Method for preparing natural gas from yellow phosphorus tail gas and production device using method

A technology of yellow phosphorus tail gas and natural gas, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of flue gas polluting the atmosphere, affecting economic benefits, and difficult processes, so as to reduce costs, improve economic benefits, and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

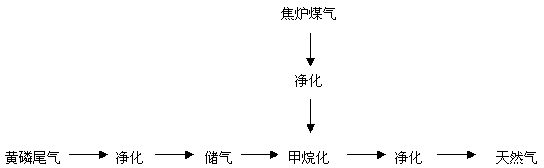

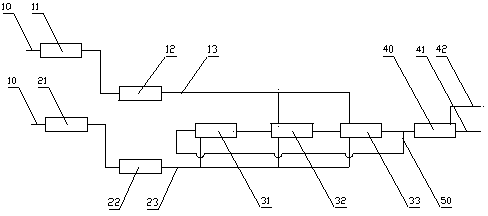

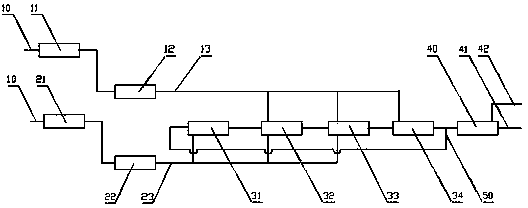

[0014] see figure 1 , the present invention provides that yellow phosphorus tail gas and coke oven gas are used as raw material gas, which are fed into the methanation device together, relying on hydrogen in the raw material gas and carbon monoxide and carbon dioxide in the raw material gas to carry out sufficient methanation reaction, by controlling the yellow phosphorus The ratio of tail gas and coke oven gas controls the ratio of hydrogen, carbon monoxide and carbon dioxide in the reaction system, so that the contents of hydrogen, carbon monoxide and carbon dioxide in the reacted gas all meet the requirements of natural gas.

[0015] Because the content of the gas components participating in the reaction in the methanation unit is very low, the impact on the methanation reaction is small, and it can usually be ignored in the calculation. Therefore, the reaction system is controlled by controlling the ratio of yellow phosphorus tail gas and coke oven gas. The way in which th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com