Bottle automatic inspection production line

An automatic detection and production line technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as inflow of unqualified products, consumer losses, hazards, etc., achieve orderly production, convenient production, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

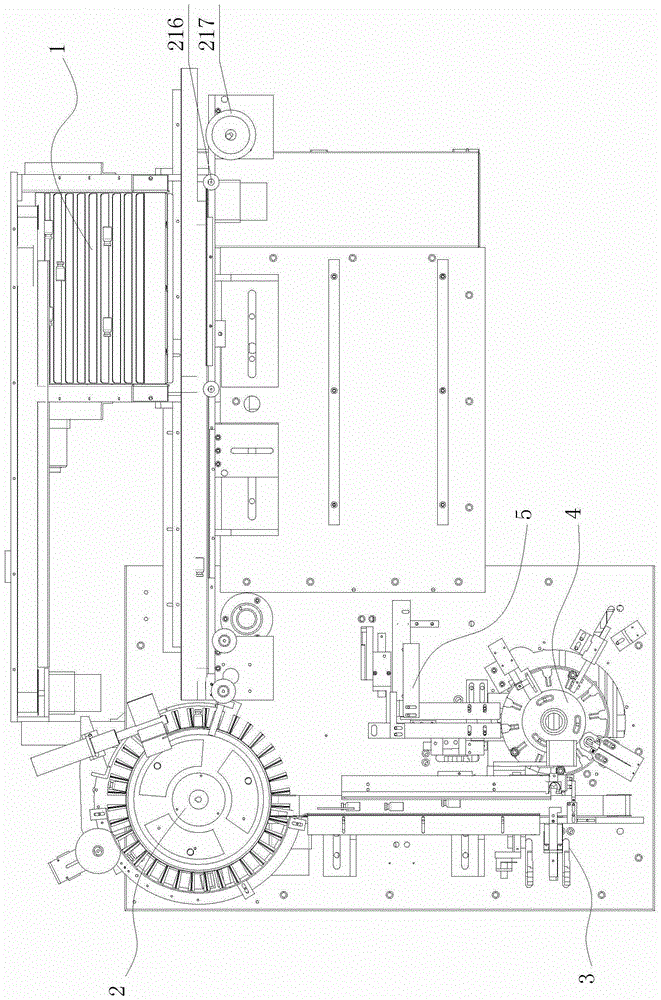

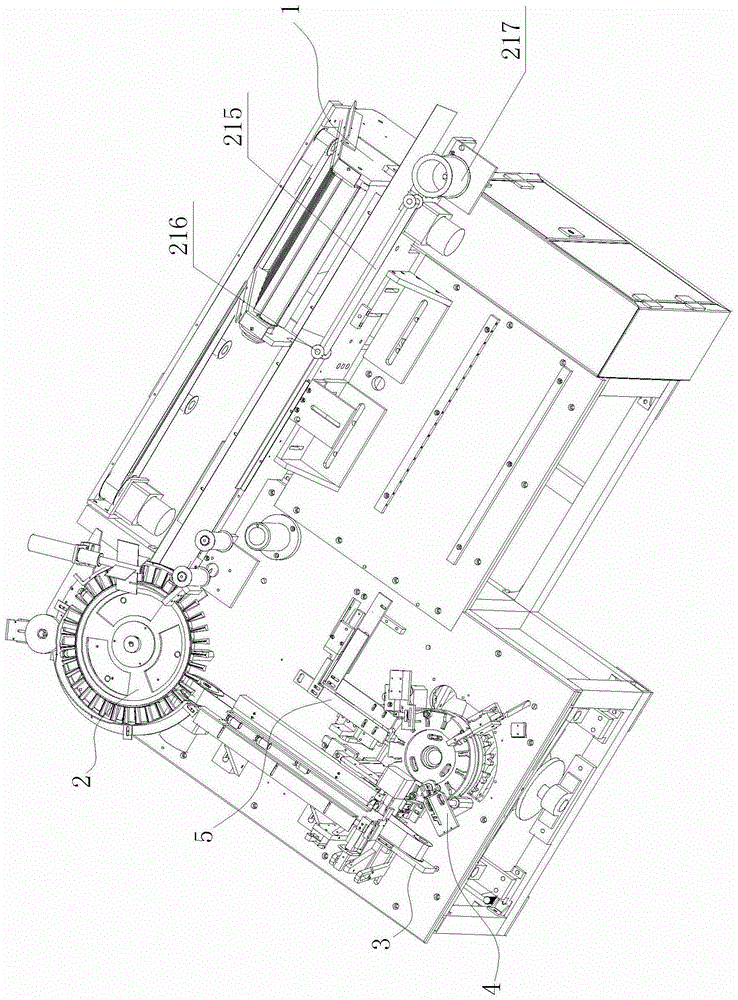

[0044] See figure 1 and figure 2 , an automatic detection production line for bottles, which has a frame on which a conveying device 1, an automatic sorting device 2, an automatic bottle unscrambling and vertical bottle device 3, a precision inspection device 4, and a crack and broken bottle detection device 5 are arranged in sequence. ;

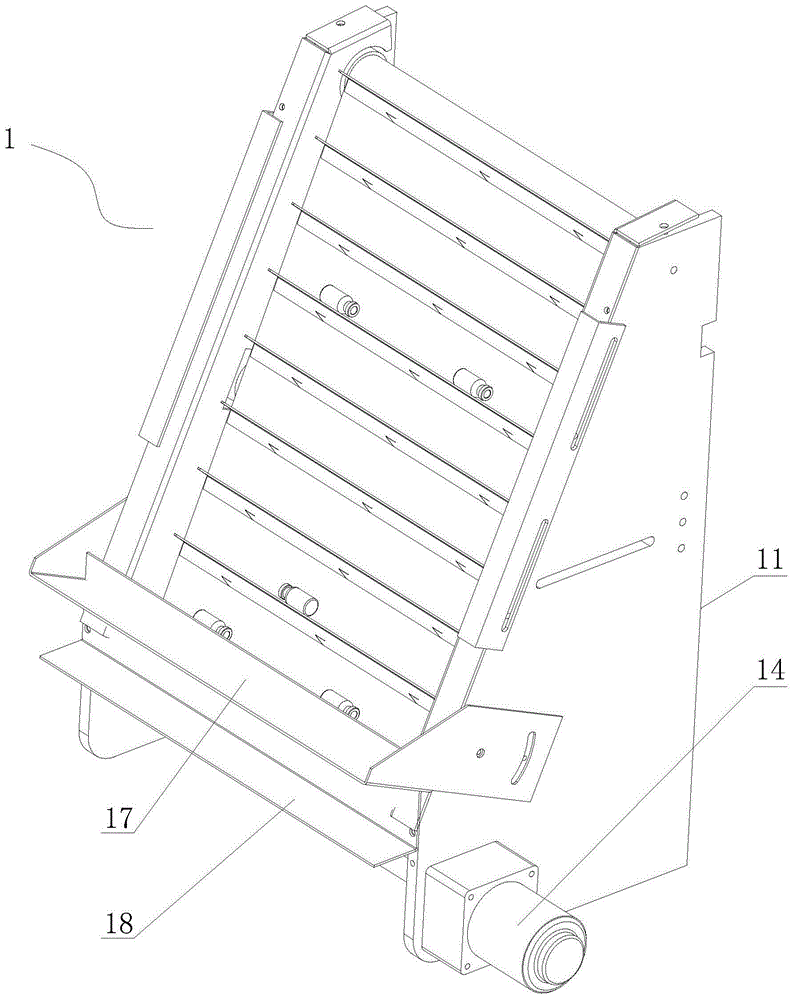

[0045] See Figure 3 to Figure 5 , conveying device 1 has casing 11, main bearing 12, first auxiliary bearing 13, conveying motor 14 and belt 15; 11 bottom; the first auxiliary bearing 13 is arranged on the top of the casing 11; the rotating shaft of the conveying motor 14 is fixedly connected with the main bearing 12; the belt 15 is wound on the main bearing 12 and the first auxiliary bearing 13; Belt buckle 16; the angle α between the connection line between the main bearing 12 and the first auxiliary bearing 13 and the bottom of the casing 11 is less than 90°; the angle β between the belt buckle 16 and the surface of the belt 15 is le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com