Method for preparing large-size high-quality graphene with controllable number of layers

A high-quality, graphene technology, which is applied in the field of large-size, high-quality graphene preparation with a controllable number of layers, can solve the problems of reduced electrical conductivity and large graphene defects, and achieves controllable layers, simple processes, and high production efficiency. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

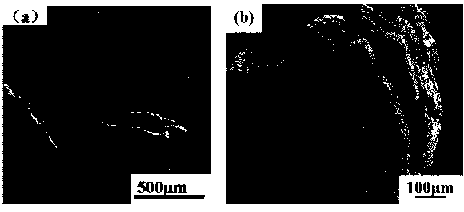

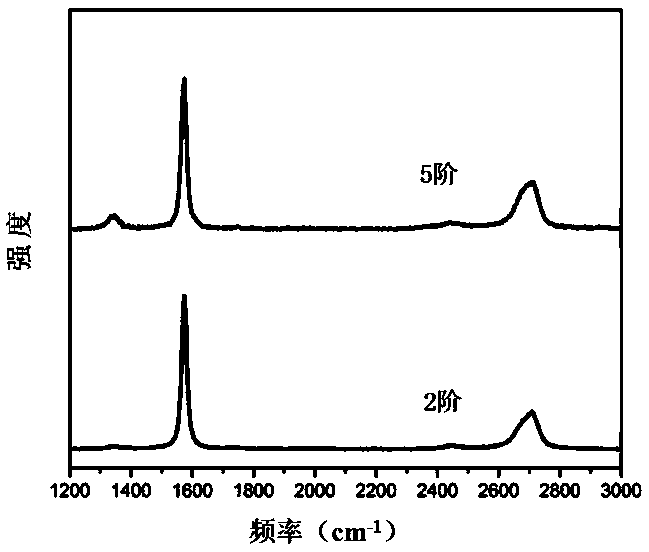

[0034] Put 1 g flake graphite (500 μm particle diameter, carbon content >95%), 5 g chromium trioxide and 0.6 g potassium permanganate into a 100 mL single-necked round bottom flask, then add 12 mL glacial acetic acid (99.5% ), stirred and reacted in a water bath at 45°C for 2 days, filtered, washed repeatedly with water and acetone to remove unreacted chromium trioxide, and dried in a vacuum oven at 65°C to obtain 5th order GICs, as figure 1 As shown in a, its Raman spectrum is shown as figure 2 shown. From figure 2 It can be seen that the I of GICs D / I G The value is very small, indicating that there are few defects in the sheet and the degree of oxidation is low.

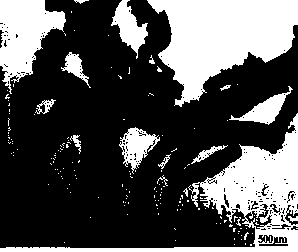

[0035] Then, 0.1 g of 5th-order GICs was put into 20 mL of hydrogen peroxide (30%), and after reacting at room temperature for 2 days, it was found that the graphite was continuously expanding, filtered, and washed with water to obtain worm-like graphene aggregates. The morphology of the swelling was observe...

Embodiment 2

[0038] Put 1 g flake graphite (500 μm particle diameter, carbon content >95%) and 17 g chromium trioxide into a 100 mL double-necked round bottom flask, set up an exhaust gas absorption device, and then add 14 mL concentrated hydrochloric acid (38% ), stirred the reaction in a water bath at 45 °C, and absorbed the tail gas with sodium hydroxide. After 2 days, it was filtered, washed repeatedly with water and acetone to remove unreacted chromium trioxide, and dried in a vacuum oven at 65 °C to obtain the second-order GICs.

[0039] Then, 0.1 g of the second-order GICs was put into 20 mL of hydrogen peroxide (30%), reacted at room temperature for 2 days, filtered and washed with water to obtain worm-like graphene aggregates.

[0040] Finally, the worm-like graphene aggregates were placed in 100 mL NMP for 30 min in a water bath to obtain a black suspension, which was centrifuged at 12000 rpm for 10 min, the upper layer was discarded, and NMP was added, centrifuged at 12000 rpm f...

Embodiment 3

[0042] Put 1 g flake graphite (particle diameter 500 μm, carbon content >95%) and 3 g chromium trioxide into a 100 mL single-necked round bottom flask, then add 10 mL glacial acetic acid (99.5%), and reflux at 122 °C After 2 h, filter, wash repeatedly with water and acetone to remove unreacted chromium trioxide, and dry in a vacuum oven at 65 °C to obtain third-order GICs.

[0043] Then, 0.1 g of third-order GICs was put into 20 mL of hydrogen peroxide (30%), reacted at room temperature for 2 days, filtered, and washed with water to obtain worm-like graphene aggregates.

[0044] Finally, the worm-like graphene aggregates were placed in 100 mL NMP for 30 min in a water bath to obtain a black suspension, which was centrifuged at 12000 rpm for 10 min, the upper layer was discarded, and NMP was added, centrifuged at 12000 rpm for 10 min, and repeated After centrifugation for 3 times, add NMP to the lower layer, centrifuge at 500 rpm for 30 min, repeat centrifugation and collect th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com