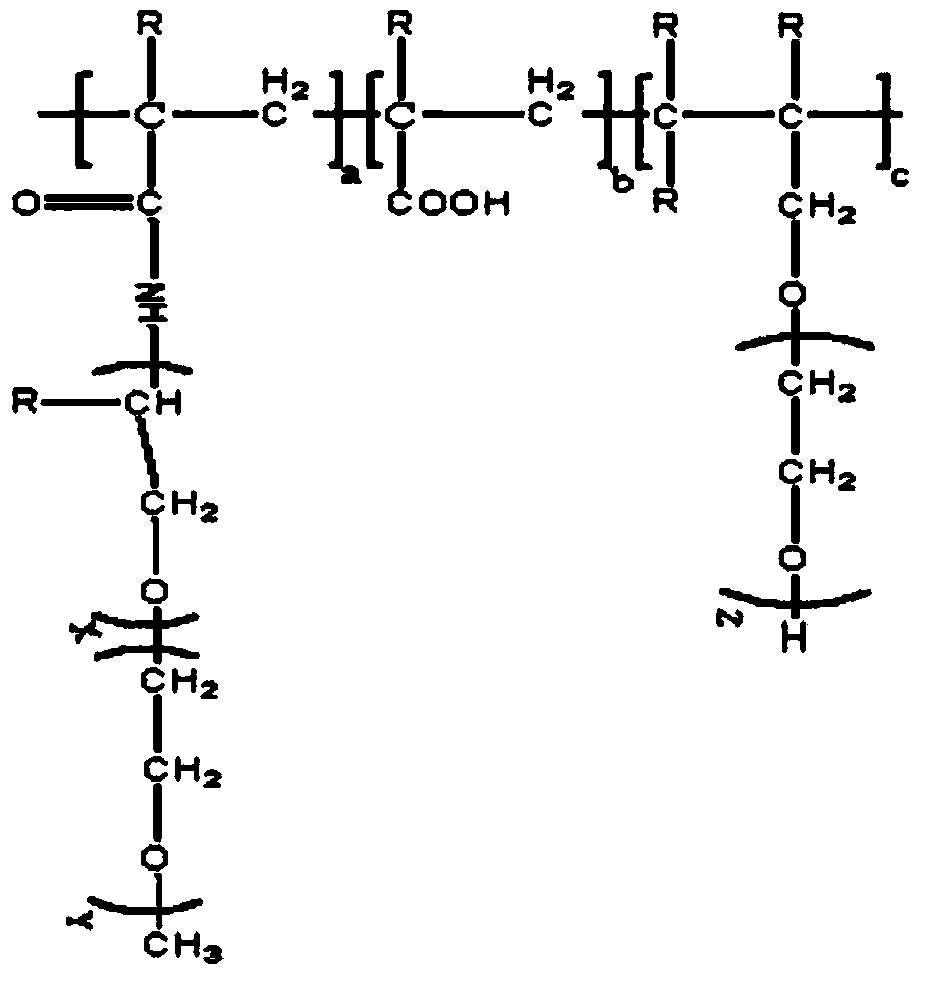

Polyether-amide type polycarboxylic high-efficiency water reducer and preparation method thereof

The technology of amide type polycarboxylic acid and high-efficiency water reducing agent is applied in the field of concrete admixture, which can solve the problem of high price of amide, and achieve the effects of stable product performance, environmental safety and environmental protection, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

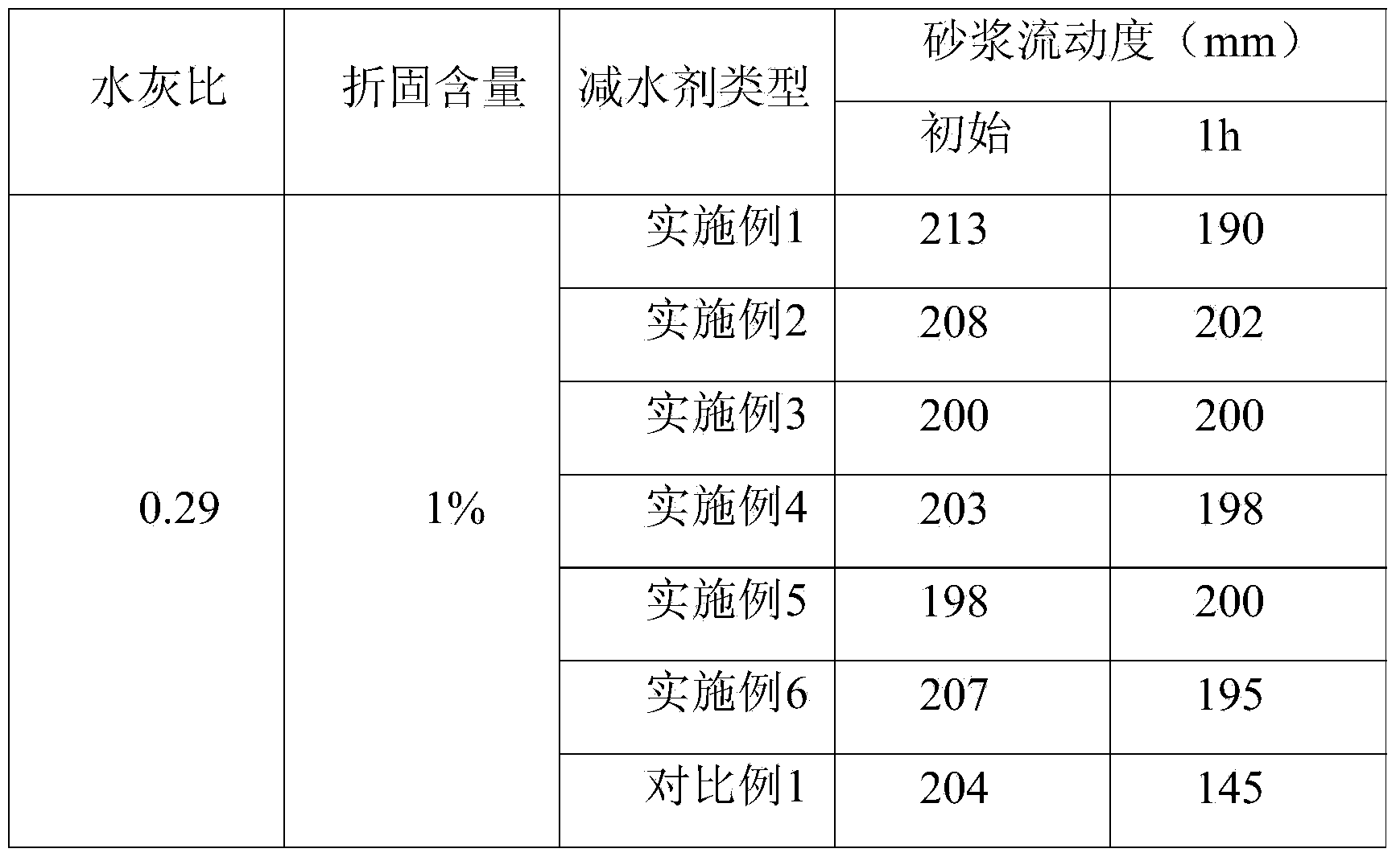

Examples

Embodiment 1

[0028] The preparation method of a polyether-amide type polycarboxylic acid superplasticizer of this embodiment includes the following operation steps:

[0029] (1) Add 80 parts by mass of polyetheramine with a weight average molecular weight of 2000 to the reaction kettle, add 2 parts by mass of potassium carbonate under stirring at 0°C, and 4 parts by mass of methacrylic chloride dropwise, and the dropping time is 10 minutes After the dripping, maintain 0°C for 2 hours to obtain a polyetheramine monomer containing an amide structure;

[0030] (2) Add 100 parts by mass of deionized water and 204 parts by mass of isopentenol polyoxyethylene ether with a weight average molecular weight of 2000 to the reactor of step (1), heat up to 70°C, and add to the reactor 2 parts by mass of hydrogen peroxide, and dropwise add a mixed solution consisting of 20 parts by mass of acrylic acid, 4 parts by mass of thioglycolic acid, 0.4 parts by mass of ascorbic acid, and 350 parts by mass of deioniz...

Embodiment 2

[0032] The preparation method of a polyether-amide type polycarboxylic acid superplasticizer of this embodiment includes the following operation steps:

[0033] (1) Add 133 parts by mass of polyetheramine with a weight-average molecular weight of 600 to the reactor, add 3.5 parts by mass of potassium carbonate under stirring at 2°C, and add 7 parts by mass of methacrylic chloride dropwise, and the dropping time is 15 minutes After the dripping, maintain 2°C for 2 hours to obtain a polyetheramine monomer containing an amide structure;

[0034] (2) Add 100 parts by mass of deionized water and 145 parts by mass of prenol polyoxyethylene ether with a weight average molecular weight of 1600 to the reactor of (1), increase the temperature to 55°C, and add 2 to the reactor. Parts by mass of hydrogen peroxide, and dropwise add a mixed solution consisting of 20 parts by mass of acrylic acid, 4 parts by mass of thioglycolic acid, 0.4 parts by mass of ascorbic acid, and 360 parts by mass of d...

Embodiment 3

[0036] The preparation method of a polyether-amide type polycarboxylic acid superplasticizer of this embodiment includes the following operation steps:

[0037] (1) Put 187 parts by mass of polyetheramine with a weight average molecular weight of 1500 into the reactor, add 5 parts by mass of potassium carbonate under stirring at 5°C, and add 10 parts by mass of methacrylic chloride dropwise, and the dropping time is 20 minutes After the dropping, maintain 5°C for 2 hours to obtain a polyetheramine monomer containing an amide structure;

[0038] (2) Add 100 parts by mass of deionized water and 87 parts by mass of prenol polyoxyethylene ether with a weight average molecular weight of 2000 to the reactor of (1), increase the temperature to 75°C, and add 2 to the reactor. Parts by mass of hydrogen peroxide, and dropwise add a mixed solution consisting of 20 parts by mass of acrylic acid, 4 parts by mass of thioglycolic acid, 0.4 parts by mass of ascorbic acid, and 360 parts by mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com