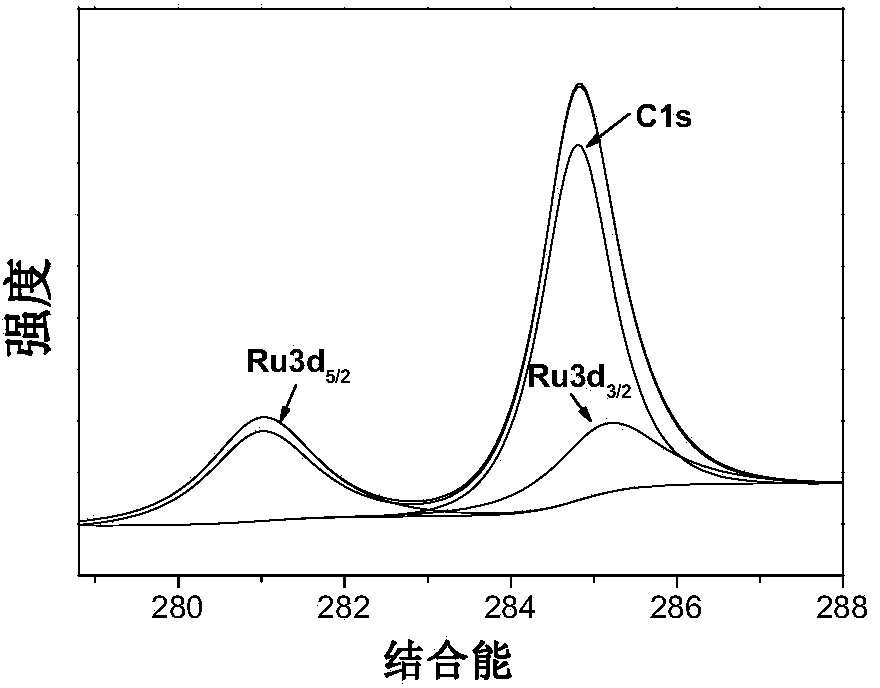

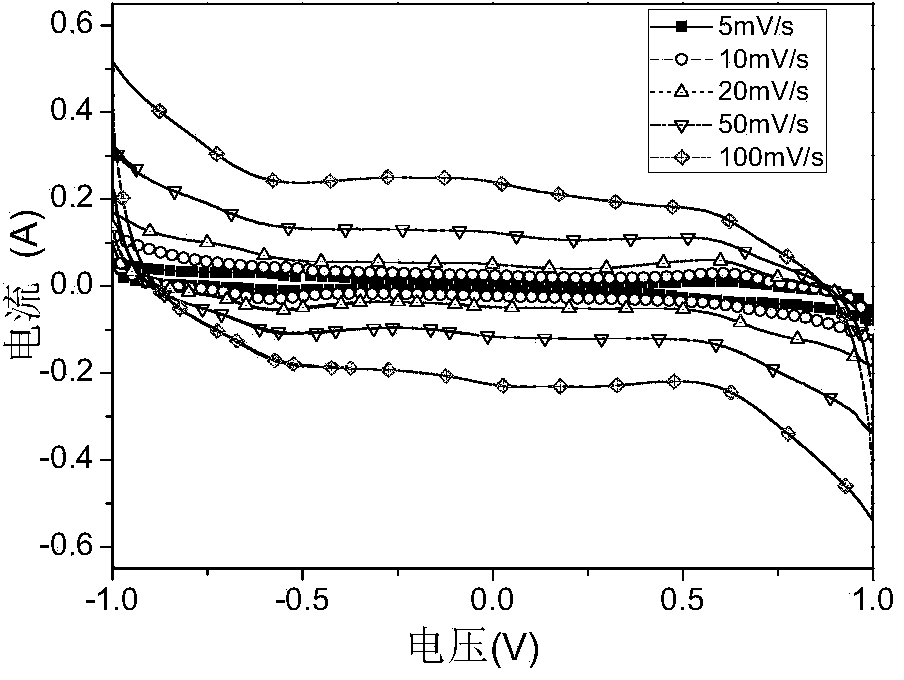

Ruthenium dioxide/carbon composite nano-material for super capacitor, and preparation method thereof

A technology of supercapacitors and carbon composite materials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of low yield, complex material process, low adhesion strength, etc. The effect of simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Accurately weigh 2.09 mg of ruthenium trichloride hydrate, add it into 15 ml of distilled water, stir and disperse for 5 minutes, so that the ruthenium trichloride is fully dissolved. Then measure 15 mL of ethanol, add it to the above solution, stir and disperse for 5 minutes, so that the two solutions are fully mixed. 0.15 mL of dodecylamine was weighed and dissolved into the above solution, and the solution was magnetically stirred at room temperature for 30 minutes. The obtained mixed solution was put into an autoclave with a polytetrafluoroethylene liner, sealed, and kept at a constant temperature of 160° C. for 3 hours. The product was washed with absolute ethanol, dispersed in toluene solution, then centrifuged and washed with absolute ethanol, and then redispersed in toluene. In the obtained dispersion liquid, add 0.62mg activated carbon, stir and adsorb for 12 hours. Then centrifuge and wash with ethanol for 5 times, boil with acetic acid for 3 hours, wash wit...

Embodiment 2

[0052] Accurately weigh 4.18 mg of ruthenium trichloride hydrate, add it into 15 ml of distilled water, stir and disperse for 10 minutes, so that the ruthenium trichloride is fully dissolved. Then measure 20 mL of ethanol, add it to the above solution, stir and disperse for 10 minutes, so that the two solutions are fully mixed. Weigh 0.4 mL of dodecylamine and dissolve it into the above solution, and magnetically stir the solution at room temperature for 40 minutes. The obtained mixed solution was put into an autoclave with a polytetrafluoroethylene liner and sealed, and kept at a constant temperature of 100° C. for 6 hours. The product was washed with absolute ethanol, dispersed in toluene solution, then centrifuged and washed with absolute ethanol, and then redispersed in toluene. In the obtained dispersion liquid, add 2.46mg activated carbon, stir and adsorb for 2 hours. Then centrifuge and wash with ethanol for 5 times, boil with acetic acid for 3 hours, wash with water ...

Embodiment 3

[0054] Accurately weigh 8.35 mg of ruthenium trichloride hydrate, add it into 15 ml of distilled water, stir and disperse for 15 minutes, so that the ruthenium trichloride is fully dissolved. Then measure 30 mL of ethanol, add it to the above solution, stir and disperse for 15 minutes, so that the two solutions are fully mixed. Weigh 1.2 mL of dodecylamine and dissolve it into the above solution, and magnetically stir the solution at room temperature for 50 minutes. The obtained mixed solution was put into an autoclave with a polytetrafluoroethylene liner and sealed, and kept at a constant temperature of 120° C. for 9 hours. The product was washed with absolute ethanol, dispersed in toluene solution, then centrifuged and washed with absolute ethanol, and then redispersed in toluene. In the obtained dispersion liquid, add 9.86mg activated carbon, stir and adsorb for 4 hours. Then centrifugal ethanol was washed 5 times, boiled with acetic acid for 3 hours, washed 3 times with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com