Manufacturing method of spray-coated metallized steel pipe

A manufacturing method and technology for metal pipes, which are applied in the direction of metal material coating process, superimposed layer plating, coating, etc., can solve problems such as spalling of sprayed metal layers, corrosion resistance of steel pipes, cracks, etc., and achieve increased design. The effect of freedom, inexpensive equipment investment, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

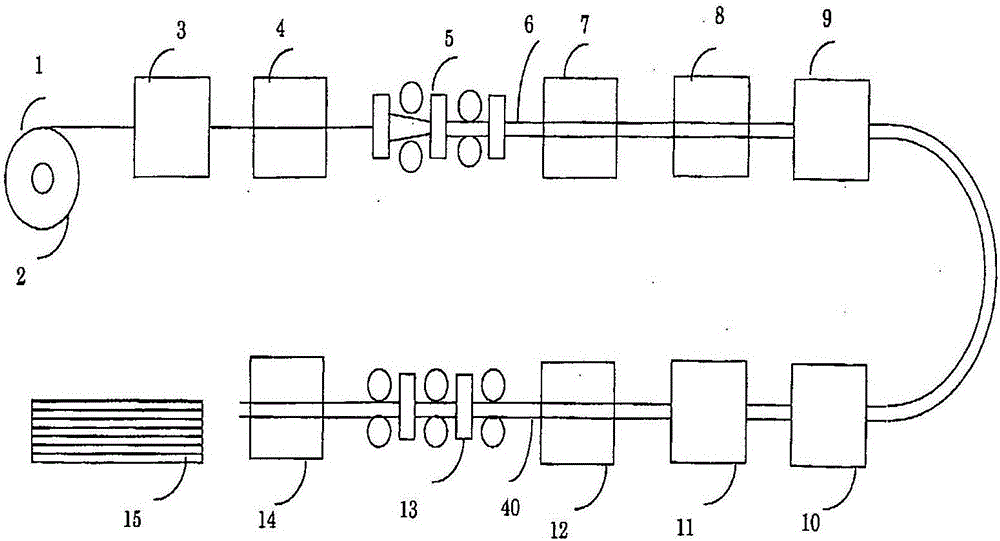

[0076] Aluminum is used as the sprayed metal. A long rolled steel plate with a thickness of 1.2 mm and a width of 59.5 mm is set on figure 1 In the production line shown, the inner surface is shot blasted by the shot blasting device, and then the sprayed metal layer is formed on the inner surface by the thermal spraying device. In addition, after the hot-dip galvanizing device, the aluminum is sprayed by the surface spraying device.

[0077] In the present invention, conditions such as zinc surface temperature (normal temperature to 450° C.), linear velocity (0 to 400 m / min), and spraying angle (0 to 90°) during thermal spraying can be appropriately combined. At the same time, the combination concentration and distribution of aluminum can be adjusted by adjusting the amount of sprayed aluminum.

[0078] Figure 5 A comparison of the appearance of the steel pipe manufactured in Example 1 and the steel pipe manufactured by the hot-dip plating method as a conventional example ...

Embodiment 2

[0083] Aluminum is used as the sprayed metal, and a long rolled steel plate with a thickness of 1.2mm and a width of 59.5mm is installed on the figure 1 In the production line shown, the inner surface is shot blasted by a shot blasting device, and then a sprayed metal layer is formed on the inner surface by a thermal spraying device. In addition, after the hot-dip galvanizing, the aluminum is sprayed by the surface spraying equipment.

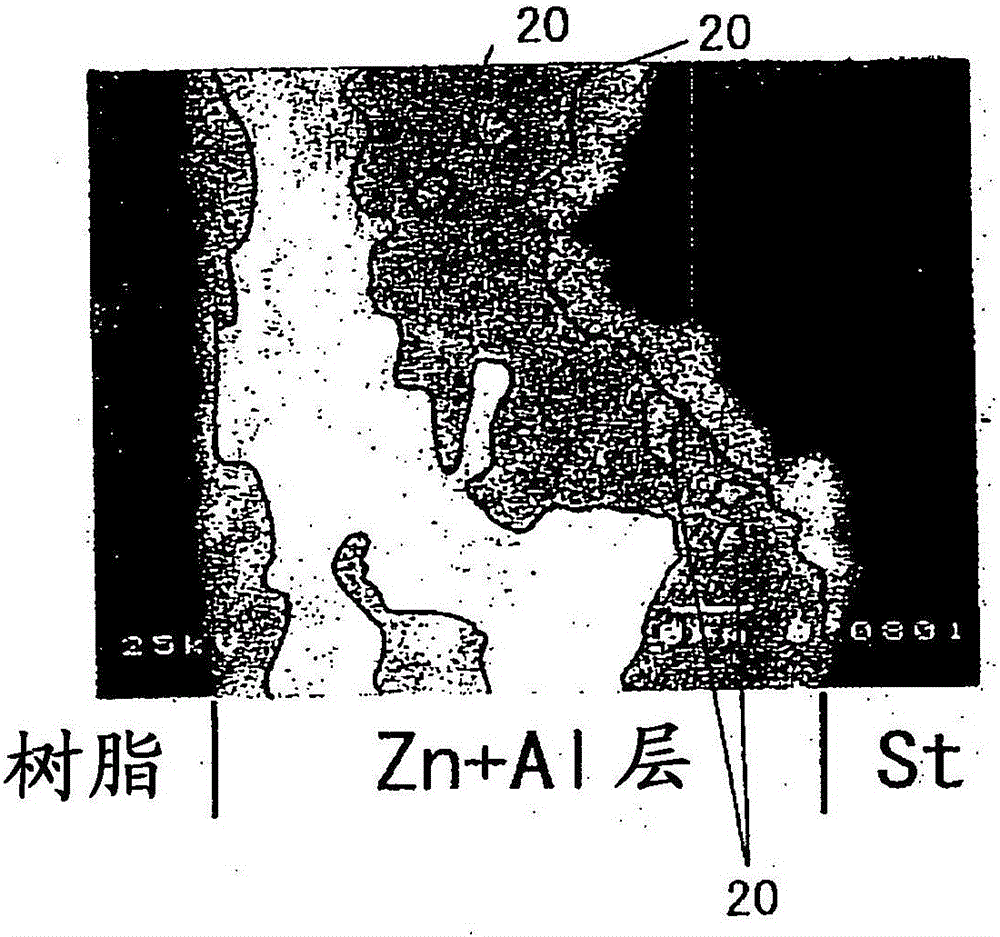

[0084] The appearance photograph of the obtained section is shown in Figure 6 (a), the process of measuring the element distribution of its cross-section by EPMA is shown in Figure 6 (b). Such as Figure 6 As shown in (a), in the steel pipe based on the present example, the feature that the sprayed metal is discretely distributed in the form of fine islands in the matrix metal can be seen. It can be seen that the blackened aluminum is finely and discretely distributed in the whitish zinc matrix. Additionally, if Figure 6 As shown in (b...

Embodiment 3

[0086] Aluminum is used as the sprayed metal, and a long rolled steel plate with a thickness of 1.2mm and a width of 59.5mm is installed on the figure 1 In the production line shown, the inner surface is shot blasted by a shot blasting device, and then a sprayed metal layer is formed on the inner surface by a thermal spraying device. In addition, after the hot-dip galvanizing device, the thermal spraying of aluminum is performed by the surface spraying device. In this example, the galvanized surface temperature was about 400°C, and aluminum was sprayed at 15 g / min at a spraying angle of 90° in a low-speed production of about 20 m / min. The contact portion between zinc and sprayed aluminum dissolves, which promotes the combination with aluminum, and the distribution of the surface is an aluminum layer, the middle is a zinc-aluminum layer, and the inner layer is a zinc layer. This structure can also be realized in medium and high-speed production based on a series of correlation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com