Offline low-emissivity glass coated film system

A technology of low-emissivity glass and film system, which is applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problems of high reflectivity and angle color tend to be reddish, and achieve small angle color deviation , Excellent wear resistance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

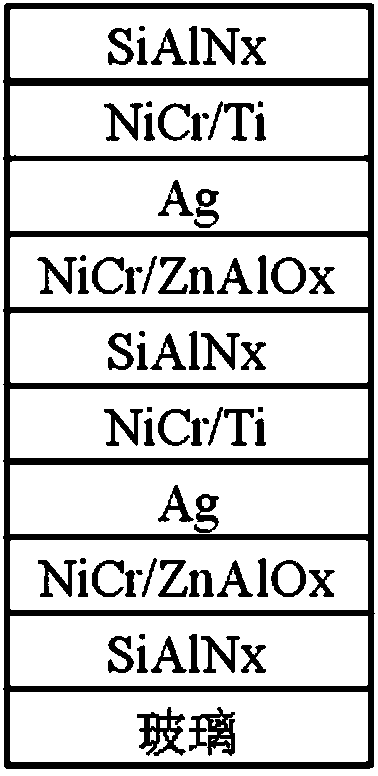

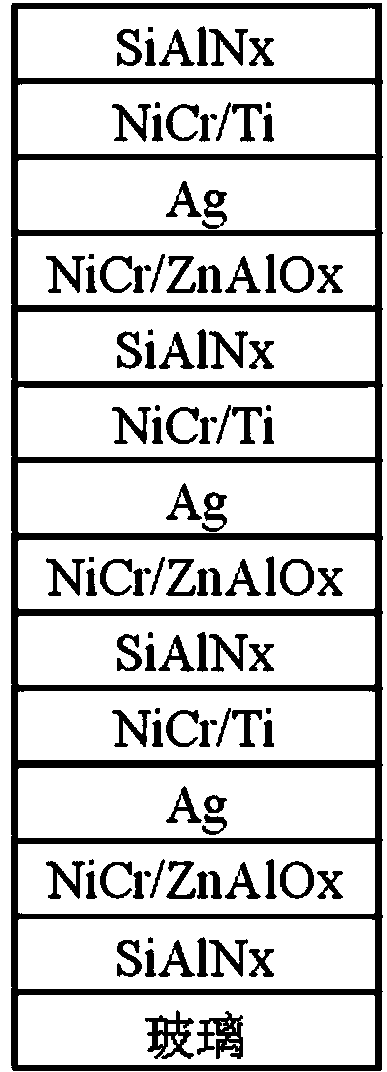

[0015] For the conventional scheme of film system design of existing off-line low-e coated glass, see Figure 1a , Figure 1b and Figure 1c : Since the Ag layer of the functional layer is protected by metal, it absorbs less light for visible light, and the attenuation of light is mainly reflected in light reflection. When designing some low-shade coating products, it is easy to produce higher light reflectivity and form light pollution. , and the inherent optical properties of thin-film metals have higher reflections for long-wave bands in visible light, but weaker reflections for short-wavelengths, and as the thickness of the metal film increases, the impact on the unevenness of light reflection is greater, so when designing low-shade coatings Due to the unevenness of the reflected light band in the product, it is easy to make the reflected color difficult to maintain a neutral color, especially when designing high-end double-silver and triple-silver products, which affects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com