A high-strength plastic vanadium microalloyed dual-phase steel seamless pipe and its preparation method

A seamless tube and alloying technology, which is applied in the direction of manufacturing tools, heat treatment equipment, and energy efficiency improvement, can solve the problems of inability to produce large-sized and long steel tubes, slow heating, and application limitations, and achieves further development and broad application. Prospects, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The chemical composition of the steel used in this embodiment is C: 0.10%, Si: 0.42%, Mn: 1.32%, V: 0.16%, N: 0.01%, P: 0.004%, S: 0.003%, and the balance For Fe and unavoidable impurities.

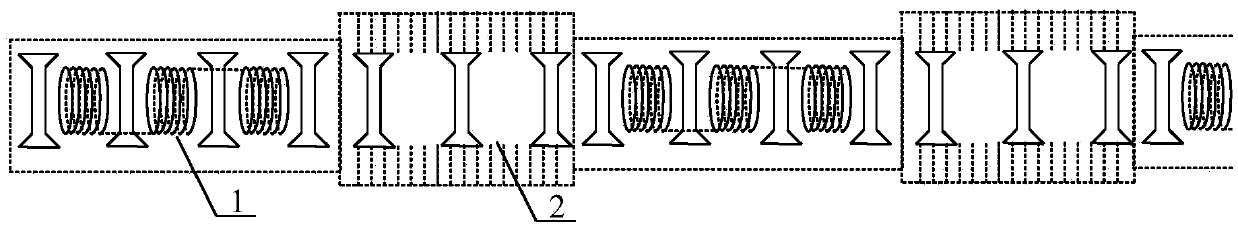

[0051] The smelted ingot is forged into a bar, and the bar is turned to remove wrinkles and defects on the outer surface to form a tube billet. The tube billet is heated to 1200°C and kept for 2 hours before piercing, and then cooled to room temperature. The tube blank is cold-drawn for 5 passes to obtain a seamless cold-drawn steel tube with a wall thickness of 1.5 mm and an outer diameter of 46 mm.

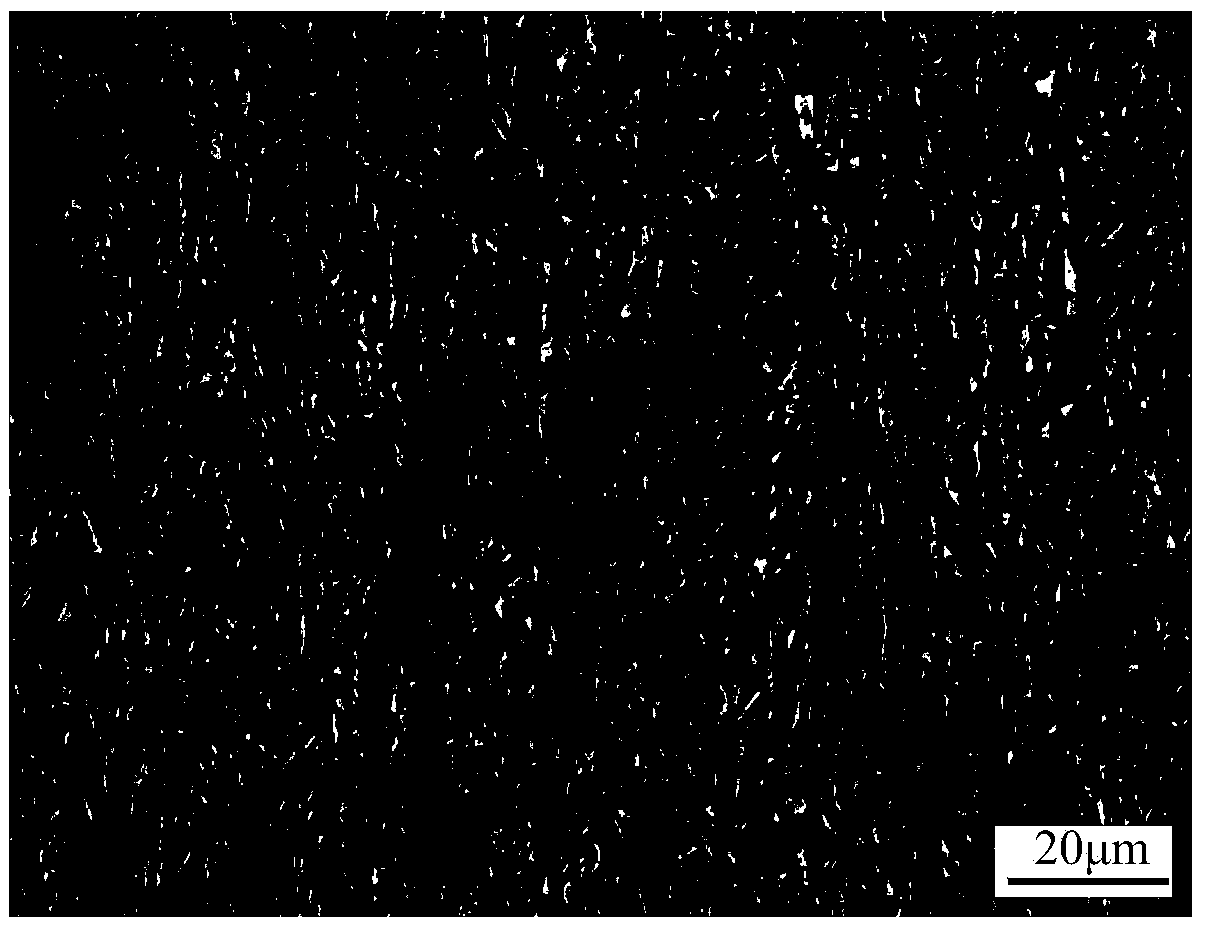

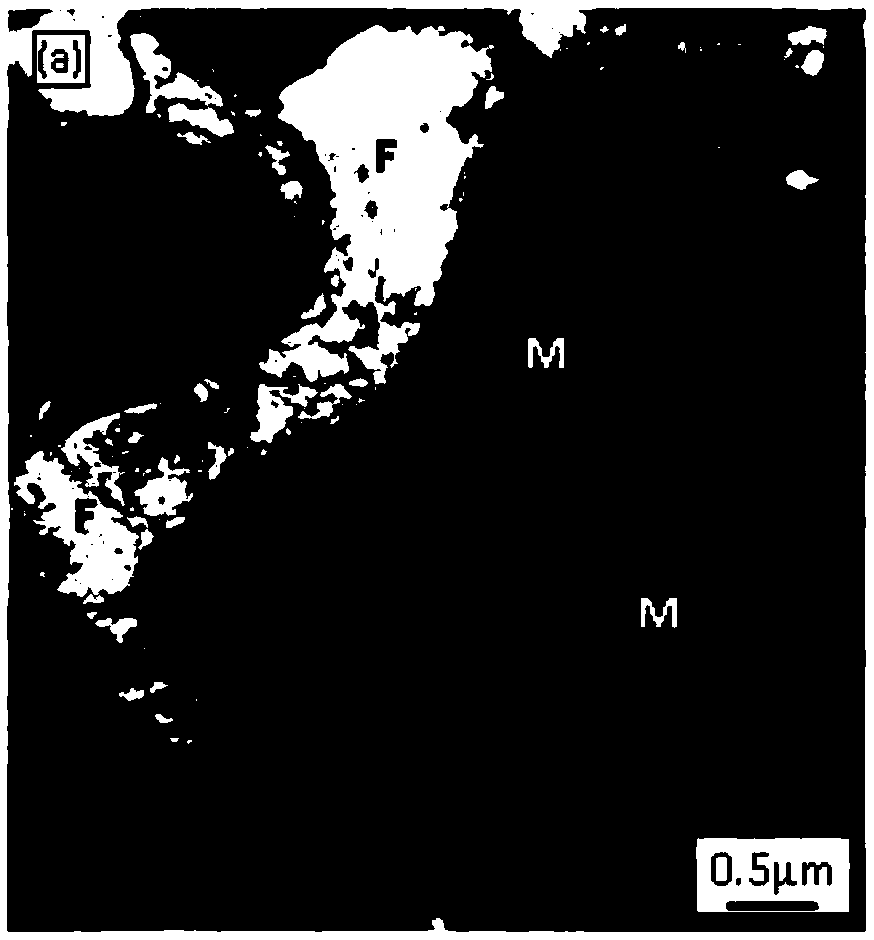

[0052] The cold-drawn seamless steel pipe is heated to a two-phase region of 780-820°C at a rate of about 10°C / s by an intermediate-frequency heating induction coil, annealed for 20-40s, and then cooled naturally at a rate of about 3°C / s. Cool to 650-690°C (this temperature is referred to as the initial temperature of rapid cooling in the table); then use compressed air to cool to 2...

Embodiment 2

[0059] The chemical composition of steel selected in this embodiment is C: 0.13%, Si: 0.10%, Mn: 1.60%, V: 0.17%, N: 0.019%, P: 0.006%, S: 0.004%, and the balance For Fe and unavoidable impurities.

[0060] The smelted ingot is forged into a bar, and the bar is turned to remove wrinkles and defects on the outer surface to form a tube blank. The tube blank is heated to 1150°C and kept for 2 hours before piercing, and then cooled to room temperature. The tube blank is cold-drawn for 4 passes to obtain a seamless cold-drawn steel tube with a wall thickness of 2.0 mm and an outer diameter of 55 mm.

[0061] The cold-drawn seamless steel pipe is heated to a two-phase region of 790-820°C at a rate of about 20°C / s by a medium-frequency heating induction coil, annealed for 20-40s, and then cooled by air at a rate of about 5°C / s. Cool to 640-690°C; then use compressed air to cool at a rate of about 60°C / s to 260-280°C for isothermal treatment for 60-120s; finally air-cool to room temp...

Embodiment 3

[0067] The chemical composition of the steel used in this embodiment is C: 0.15%, Si: 0.60%, Mn: 1.10%, V: 0.17%, N: 0.021%, P: 0.004%, S: 0.005%, and the balance For Fe and unavoidable impurities.

[0068]The smelted ingot is forged into a bar, and the bar is turned to remove wrinkles and defects on the outer surface to form a tube blank. The tube blank is heated to 1250 ° C and kept for 3 hours before piercing, and then cooled to room temperature. The tube blank is cold-drawn for 4 passes to obtain a seamless cold-drawn steel tube with a wall thickness of 1.20 mm and an outer diameter of 41 mm.

[0069] The cold-drawn seamless steel pipe is heated to a two-phase region of 780-810°C at a rate of about 10°C / s by an intermediate frequency heating induction coil, and after annealing for 10-20s, it is cooled by air at a rate of about 4°C / s. Cool to 640-680°C; then use compressed air to cool at a rate of about 50°C / s to 250-270°C for isothermal treatment for 100-160s; finally coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com