Polishing and cleaning tool for inner holes of tube plates of condensers

A technology of condenser tubes and inner holes, which is applied in the direction of manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., which can solve the problems of large differences in the cleanliness of the tube holes and slow speed of the tube holes, and achieve improved Labor efficiency and safety factor, fast filling speed, clean and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

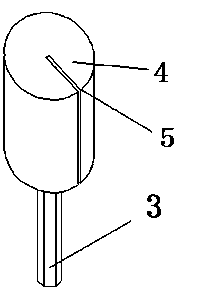

[0014] Such as figure 1 , 2 As shown, a grinding and cleaning tool for the inner hole of a condenser tube plate of the present invention includes an electric drill 1 with a drill chuck 2, the drill chuck 2 holds a grinding handle 3, and the end of the grinding handle 3 is provided with a cylindrical The grinding head 4 is provided with an axial card groove 5 on the grinding head 4, and the card groove 5 is opened on the top, bottom and outer peripheral surface of the grinding head 4, and sandpaper is wound on the outer peripheral surface of the grinding head 4, and the sandpaper The end is inserted into the card slot 5.

[0015] Grinding head 4 diameters can subtract 2~3mm processing according to the size of tube hole diameter, so that winding sandpaper, length should be equated with the tube hole length being polished. The cross-section of the grinding handle 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com