Direct methanol fuel cell with alloy-TiO2 nanotube/Ti anode and preparation method thereof

A methanol fuel cell and nanotube technology, applied in fuel cells, battery electrodes, circuits, etc., to improve the ability to resist CO poisoning, improve battery performance, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

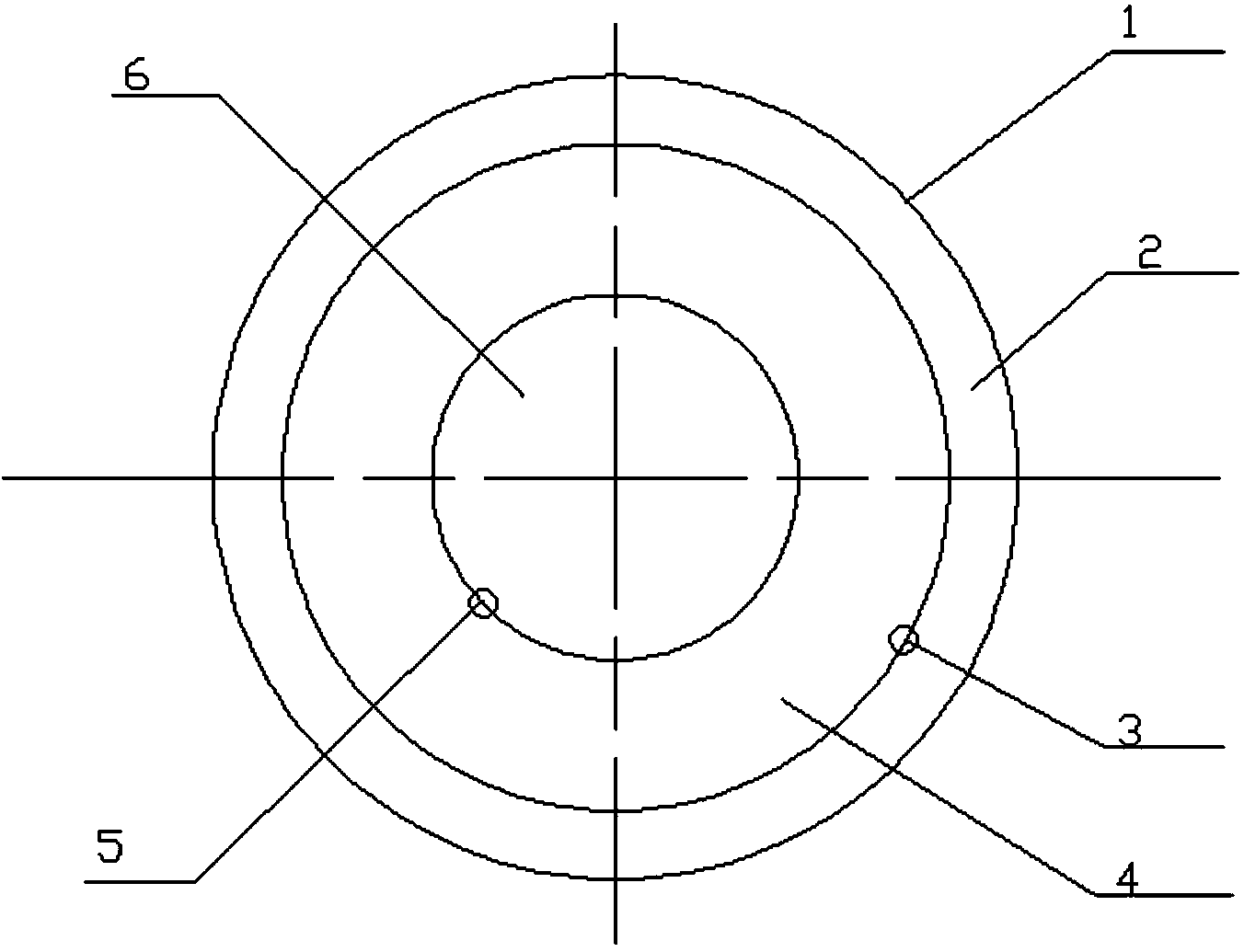

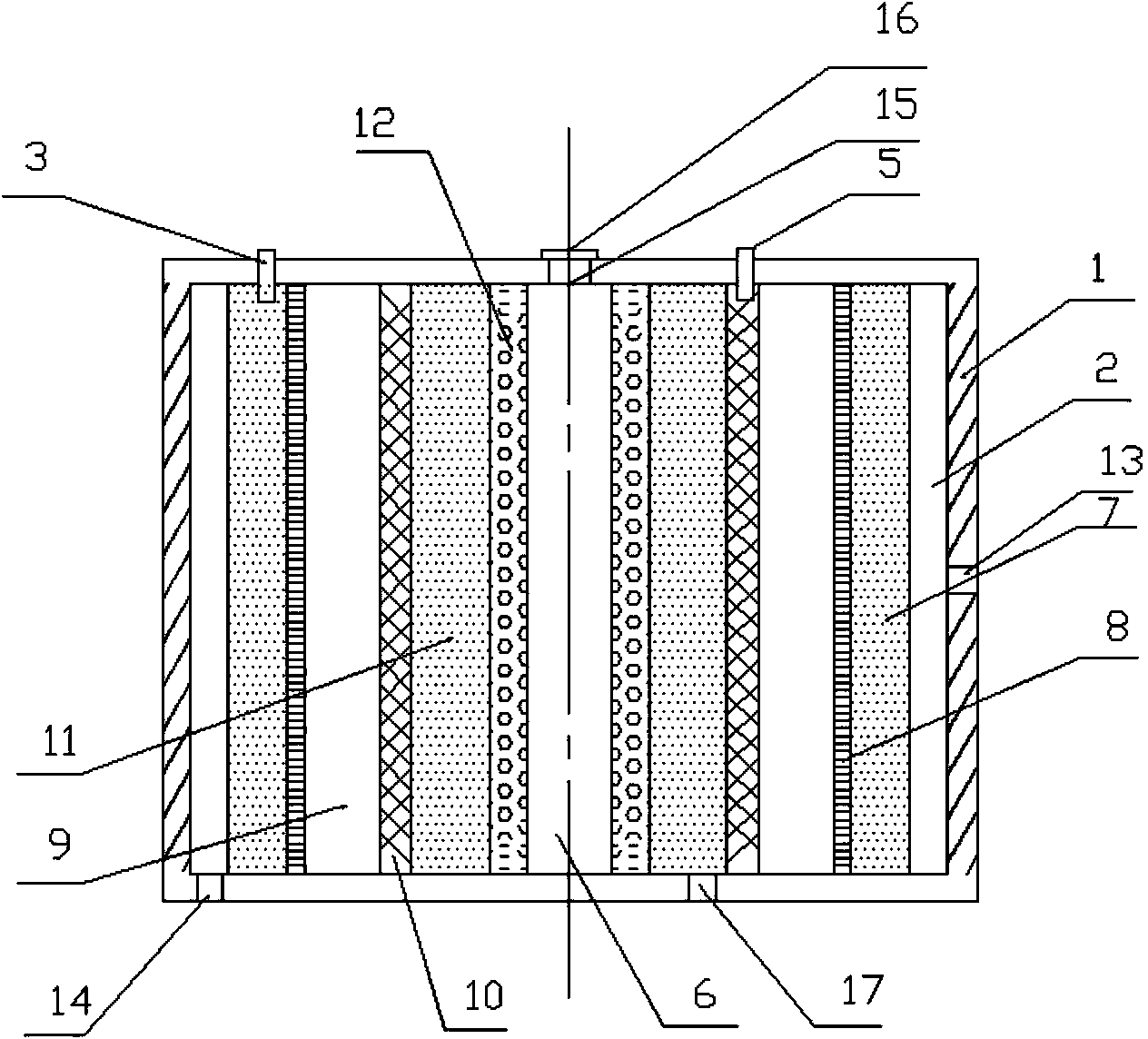

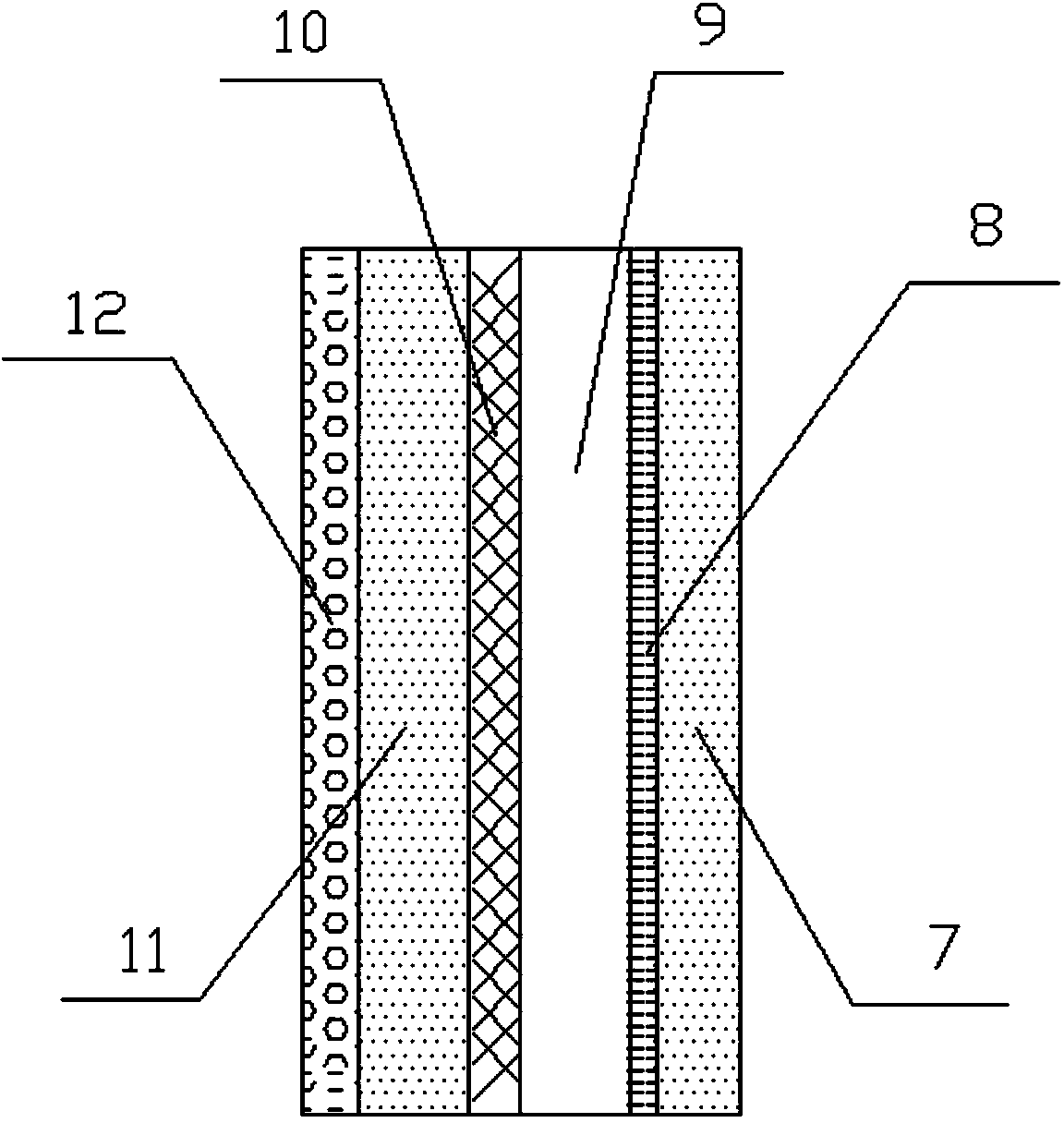

[0027] Alloy-TiO 2 The nanotube / Ti anode direct methanol fuel cell includes a battery casing 1, a membrane electrode 4 is arranged in the battery casing, an air chamber 2 is formed between the casing and the membrane electrode, an electrolyte chamber 6 is arranged inside the membrane electrode, and the membrane electrode is from outside to inside. Cathode diffusion layer 7, cathode catalyst layer 8, Nafion membrane 9, porous titanium tube 10, TiO 2 The nanotube 11, the nano alloy layer 12 deposited by electroplating, the cathode diffusion layer and the battery casing are connected by welding points to be set as the cathode output end 3, the anode diffusion layer and the battery casing are connected by welding points to be set as the anode output end 5, and the electrolyte of the casing The chamber part is provided with feeding hole 15, the feeding sealing cover 16, the air chamber part of the casing is provided with air circulation hole 13, the bottom of the air chamber of the...

Embodiment 2

[0044] in TiO 2 The nano-alloy deposited by electroplating on the inner surface of the nanotube / Ti is PdAg alloy.

[0045] The composition of the plating solution:

[0046] AgNO 3 0.01mol / L

[0047] Pd(NO) 2 0.01mol / L

[0048] h 3 BO 3 20g / L

[0049] pH: 4.4

[0050] T: room temperature

[0051] Current density: 5 mA / cm 2

[0052] t: 120min

[0053] After electroplating, wash with deionized water and dry to obtain PdAg-TiO 2 Nanotube / Ti anode. Others are the same as embodiment 1.

Embodiment 3

[0055] in TiO 2 The inner surface of the nanotube / Ti is electroplated and deposited nano-alloy is RuNi alloy.

[0056] The composition of the plating solution:

[0057] NiSO 4 ·6H 2 O 250 g / L

[0058] RuCl 3 1g / L

[0059] h 3 BO 3 20g / L

[0060] pH 4.4

[0061] T room temperature

[0062] Current density: 5 mA / cm 2

[0063] t 120 min

[0064] After electroplating, wash with deionized water and dry to get RuNi-TiO 2 Nanotube / Ti anode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com