Tension resisting and twisting resisting combined shock isolation device based on linear guide rail

A linear guideway, anti-torsion technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc. The problem of low strength of the seismic support has achieved the effect of large range of seismic isolation requirements, large stiffness adjustment range, and remarkable seismic isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

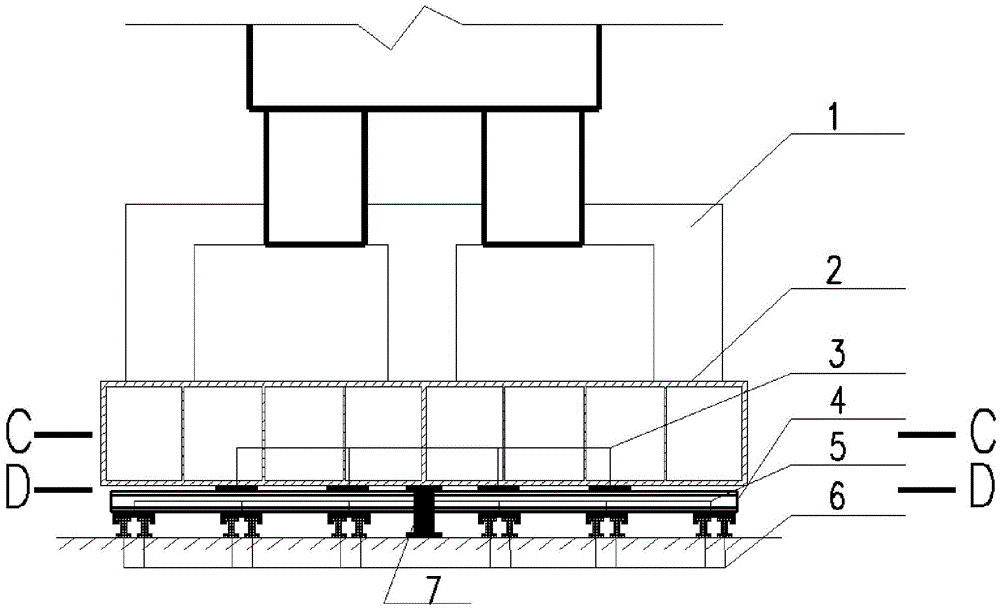

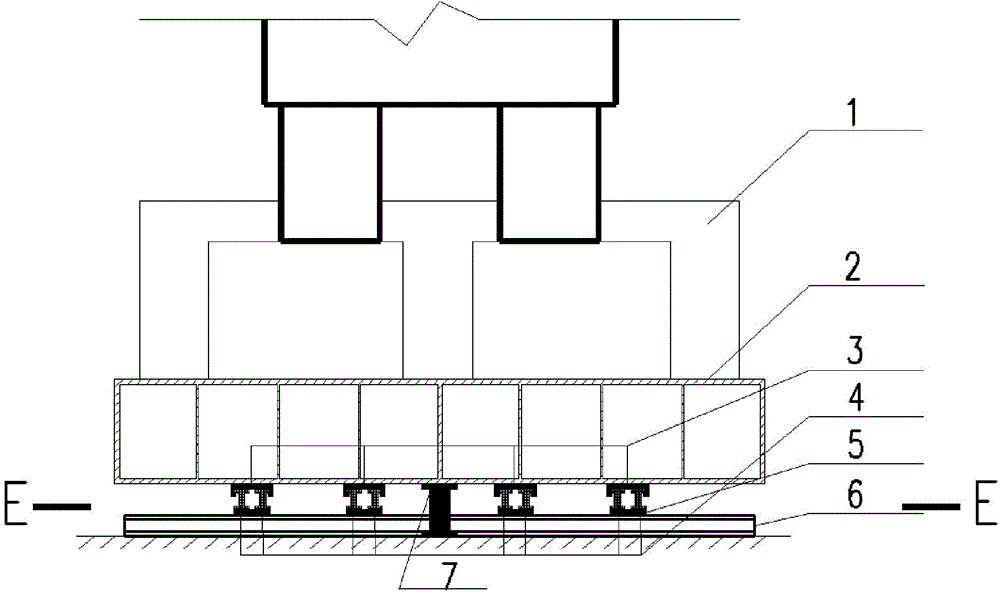

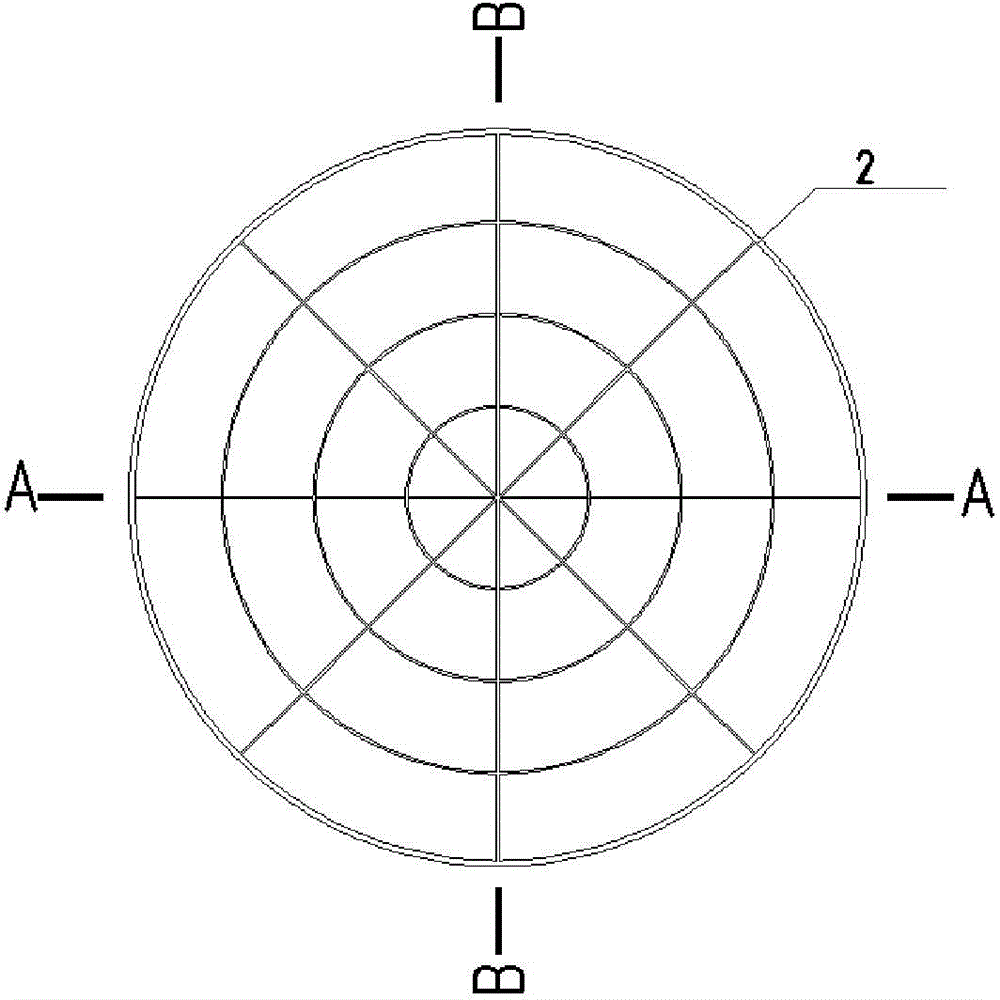

[0030] In specific implementation, first determine the section size of the rigid isolation base 2 according to the load of the upper high-flexibility equipment 1; determine the bottom longitudinal vibration-isolation linear guide according to the sum of the load of the upper high-flexibility equipment 1 and the self-weight load of the rigid isolation base 2 6. The cross-sectional size and quantity of the bottom horizontal vibration-isolation linear guide rail 4, the horizontal limit slider 3, and the longitudinal limit slider 5; according to the vibration isolation effect to be achieved, select the rubber bearing 5 that can provide the horizontal rigidity of the structure. ; According to the displacement of the shock-isolation layer, determine the distance between the shock-isolation support 5 and the linear guide rail to avoid collision between the two, determine the edge distance between the limit slider and the linear guide rail, and avoid the limit slider from sliding out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com