Detection method for repeated position defects in batch of wafers

A wafer batch and detection method technology, applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as complex operation, defects at the same position in lithography, and difficult to identify circuit defects without consideration, to achieve The effect of reducing the possibility of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention provides a high-sensitivity detection method for repeated position defects, which can be applied to processes with technical nodes of 90nm, 65 / 55nm, 45 / 40nm, 32 / 28nm, 130nm or more and 22nm or less; and can be applied to the following Technology platforms: Logic, Memory, RF, HV, Analog / Power, MEMS, CIS, Flash and eFlash.

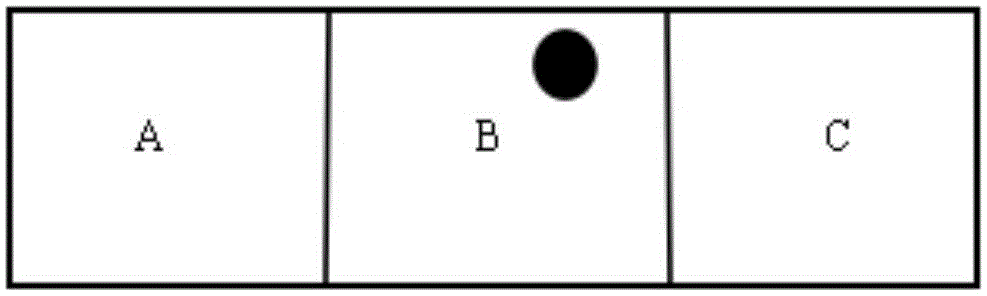

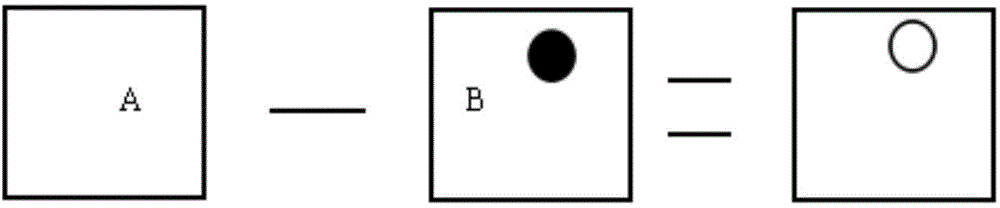

[0037] Such as Figure 6-10 As shown, the present invention is a method for detecting repeated position defects in a wafer batch, and the method includes:

[0038] Step S1: Provide a batch of wafers for defect detection, and establish the same coordinate system on each of the wafers;

[0039] Step S2: Obtain all defect positions on each of the wafers, and obtain corresponding defect coordinates according to the coordinate system;

[0040] Step S3, comparing the coordinate of the defect on any one of the wafers with the coordinate of the defect on each of the other wafers, so as to mark the coordinate of the defect that is repeated at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com