Brick making equipment and method for rapid prototyping special-shaped bricks

A special-shaped brick, fast technology, applied in the direction of auxiliary forming equipment, forming pressure head, ceramic forming machine, etc., can solve the problems of unrealistic manufacturing and production, and achieve the goal of improving the yield of blocks, reliable demoulding operation, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

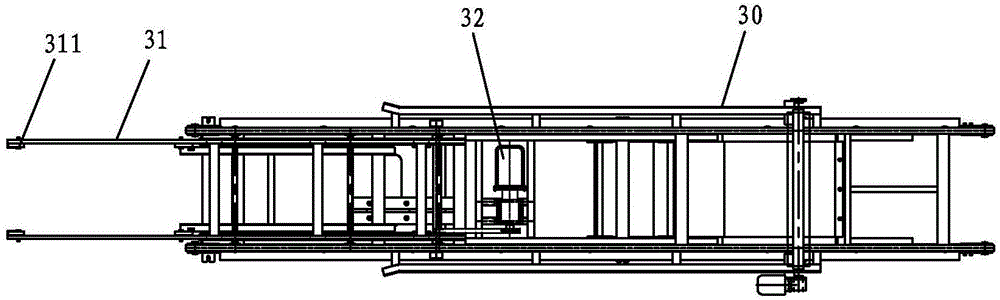

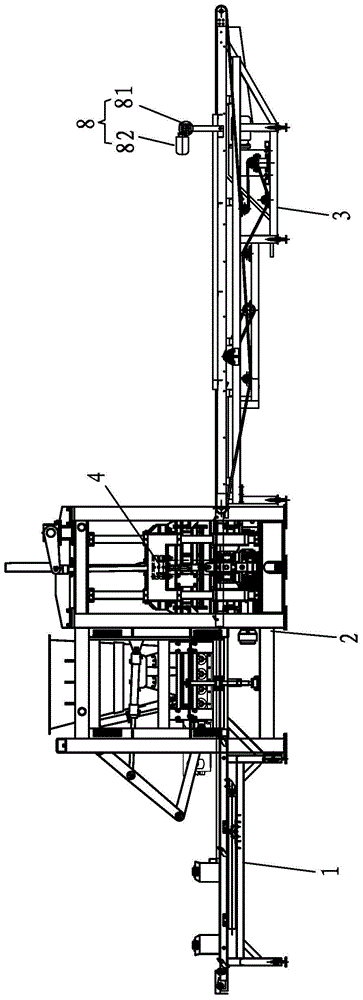

[0053] The present invention relates to a kind of brick-making equipment of rapid prototyping special-shaped brick, such as figure 1 As shown, it mainly includes a plate feeding machine 1, a block forming machine 2, a composite conveyor 3, a die connecting device 4 and a forming bottom plate 5.

[0054] The board feeding machine 1 is arranged at the rear end of the block forming machine 2, and is used to transfer the flat pallet to the vibrating table located below the block forming machine 2. The composite conveyor 3 is arranged at the front end of the block forming machine 2, and is used to take out the supporting plate with bricks from the supporting platform 6 of the block forming machine 2 and transport them out.

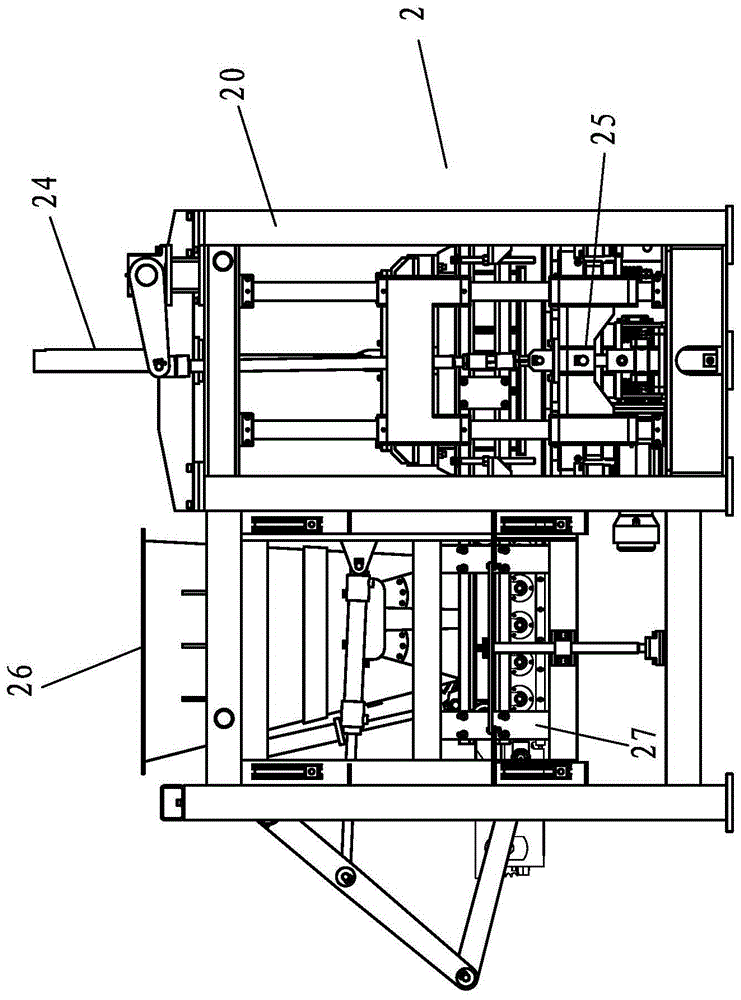

[0055] block forming machine 2 as Figure 2-3 As shown, it mainly includes a forming frame 20, a pressure head 21, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com