Method for reducing NOx in smoke through ammonia source of household garbage

A technology for household waste and removal, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve problems such as increased operating costs and unsatisfactory NO absorption effect, and achieves lower treatment costs, better treatment effects, and improved production. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

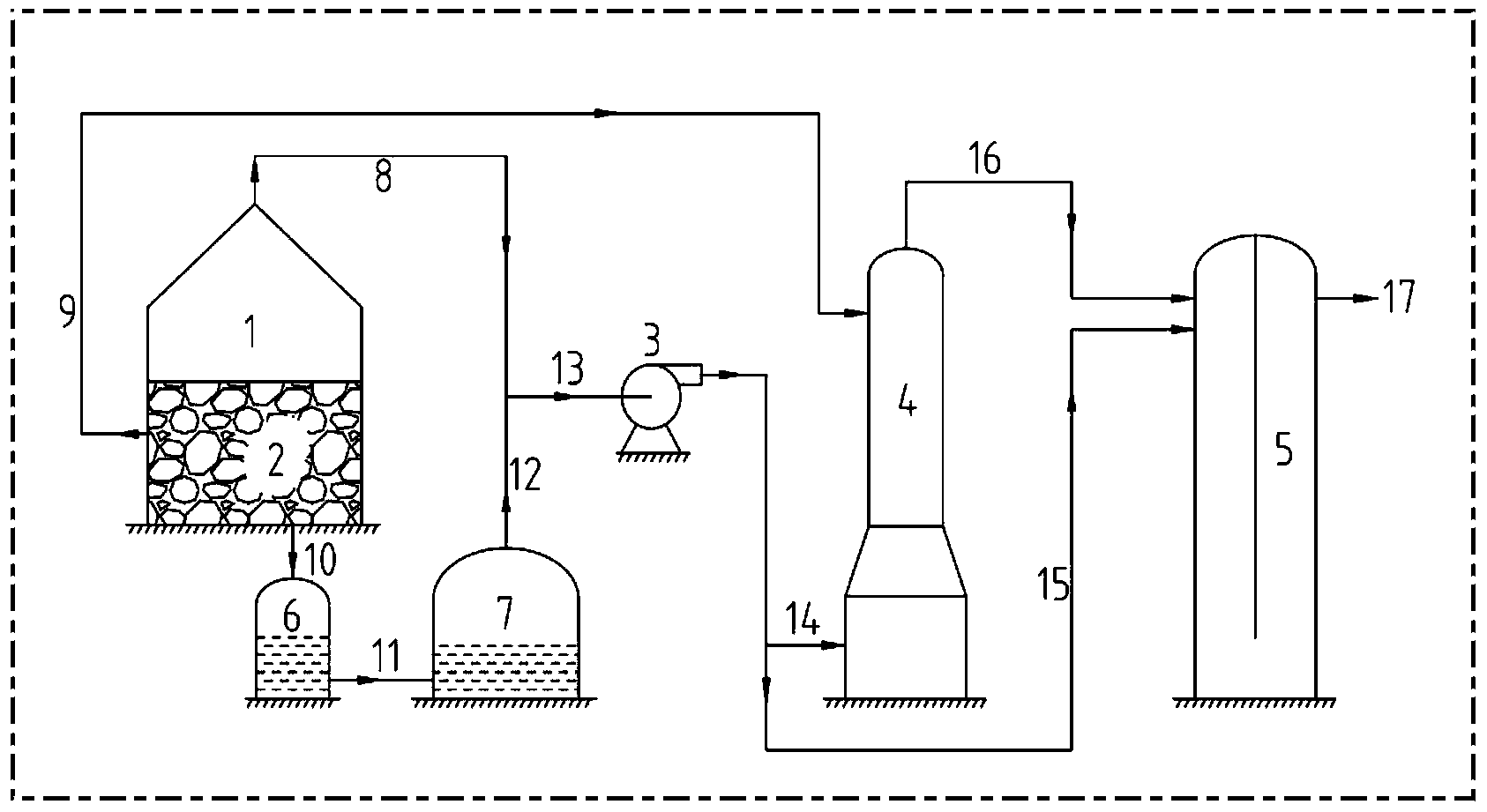

[0027] Example 1: A pyrolysis gasification treatment device for domestic waste, the size of the gasifier and the combustion system are respectively Φ1800×4500mm and 3000×2500×6000mm, and the daily processing capacity is 120t. Household waste is fermented in Heap 1 for 7 days at a fermentation temperature of 48°C. During, it will release the NH containing 3 and H 2 S, CH 4 、H 2 O.CO 2 The degraded gas of equal composition, it will be exported through rubbish degraded gas output pipeline 8 together with the air in the stacker;

[0028] Step 2: Due to fermentation, domestic waste will release leachate at the same time, it will enter the landfill leachate collection tank through landfill leachate pipeline one 10, and then enter the methanation biogas fermentation tank 7 through landfill leachate pipeline two 11, biogas The biogas in the pool 7 is exported through the biogas output pipeline 12;

[0029] Step 3: Degradation gas, biogas and air will pass through the mixed gas p...

Embodiment 2

[0031]Example 2: In a direct incineration treatment device for domestic waste, the dimensions of the gasifier and combustion system are Φ2400×5200mm and 4000×3000×6500mm respectively, and the daily processing capacity is 300t. Household waste is fermented in Heap 1 for 5 days at a fermentation temperature of 45°C. Afterwards, after operating as step 1 to step 4 of Example 1, finally in the upper part of the incinerator (combustion system), the NOx in the flue gas and the ammonia in the mixed gas of ammonia and air sent by the blower 3 generate reaction. At this time, the average temperature of the upper part of the incinerator (combustion system) was 862°C. After the reaction, the flue gas flow rate discharged from the combustion system through pipeline 17 is 52500Nm 3 / h, including NOx=78mg / Nm 3 , the residual ammonia content is 3mg / Nm 3 , it will be removed through subsequent water washing, desulfurization and other operations.

Embodiment 3

[0032] Example 3: A direct incineration treatment device for domestic waste, the size of the gasifier and the combustion system are respectively Φ3000×6200mm and 5000×4500×7000mm, and the daily processing capacity is 500t. Household waste is fermented in Heap 1 for 6 days at a fermentation temperature of 46°C. Afterwards, after operating as step 1 to step 4 of Example 1, finally in the upper part of the incinerator (combustion system), the NOx in the flue gas and the ammonia in the mixed gas of ammonia and air sent by the blower 3 generate reaction. At this time, the average temperature of the upper part of the incinerator (combustion system) is 885°C. After the reaction, the flue gas flow rate discharged from the combustion system through pipeline 17 is 87680Nm 3 / h, including NOx=91mg / Nm 3 , the residual ammonia content is 5mg / Nm 3 , it will be removed through subsequent water washing, desulfurization and other operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com