Conductive polymer microcapsule of reactive liquid core material and preparation method thereof

A conductive polymer and microcapsule technology, which is applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., to achieve the effect of cheap raw materials, beneficial to industrial production, and easy to dry and collect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

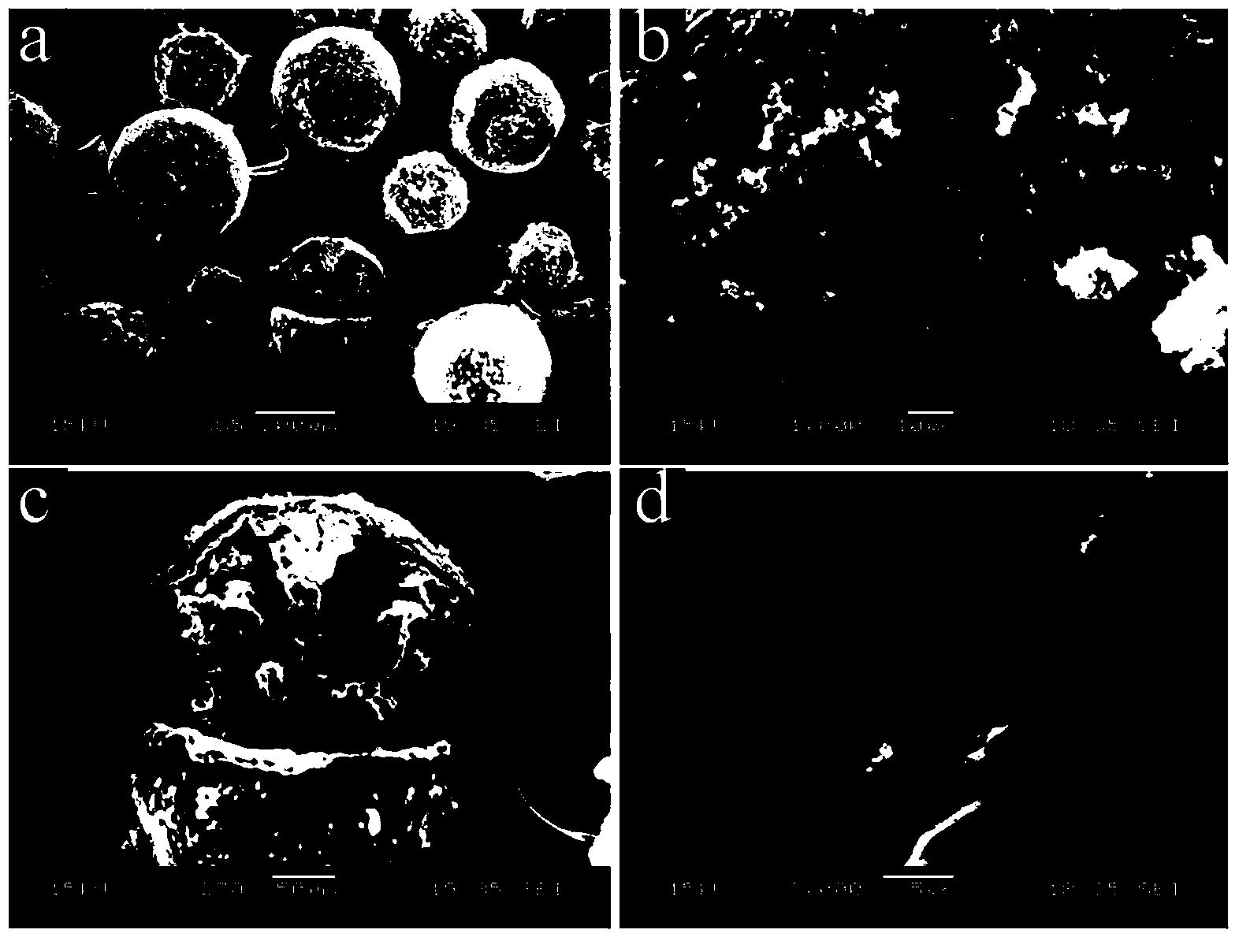

Embodiment 1

[0027]50 ml of an aqueous solution containing 3 wt % gum arabic was prepared at room temperature and heated to 40°C. 10 g of isocyanate (containing 8.5 g of HDI and 1.5 g of MDI prepolymer) was added to the above aqueous solution of gum arabic, and stirred at a speed of 600 rpm for 15 min. Then react at a stirring speed of 150 rpm for 90 min. After natural cooling, the product was washed 6 times with deionized water to obtain a suspension. At room temperature, add 35.56g of 15.64wt% ferric chloride (III) hydrochloric acid aqueous solution (that is, contain 5.56g of anhydrous ferric chloride and 30g0.1mol / l hydrochloric acid aqueous solution) in the above-mentioned suspension, and at a rotating speed of 200rpm Under mechanical stirring. After 10 minutes, a total of 31 g of 3.23 wt % pyrrole aqueous solution (ie containing 1 g of pyrrole and 30 g of water) was added to the system in 8 times at intervals of 10 minutes each time. After continuing to stir at room temperature for...

Embodiment 2

[0031] 50 ml of an aqueous solution containing 3 wt % gum arabic was prepared at room temperature and heated to 40°C. 10 g of isocyanate (containing 8.5 g of HDI and 1.5 g of MDI prepolymer) was added to the above aqueous solution of gum arabic, and stirred at a speed of 1200 rpm for 15 min. Then react at a stirring speed of 150 rpm for 90 min. After natural cooling, the product was washed 6 times with deionized water to obtain a suspension. At room temperature, add 35.56g of 15.64wt% ferric chloride (III) hydrochloric acid aqueous solution (that is, contain 5.56g of anhydrous ferric chloride and 30g0.1mol / l hydrochloric acid aqueous solution) in the above-mentioned suspension, and at a rotating speed of 200rpm Under mechanical stirring. After 10 minutes, a total of 31 g of 3.23 wt % pyrrole aqueous solution (ie containing 1 g of pyrrole and 30 g of water) was added to the system in 8 times at intervals of 10 minutes each time. After continuing to stir at room temperature f...

Embodiment 3

[0035] 50 ml of an aqueous solution containing 3 wt % gum arabic was prepared at room temperature and heated to 40°C. Add 10 g of isocyanate (containing 8.5 g of HDI dimer and 1.5 g of MDI prepolymer) to the above aqueous solution of gum arabic, and stir at 800 rpm for 10 min. Then react at a stirring speed of 150 rpm for 30 min. After natural cooling, the product was washed 6 times with deionized water to obtain a suspension. At room temperature, add 35.56g of 15.64wt% ferric chloride (III) hydrochloric acid aqueous solution (that is, contain 5.56g of anhydrous ferric chloride and 30g0.1mol / l hydrochloric acid aqueous solution) in the above-mentioned suspension, and at a rotating speed of 200rpm Under mechanical stirring. After 10 minutes, a total of 31 g of 3.23 wt % pyrrole aqueous solution (ie containing 1 g of pyrrole and 30 g of water) was added to the system in 8 times at intervals of 10 minutes each time. After continuing to stir at room temperature for 4.5 h, the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com