High-temperature superconducting binary current lead based on conduction cooling

A binary current lead and high-temperature superconducting technology, which is applied in the direction of superconducting magnets/coils, circuits, electrical components, etc., can solve the application of limited conduction binary current leads, lead wires cannot be flexibly wired and installed, and internal space is crowded, etc. problems, to achieve the effect of fast heat dissipation, excellent thermal conductivity and electrical insulation performance, and reduce heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

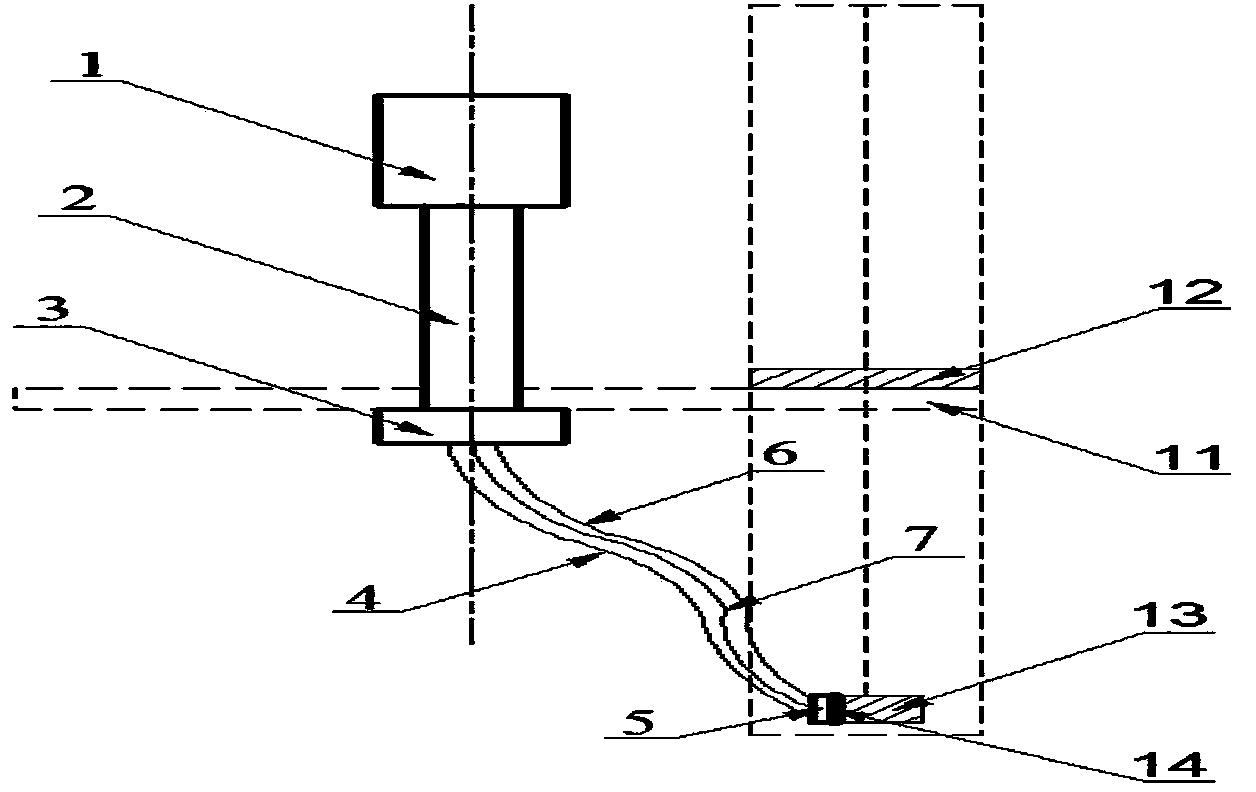

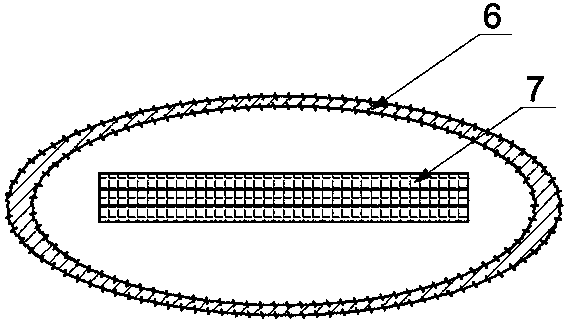

[0026] The high-temperature superconducting binary current leads of this scheme, such as figure 1 As shown, it is composed of room temperature copper joint 1, copper lead section 2, connecting transition section 3, superconducting combination section 4 and low temperature copper joint 5, and its cooling method is realized by conduction cooling of a two-stage refrigerator. combine figure 1 and figure 2 It can be seen that the current lead superconducting combined section 4 is mainly composed of copper braid 6 and superconducting strip 7 .

[0027] Such as figure 2 As shown, the superconducting strip 7 is installed inside the copper braid 6, and its quantity can be determined according to the user's current demand.

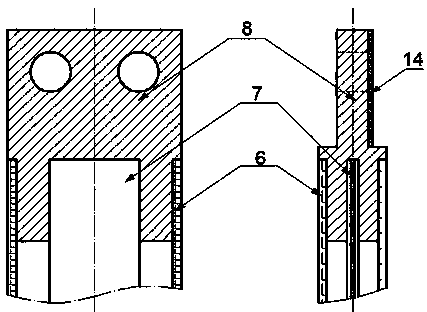

[0028] Such as image 3 As shown, the processing of the upper and lower end joints 8 of the superconducting combined section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com