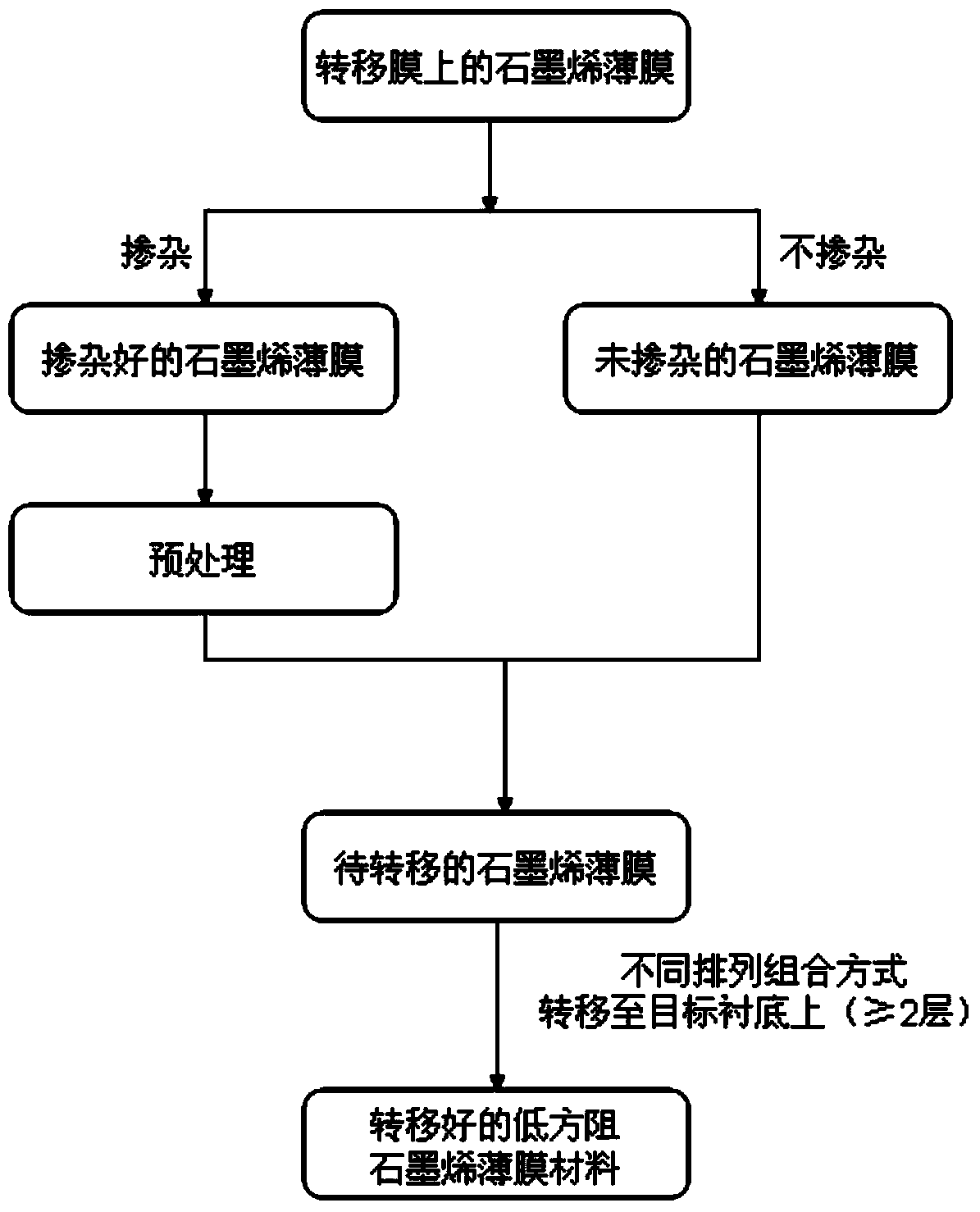

Dope-transferring method for reducing sheet resistance of graphene

A transfer method and graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of easy defect of graphene and high square resistance of graphene film, and achieve low cost, good integrity, The effect of reducing exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

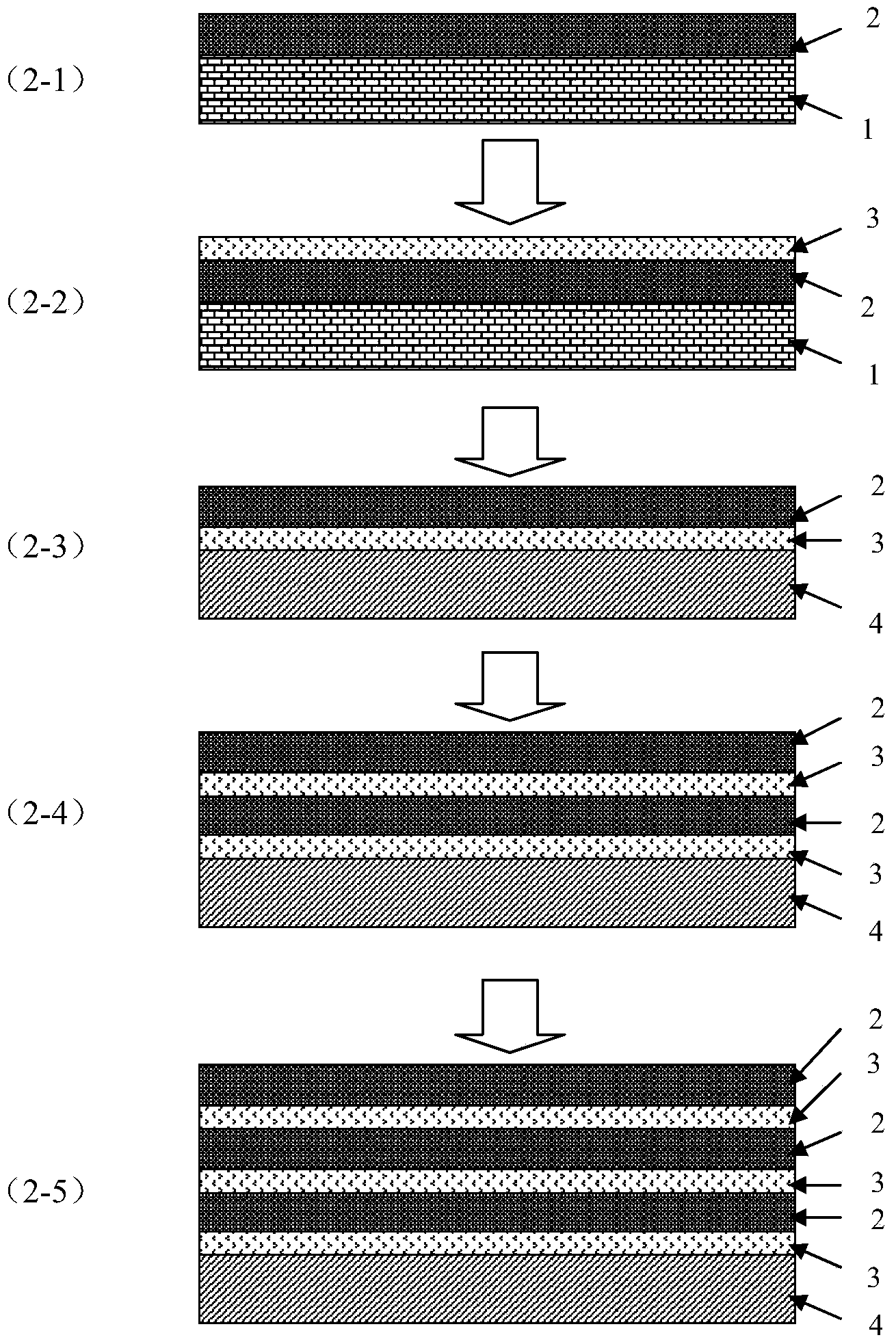

[0032] 1. Put the transfer film / graphene etched with hydrochloric acid into deionized water to wash away the impurities adsorbed on the graphene surface. Take it out, blow it dry, and bake it at 80°C for 15 minutes to obtain the transfer film / graphene;

[0033] 2. Dope the transfer film / graphene with 1mol / L doping agent (referred to as Fe) prepared by ferric chloride and nitromethane. The doping method is spraying for 2 minutes, then baking at 50°C for 3 minutes, and the transfer film is obtained after dust removal. / graphene / Fe; dope the transfer film / graphene with 1mmol / L doping agent (denoted as Ca) prepared by calcium chloride and absolute ethanol. The doping method is to spray for 10min, then dry and remove dust to obtain transfer film Membrane / graphene / Ca;

[0034] 3. Transfer film / graphene / Fe to glass to obtain glass / Fe / graphene / transfer film, bake at 80°C for 15 minutes, take it out and peel off the transfer film to obtain glass / Fe / graphene;

[0035] 4. Transfer the ...

Embodiment 2

[0038] 1. Put the transfer film / graphene etched with hydrochloric acid into deionized water to wash away the impurities adsorbed on the graphene surface. Take it out, blow it dry, and bake it at 150°C for 1 minute to obtain the transfer film / graphene;

[0039] 2. Dope the transfer film / graphene with a 500mmol / L doping agent (referred to as TFSA) prepared from bistrifluoromethanesulfonylimide (TFSA) and nitromethane. The doping method is to spray for 2min, then 50°C Baking for 3 minutes, dedusting to obtain transfer film / graphene / TFSA;

[0040] 3. Transfer the transfer film / graphene / TFSA (referred to as TFSA) to an acrylic plate to obtain an acrylic plate / TFSA / graphene / transfer film, bake at 90°C for 20 minutes, remove the transfer film, and obtain an acrylic plate / TFSA / Graphene;

[0041] 4. Transfer the film / graphene / TFSA to the acrylic plate / TFSA / graphene in step 3, bake at 90°C for 20 minutes, remove the transfer film, and obtain the acrylic plate / TFSA / graphene / TFSA / graph...

Embodiment 3

[0044] 1. Put the transfer film / graphene etched with hydrochloric acid into deionized water to wash away the impurities adsorbed on the graphene surface. Take it out, blow it dry, and bake at 30°C for 10 hours to obtain the transfer film / graphene;

[0045] 2. Dope the transfer film / graphene with 100mmol / L doping reagent (referred to as Fe) prepared by ferric chloride and nitromethane. The doping method is spin coating for 30s, then baked at 50°C for 3min, and the transfer film is obtained after dust removal. Membrane / graphene / Fe; dope transfer film / graphene with 100mmol / L doping agent (referred to as HCl) prepared by hydrochloric acid and water, the doping method is spin coating for 30s, then dried and dedusted to obtain transfer film / graphene Graphene / Ca;

[0046] 3. Transfer film / graphene / Fe to polyethylene terephthalate (referred to as PET) to obtain PET / Fe / graphene / transfer film, bake at 90°C for 20min, take out and peel off the transfer film to obtain PET / Fe / graphene; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com