Smoke SCR denitration system for fluidized fuel gas kiln

A gas furnace and denitrification technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems that the amount of catalyst cannot be adjusted in real time, the catalytic activity is difficult to achieve, and the volume of the denitrification reactor is large, so as to achieve equipment cost and Low operation and maintenance costs, real-time adjustable dosage, and the effect of reducing space volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

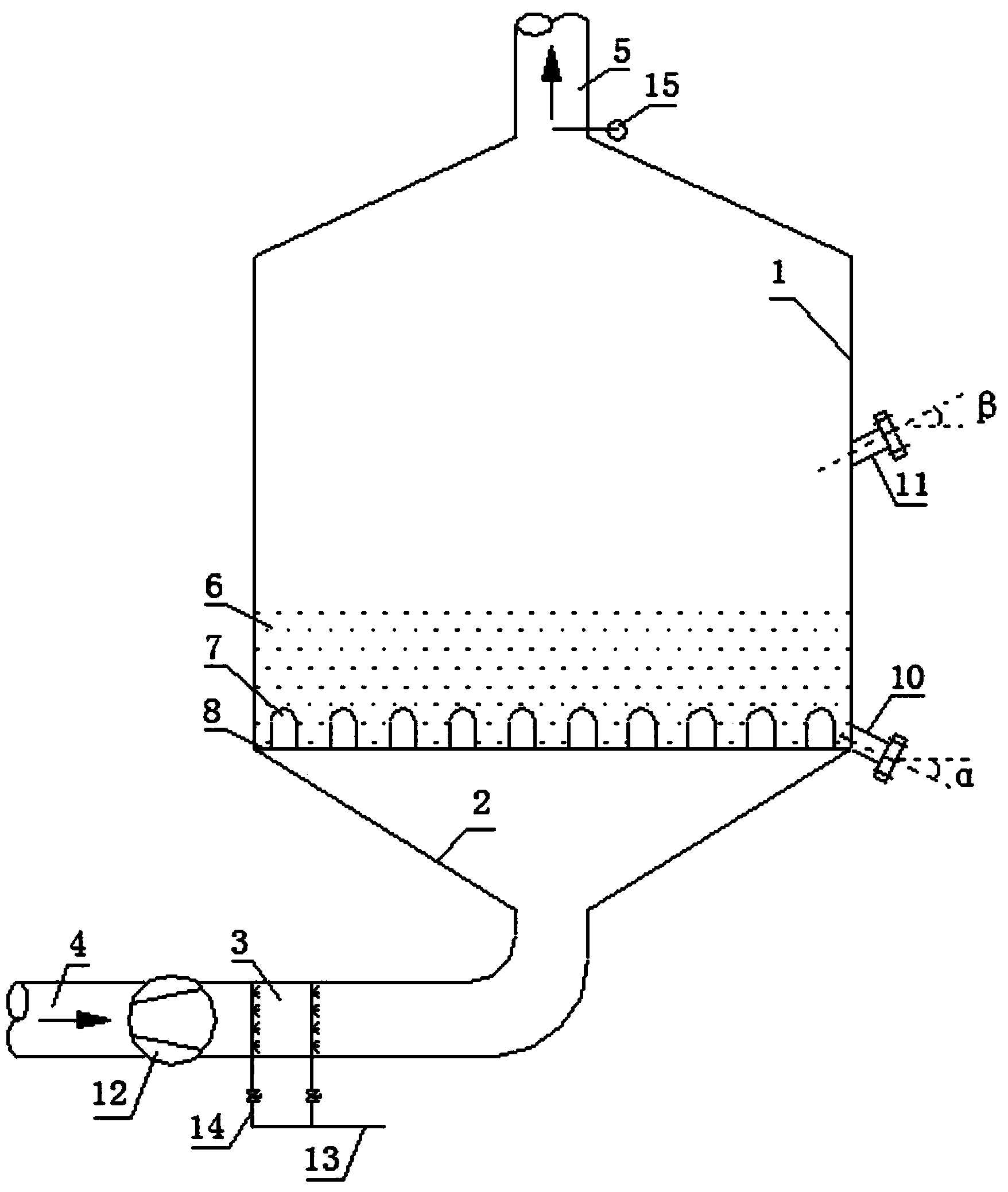

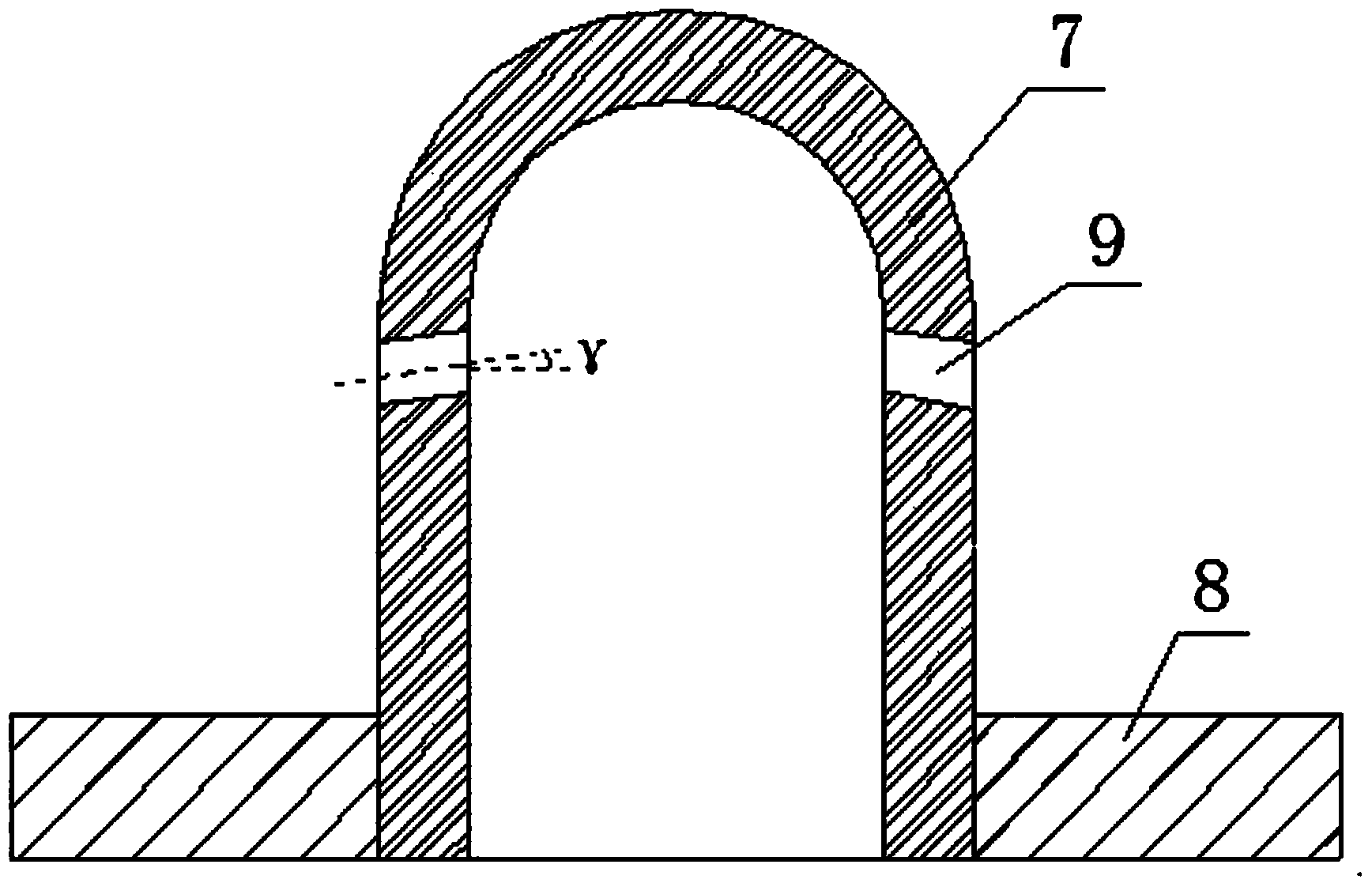

[0049] see figure 1 , The system of the present invention is mainly composed of a reaction chamber 1 and a mixing chamber 2 arranged up and down. An air distribution plate 8 is arranged at the lower part of the upper reaction chamber 1 , that is, between the reaction chamber 1 and the mixing chamber 2 , and catalyst particles 6 are accumulated on the air distribution plate 8 .

[0050] In order to control the quantity and quality of the catalyst particles 6 in real time, the side wall of the reaction chamber 1 may be provided with a particle discharge port 10 and a particle replenishment port 11 . The particle discharge port 10 is set at the bottom of the reaction chamber, at the same height as the air distribution plate; the particle replenishment port 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com