High temperature resistant pre-crosslinked granular profile control agent and preparation method and application thereof

A technology of pre-crosslinking and profile control agent, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc. Solve problems such as limited salt performance, achieve good elasticity and expansion performance, good effect of increasing oil and reducing water, and improve water flooding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Preparation of production equipment: design and manufacture production equipment for one production of 2 tons of pre-crosslinked profile control agent.

[0053] Mixing tank: vertical cylindrical mixing tank with a bottom cross-sectional area of 3m 2 , with a height of 1m and a full load of 3m 3 . Open, normal temperature and pressure.

[0054] The liquid storage tank is 1.985m long, 0.99m wide, 0.75m high, and has a cross-sectional area of 1.965m 2 , volume 1.5m 3 , The stock solution is used to dilute the water glass. A centrifugal pump can be used to directly add diluted water glass to the mixing tank.

[0055] 2. The production process is as follows:

[0056] 1) Accurately weigh 400 kg of acrylamide monomer (16 bags), add 766 kg of water (liquid height 25.5 cm), and stir until the acrylamide monomer is completely dissolved.

[0057] 2) Accurately measure 40 kg of acrylic acid solution (concentration of stock solution) and pour it into the mixing tank an...

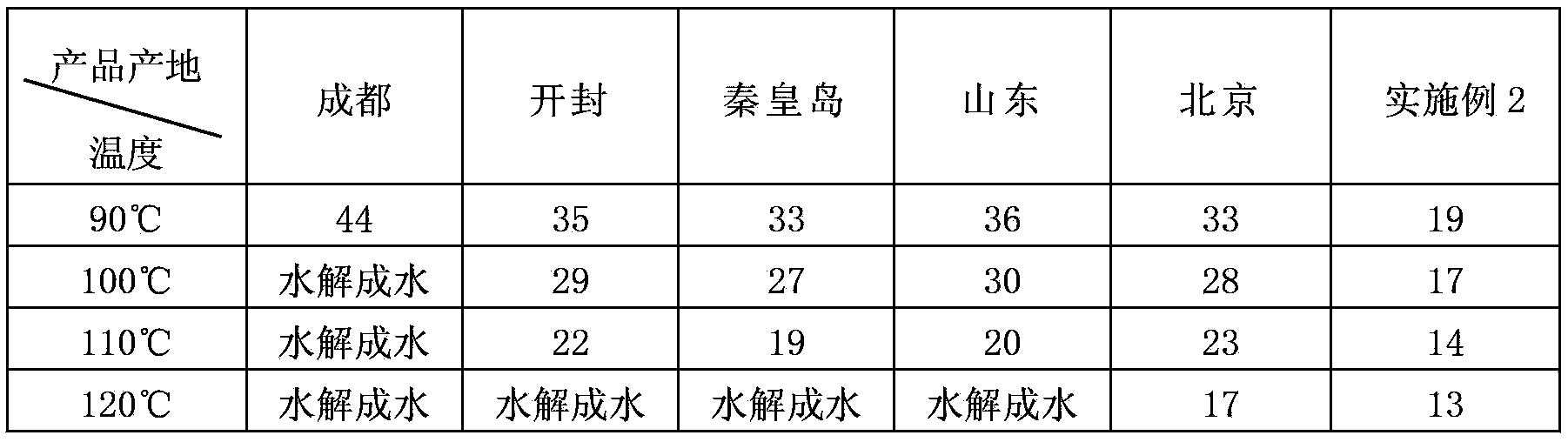

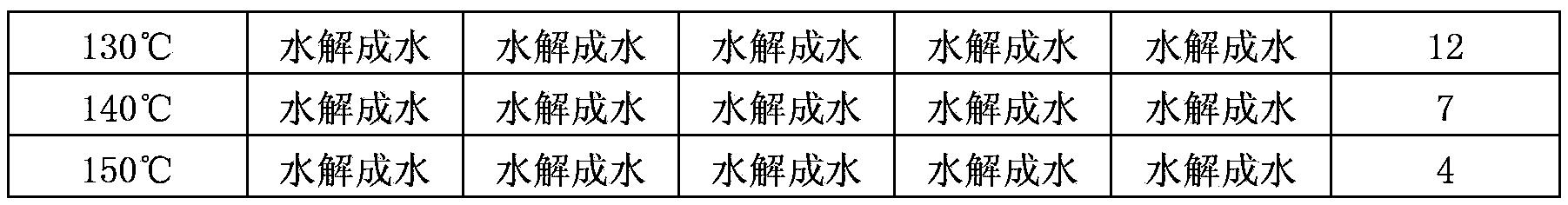

Embodiment 2

[0070] 1. Preparation of production equipment: design and manufacture production equipment for one production of 2 tons of pre-crosslinked profile control agent.

[0071] Mixing tank: vertical cylindrical mixing tank with a bottom cross-sectional area of 3m 2 , with a height of 1m and a full load of 3m 3 . Open, normal temperature and pressure.

[0072] The liquid storage tank is 1.985m long, 0.99m wide, 0.75m high, and has a cross-sectional area of 1.965m 2 , volume 1.5m 3 , The stock solution is used to dilute the water glass. A centrifugal pump can be used to directly add diluted water glass to the mixing tank.

[0073] 2. The production process is as follows:

[0074] 1) Accurately weigh 500 kg of acrylamide monomer (20 bags), add 766 kg of water (liquid height 25.5 cm), and stir until the acrylamide monomer is completely dissolved.

[0075] 2) Accurately measure 40 kg of acrylic acid solution (concentration of stock solution) and pour it into the mixing tank an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com