Machine specially used for punching water gap

A technology of water cutting and special plane, which is applied in the field of automotive equipment, can solve problems such as troublesome operation, time-consuming and labor-intensive work, and poor stability, and achieve the effects of saving manpower, reducing labor intensity, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

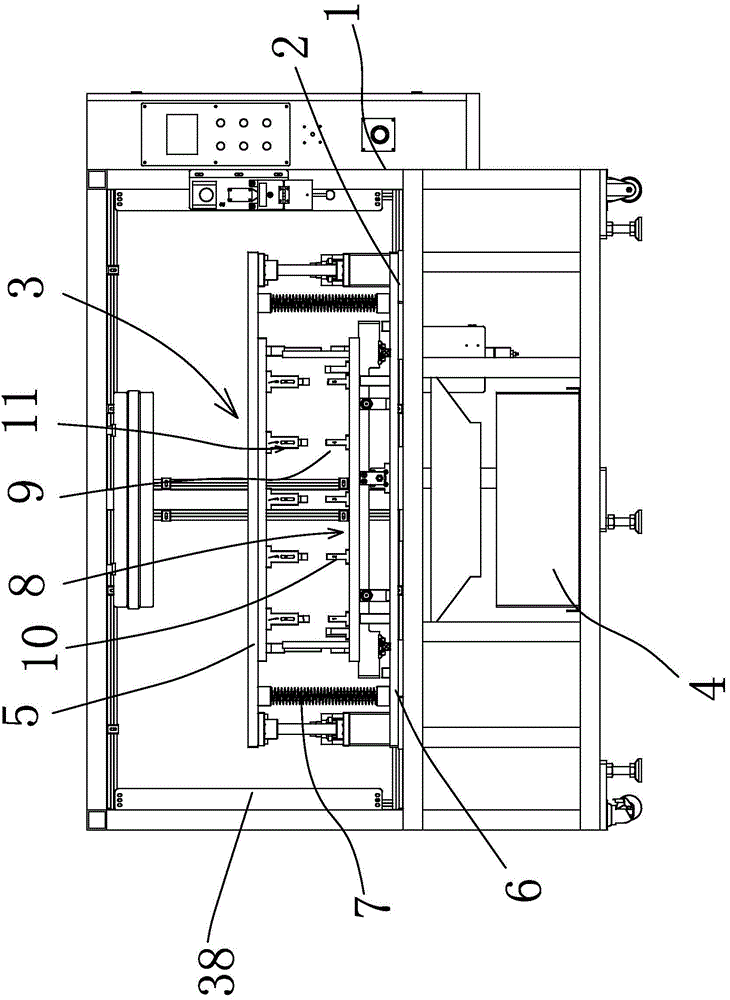

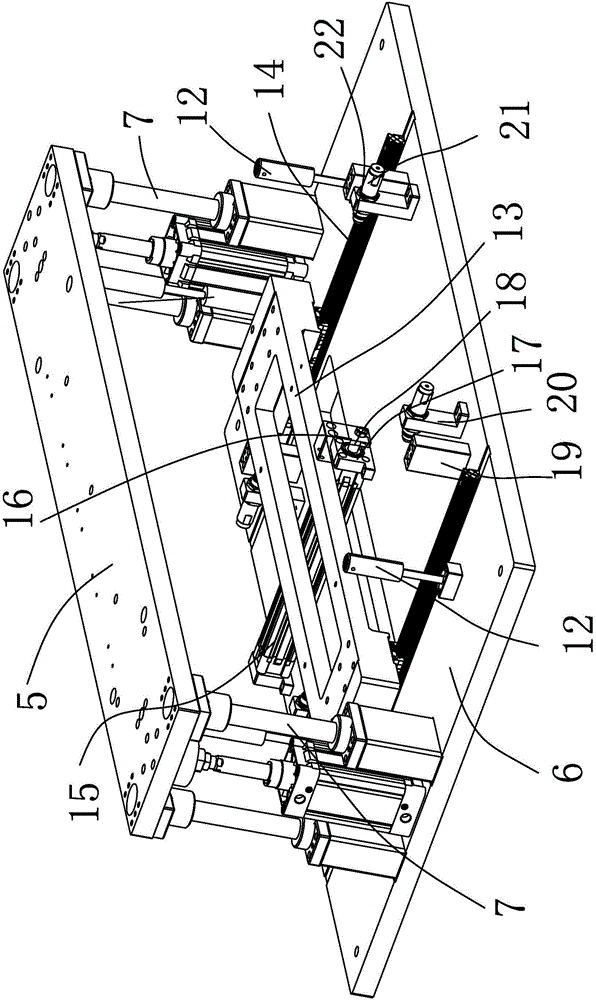

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

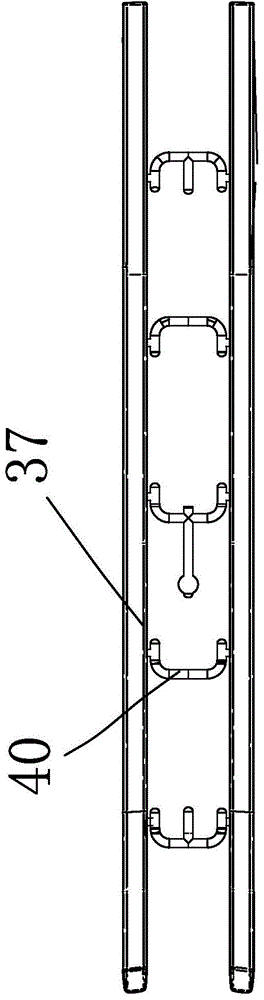

[0022] In the figure, frame 1; workbench 2; stamping nozzle mold 3; waste funnel 4; upper template 5; lower template 6; guide post 7; worktable mechanism 8; product positioning mechanism 9; Mechanism 11; mold change placement block 12; moving platen 13; guide rail 14; drive cylinder 15; fixed block 16; guide block 17; cylinder rod 18; end limit block 19; slow block 20; slow head 21; Relief spring 22; end support block 23; stop head 23a; middle support block 24; first knife-edge block 25; second knife-edge block 26; first knife-edge head 27; Part 29; the second lower tough knife-edge surface 30; avoidance groove 31; upper knife block 32; preloading device 33; preloading block 34; preloading spring 35; Knife head 39; excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com