Printing and dyeing technology of purified cotton home textile fabric

A printing and dyeing process and home textile technology, which is applied in the field of textile printing and dyeing, can solve the problems of unsatisfactory hand feeling, pilling, and strength and other physical and chemical indicators, so as to ensure the performance of anti-pilling, guarantee the weft breaking strength, The effect of reducing the degree of fibrillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1. Optimization of the boiling and bleaching step

[0047] In this embodiment, a scouring and bleaching step is provided, and the scouring and bleaching step includes scouring and bleaching, wherein,

[0048] The working liquid formula of described scouring step is as follows:

[0049] Each 1 liter of scouring working solution contains:

[0050] NaOH 30~50g

[0051] Complexing agent Sirrix 2UD Liq 1~5g

[0052] Alkali-resistant scouring agent 2137 2~10g;

[0053] The finishing condition of the scouring step is 90-110°C, 20-60 minutes;

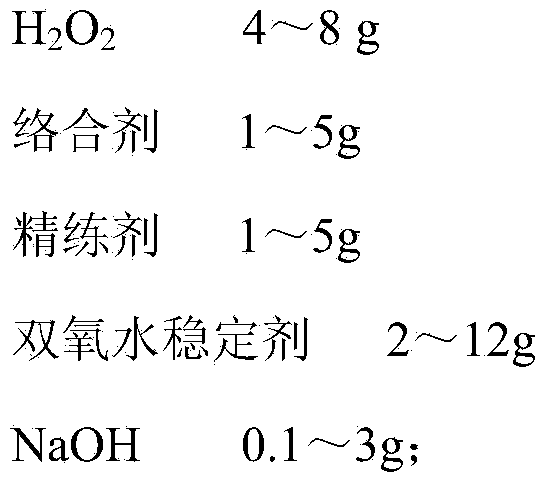

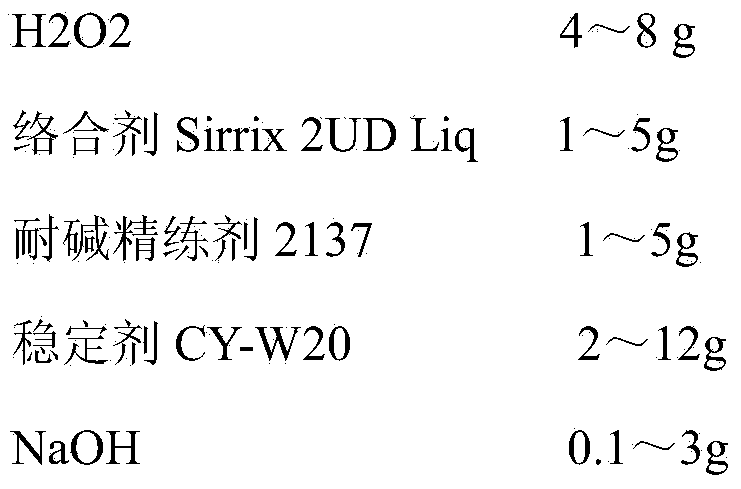

[0054] The working solution formula of described bleaching step is as follows:

[0055] Each 1 liter of bleach working solution contains:

[0056]

[0057] The finishing condition of the bleaching step is 90-110° C. for 20-60 minutes.

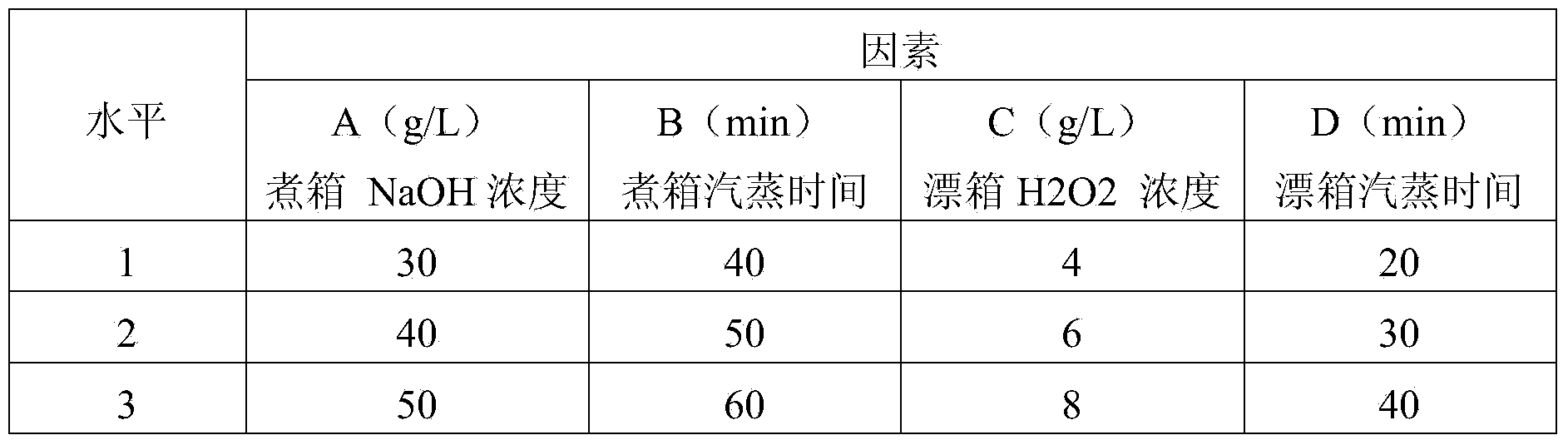

[0058] In order to study the influence of the above-mentioned parameters on the weft breaking strength of semi-finished products (after cooking and bleaching) and the weft breaking st...

Embodiment 2

[0080] Example 2. Optimization of the biopolishing step

[0081] In this embodiment, a biopolishing step is provided, and the working fluid formula of the biopolishing step is as follows:

[0082] Tencel decomposing enzyme Sincell 700 0.1~1%, owf%

[0083] Acetic acid 0.1~1%, owf%

[0084] The finishing condition of the biological polishing step is 6 times at 30-70°C.

[0085] The applicant has done test screening to a large amount of polishing enzyme art from several major aspects: a) the concentration of polishing enzyme b) the pH value of polishing process c) the temperature of polishing process, d) the time (that is, the number of passes) of polishing process f ) The weft fracture strength of the cloth determined by the polishing process g) The fluff of the cloth surface determined by the polishing process. The optimization process that finally determines the polishing step is as follows:

[0086] The working fluid formula of described biological polishing step is as f...

Embodiment 3

[0090] Example 3. Optimization of softening step

[0091] Soft step is provided in the present embodiment, and the formula of working liquid of described soft step is as follows:

[0092] Each liter of finishing working solution contains:

[0093] Quaternary ammonium softener Skysoft PQ20 5~20g

[0094] Hydrophilic silicone softener Skysoft ST50 2~10g

[0095] Buffer JY-1 2g

[0096] The softening step is completed on a softening finishing machine, and the process conditions are 120-170° C., 40-80 m / min.

[0097] The applicant has tested and screened a large number of softeners in several aspects: a) the ratio of two softeners b) the finishing temperature c) the speed of finishing the vehicle, d) the weft breaking strength of the fabric after finishing f) Weft breaking strength after finishing g) Hand feeling of cloth surface after finishing. The optimization process that finally determines the softening step is as follows:

[0098] The working liquid formula of describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com