Rotating machine, continuous winding coil, distributed winding stator and method for forming same

A technology of rotating electric machines and winding coils, applied in the shape/style/structure of winding conductors, electric components, manufacturing motor generators, etc., which can solve problems such as current density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

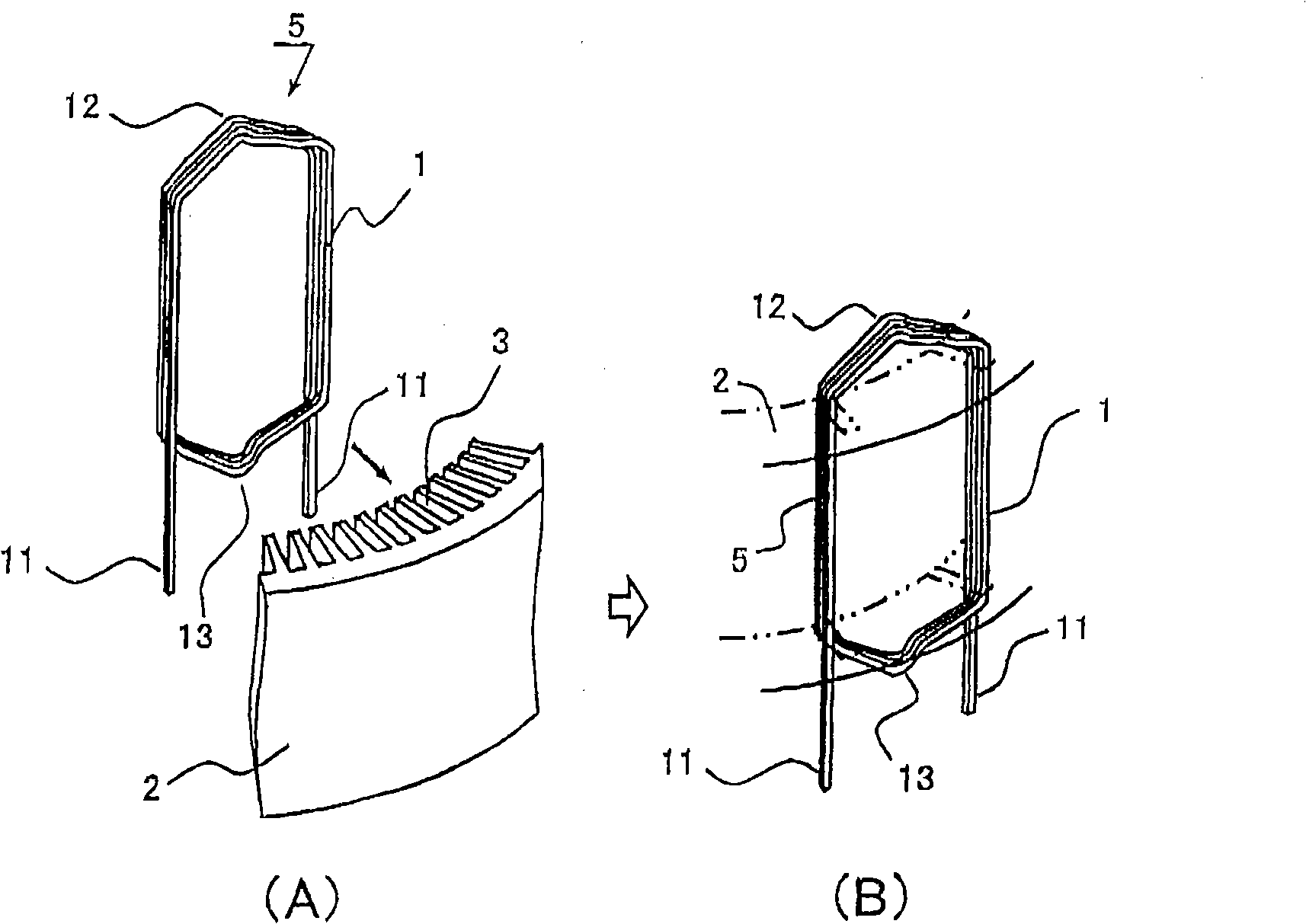

[0032] figure 1 The form-wound coil type structure of Example 1 of the present invention is shown. figure 1 (A) is a perspective view before the form-wound coil 5 is incorporated into the stator core 2, and the stator core 2 is cut and shown. figure 1 (B) is a perspective view showing a state where the form-wound coil 5 is incorporated into the stator core 2, and the outline of the stator core 2 is shown by a solid line and a two-dot chain line. The coil wire 1 is a copper corner wire covered with an enamel resin film. The stator core 2 is formed by press-cutting rolled steel plates with a thickness of about 1 mm and laminating them. Continuously wind the coil wire material 1 (three turns in the figure) of the corner wire with the same length or similar size on both sides, and place the top 12 and the coil end side of the coil wire material 1 that is overlapped and wound along the layer direction. The top portion 13 is bent into a crank shape to form a die-wound coil. The ...

Embodiment 2

[0052] Figure 12 A partial cross-sectional view showing a stator slot 3 in a state where form-wound coils are formed from corner wires 1 coated with thermal adhesive 14 and incorporated into stator core 2 according to Embodiment 2 of the present invention. Two corner wires 1 are bonded together to form roughly one corner wire, and form-wound coils are formed. The thermal adhesive 14 is melted by heating at a predetermined temperature. Two angled wires 1 are superimposed, and bonding can be performed by applying heating and cooling. This results in a structure in which twelve corner wires 1 are arranged in one groove. Therefore, the magnetic flux density is further increased, the current density is reduced, and the efficiency as a rotating electrical machine can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com