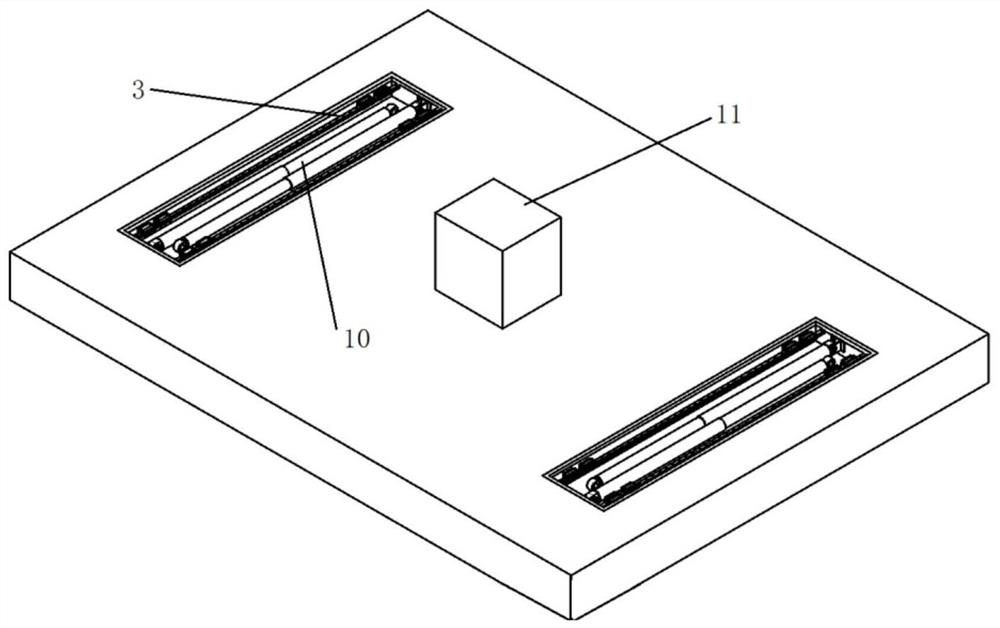

[0052] S1: The hydraulic cylinder 10 is raised, and under the guidance of the linear slide rail 3, the crane 7 is translated to the bottom of the crane point;

[0053] S2: Raise the screw jack, fix the car body, and manually remove the bogie for maintenance;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com