Static constant-tension control system for reciprocation high-speed wire traveling

A constant tension and control system technology, applied in electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problems of troublesome adjustment of electrode wire tension, difficulty in ensuring constant tension, wire resonance and jitter, etc., to solve the problem of inconsistent tension , The effect of solving the resonance and jitter of the electrode wire and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

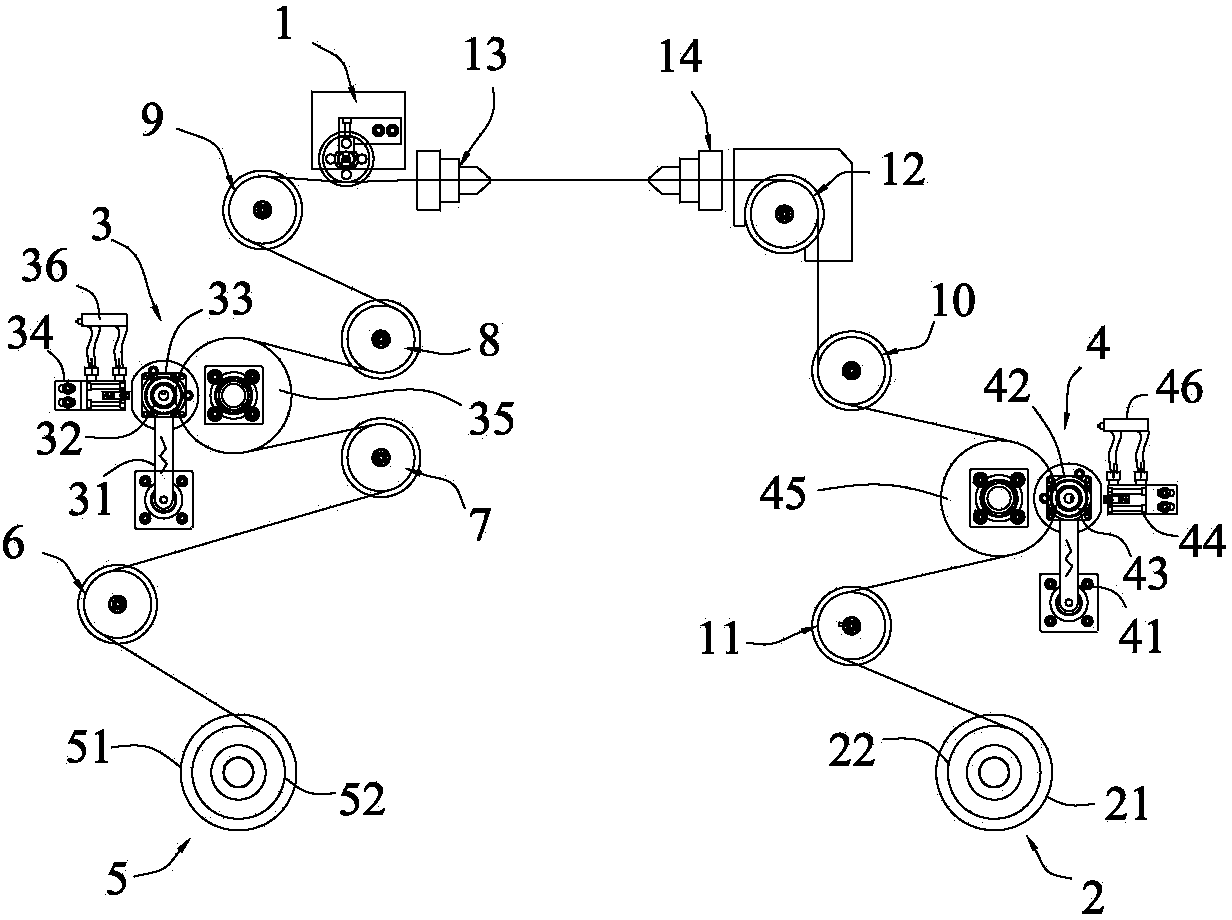

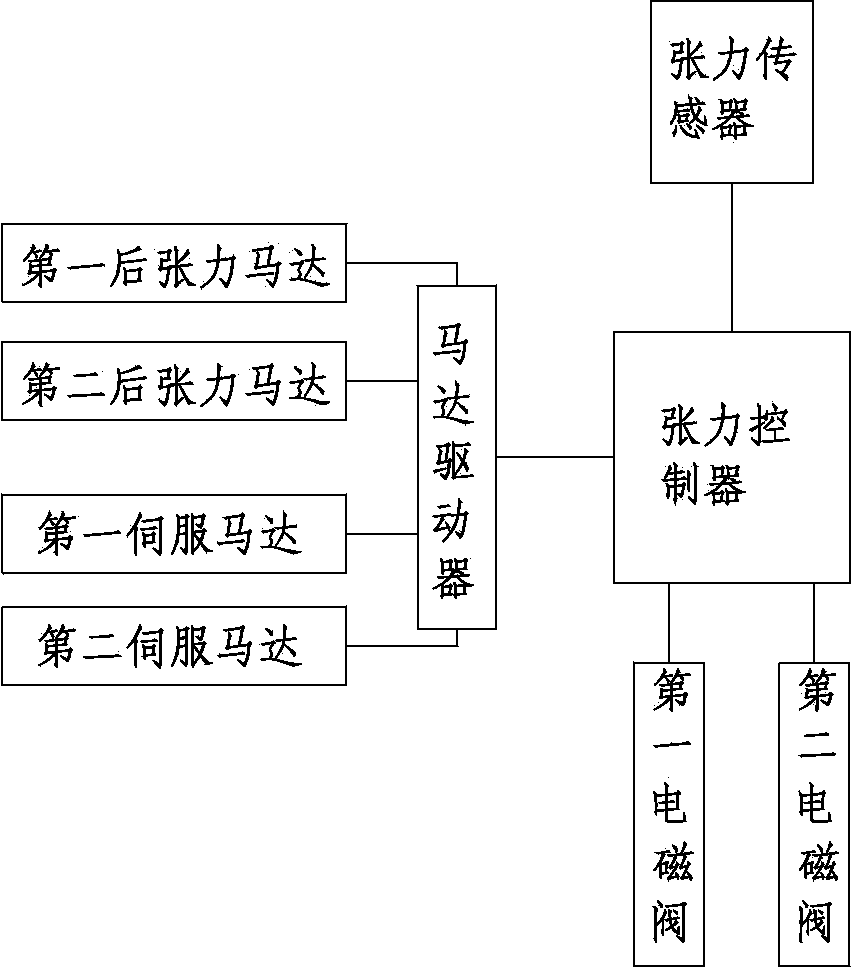

[0015] Example: see figure 1 and figure 2 , a reciprocating high-speed wire walking static constant tension control system provided in this embodiment, which includes a first wire guide wheel A6, a first wire guide wheel B7, a first wire guide wheel C8, a first wire guide wheel D9, a second wire guide wheel Guide wire wheel A10, second guide wire wheel B11, thread-entry guide pulley 12, tension controller and tension sensor 1 respectively connected to the tension controller, first wire feeding wheel retracting device 5, second wire feeding wheel The retracting device 2, the first constant tension adjusting device 3 and the second constant tension adjusting device 4, the electrode wire is sequentially wound through the first wire feeding wheel retracting device 5, the first guide wire wheel A6, the first guide wire wheel B7, The first constant tension adjusting device 3, the first guiding wire wheel C8, the first guiding wire wheel D9, the tension sensor 1, the thread-in guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com