Method for preparing fructose by glucose catalysis

A glucose and fructose technology, applied in chemical instruments and methods, preparation of sugar derivatives, molecular sieve catalysts, etc., can solve the problems of cumbersome reaction process, low conversion of sugar raw materials, low fructose yield, etc., and achieve high selectivity, high High promotion and application value, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026]For the above preparation method, it can be selected to be carried out in a conventional reactor. In order to facilitate the control of reaction conditions, it is preferably carried out in a batch-type autoclave.

[0027]In order to verify the technical effect of the present invention, the fructose yield is used to evaluate the technical effect.

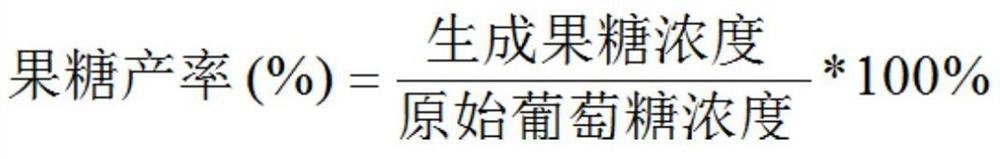

[0028]The formula for calculating fructose yield is:

[0029]

[0030]In the present invention, the content of fructose in the reaction liquid is analyzed by high performance liquid chromatography, and the instrument model is UltiMate 3000.

Embodiment 1

[0033]Dry the HY molecular sieve at 110°C for 3 hours, then immerse it in a 10% sodium nitrate solution at 90°C for 3 hours, then dry the impregnated HY molecular sieve at 90°C for 2 hours, after grinding, and then increase the temperature according to the roasting At a rate of 5°C / min, the temperature is raised to 600°C and then heat-retained and roasted for 3 hours to obtain a modified HY molecular sieve;

[0034]1.5g glucose was contacted with 0.15g modified HY molecular sieve catalyst in methanol-water medium (28.5ml methanol and 1.5ml water) at 120℃ for 2 hours. After the reaction, the reaction solution was cooled and analyzed by high performance liquid chromatography The results showed that the fructose yield was 42.5%.

Embodiment 2

[0040]The implementation steps and conditions were the same as in Example 1, except that the sodium nitrate solution was replaced with sodium acetate solution. After the reaction, the reaction solution was cooled and analyzed by high performance liquid chromatography. The result showed that the fructose yield was 38.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com