Method and device for generating microbubble water

A production device and production method technology, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve problems such as waste of water resources, small number of micro-bubbles, and failure of micro-bubble water dispensers to avoid clogging, The effect of long-term reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

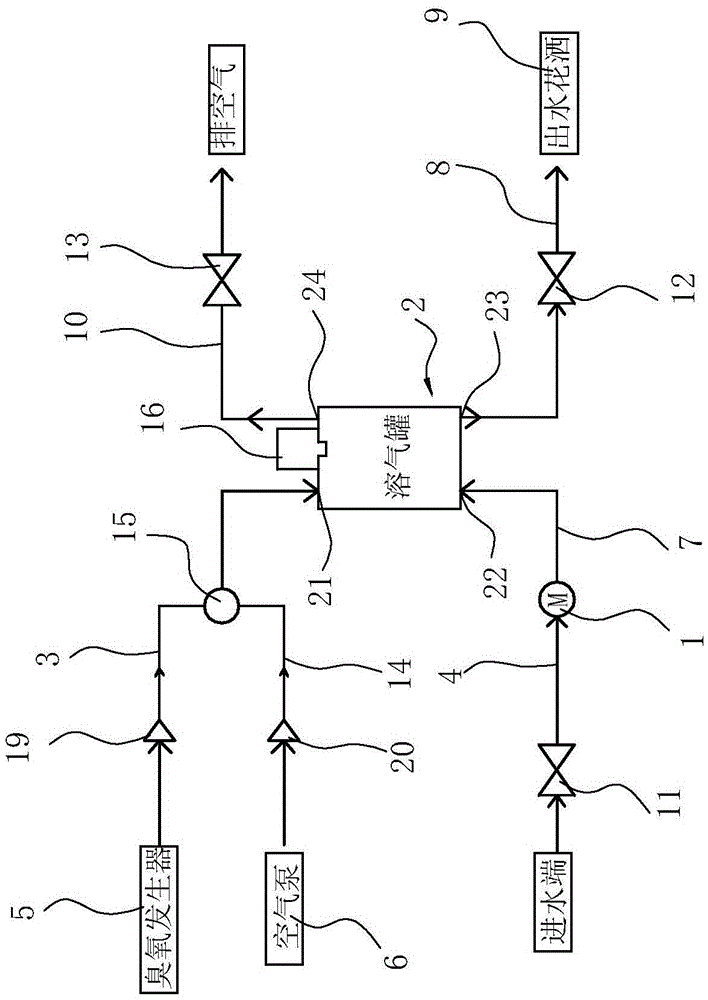

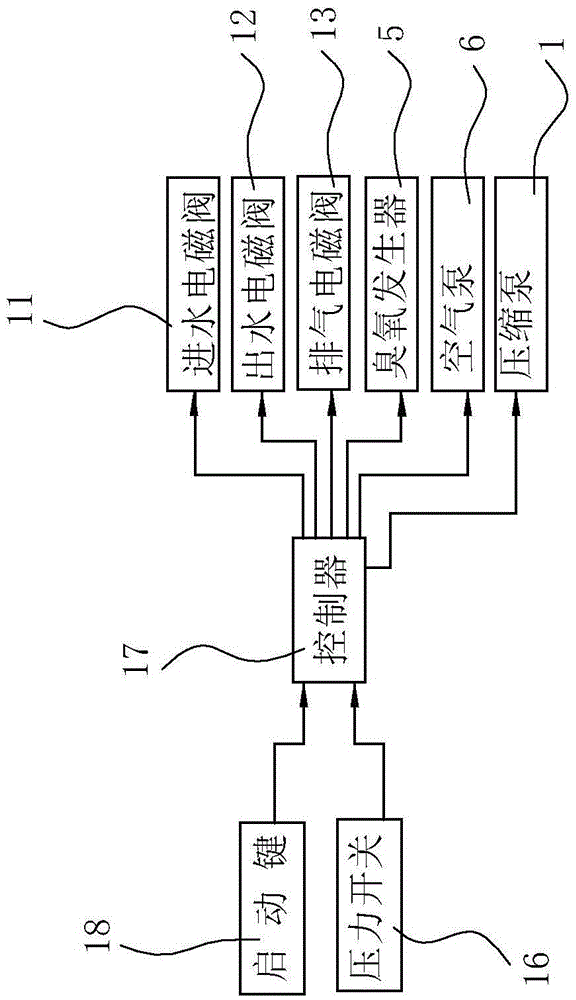

[0043] Such as figure 1 with figure 2 As shown, the microbubble water generating device is to pass a certain amount of ozone in the water, therefore, the delivery source of the gas to be inflated mentioned in the above method is an ozone generator, in order to make purer ozone microbubble water, in the above An "exhaust" step is also added between the ② step and the ③ step of the method. Specifically, the microbubble water generating device includes a compression pump 1, a dissolved air tank 2, an air inlet pipe 3, a water inlet pipe 4, an ozone generator 5 and an air pump 6, wherein the compression pump 1, the dissolved air tank 2, the air pump 6. Installed on the shell of the microbubble water generating device, the dissolved air tank 2 is provided with an air inlet 21, a water inlet 22, a water outlet 23 and an exhaust port 24 for outputting microbubble water, and the air inlet 21 passes through The inlet pipe 3 is connected to the outlet of the ozone generator 5, the wa...

no. 2 example

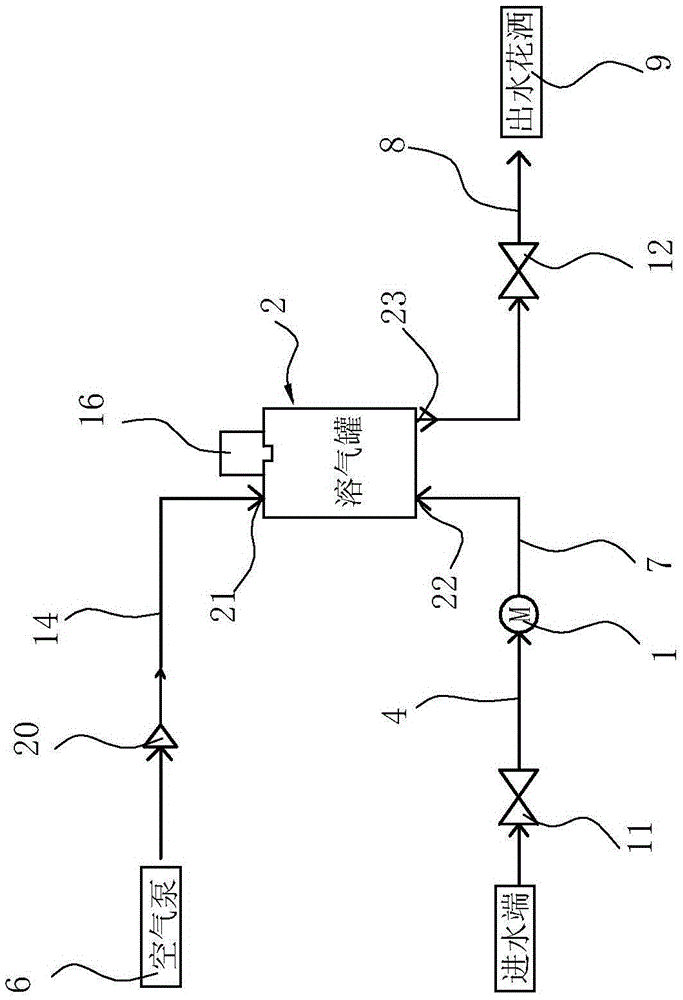

[0055] Such as image 3 with Figure 4 The difference between this microbubble water generating device and the above-mentioned first embodiment is that the air dissolved in the water does not need to exhaust the air in the dissolved air tank before the air intake, that is, there is no need to set up another air tank in the dissolved air tank 2. Exhaust port, exhaust pipe and exhaust solenoid valve, while removing the ozone generator and corresponding pipelines in Embodiment 1, the branch circuit is the intake pipe. The air pump is the delivery source of the gas to be inflated.

[0056] When in use, adopt the following specific methods to produce microbubble water:

[0057] ①. Turn on the power, and the microbubble water generating device is in standby state;

[0058] ②, press the start key 18, at this time the controller sends a signal to the air pump 6, the water inlet solenoid valve 11, and the water outlet solenoid valve 12, so that the water inlet solenoid valve 11, the...

Embodiment 3

[0065] Such as Figure 5 with Image 6 As shown, the difference between the microbubble water generating device and the above-mentioned first embodiment is: the difference of the drainage mechanism, that is, the air pump 6 and the branch circuit and the second one-way valve 20 in the first embodiment are canceled, and the An air delivery pipe 25 communicating with the water inlet pipe is provided, and an air delivery solenoid valve 26 connected with the input end of the controller is installed on the air delivery pipe 25 .

[0066] During use, the difference between the microbubble water generation method and the method of the above-mentioned first embodiment is: the 6th and 7th steps are different, that is, in the present embodiment:

[0067] ⑥. Compression pump 1 continues to work until the required ratio is reached between the input amount of water and the amount of ozone input into the dissolved air tank before. During specific control, the ratio can be controlled by micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com